Repair And Upgrading Of The 240sx Headlight Wiring Harness

The Nissan 240SX, beloved by enthusiasts for its drift-friendly chassis and relatively simple mechanics, often suffers from a common ailment: headlight wiring issues. Age, environmental factors, and modifications can all contribute to voltage drops, flickering lights, or even complete headlight failure. While a simple bulb replacement is often the first step, sometimes the root cause lies deeper within the wiring harness itself. This guide dives into the intricacies of diagnosing, repairing, and even upgrading your 240SX's headlight wiring harness.

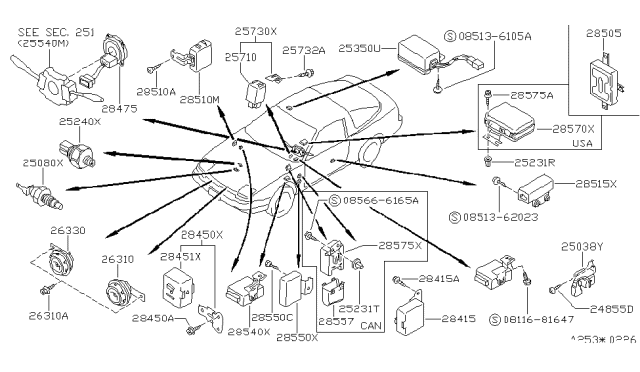

Understanding the Stock 240SX Headlight Circuit

Before tackling any repairs or upgrades, it's crucial to understand how the stock headlight circuit operates. In the 240SX (S13 and S14 generations), the headlights are controlled through a relatively basic system. Power flows from the battery, through the ignition switch, to the headlight switch, and then to a combination switch (stalk) on the steering column. From there, the signal is sent to the headlight relays. These relays, located in the engine bay near the battery, act as electrically controlled switches. When activated, they allow a higher current, direct path from the battery to the headlights.

The key components to remember are:

- Battery: The source of power.

- Ignition Switch: Enables the headlight circuit when the car is running.

- Headlight Switch: Turns the headlights on and off.

- Combination Switch (Stalk): Controls high beams and low beams.

- Headlight Relays: Actuate the high-current circuit to the headlights.

- Headlight Bulbs: The illumination source.

- Wiring Harness: The network of wires connecting all these components.

Understanding this flow is paramount. Voltage drop, the bane of headlight performance, occurs when resistance in the wiring harness impedes the flow of current. This can be caused by corroded connectors, frayed wires, or undersized wiring, leading to dim or flickering headlights.

Diagnosing Headlight Wiring Problems

Before blindly replacing components, a systematic diagnosis is essential. Here's a step-by-step approach:

1. Visual Inspection

Begin with a thorough visual inspection of the entire headlight wiring harness. Look for:

- Corroded Connectors: Check all connectors, especially those near the battery and headlights. Green or white deposits indicate corrosion.

- Frayed Wires: Inspect the wiring insulation for cracks, cuts, or abrasions. Pay close attention to areas where the harness rubs against the chassis or engine components.

- Melted Wiring: This is a sign of excessive current draw or a short circuit.

- Loose Connections: Ensure all connections are secure and properly seated.

2. Voltage Drop Testing

Voltage drop testing is a crucial technique for identifying areas of high resistance. Here's how to perform it:

- Set up your multimeter: Set your multimeter to the DC voltage setting.

- Turn on the headlights: With the engine running, turn on the headlights.

- Test across connections: Place one probe of the multimeter on one side of a connection (e.g., the battery terminal) and the other probe on the other side of the connection (e.g., the connector leading to the relay).

- Interpret the results: A significant voltage drop (more than 0.5 volts) indicates a problem in that section of the wiring. A lower voltage drop (under 0.2V) is usually normal.

Example: If you measure a 1.0-volt drop between the battery positive terminal and the power input of the headlight relay, there is excessive resistance in that section of the wiring. Trace the wire and connector and look for corrosion.

3. Ground Testing

A bad ground can also cause headlight problems. Test the ground connections using the same voltage drop method as above. Connect one multimeter lead to the negative battery terminal and the other to the headlight ground point. A significant voltage drop indicates a poor ground connection.

4. Relay Testing

Relays can fail over time. You can test them using a multimeter or by swapping them with a known good relay (from another circuit, such as the horn). To test with a multimeter, check for continuity between the coil terminals and the switch terminals when the relay is activated.

Repairing the Headlight Wiring Harness

Once you've identified the problem area, you can begin the repair process. Here are some common repairs:

1. Connector Repair/Replacement

Corroded connectors are a frequent issue. You can attempt to clean them with a wire brush and electrical contact cleaner. However, severely corroded connectors should be replaced. When replacing connectors, use high-quality, weatherproof connectors designed for automotive use. Be sure to crimp the connectors properly and use heat shrink tubing to protect the connections from moisture.

2. Wire Repair

Frayed or damaged wires should be repaired or replaced. If the damage is minor, you can splice in a new section of wire. Use appropriately sized wire (gauge) that matches the original wire. Stagger the splices to prevent a bulge in the harness. Always solder the connections and use heat shrink tubing for insulation and weather protection. For major damage to a significant section of the harness, consider replacing the entire section of wire.

3. Ground Repair

Ensure that all ground connections are clean and secure. Sand down the metal surface where the ground wire is attached to bare metal. Use a star washer to ensure a good connection. Apply dielectric grease to prevent corrosion.

Upgrading the Headlight Wiring Harness

Many 240SX owners choose to upgrade their headlight wiring harness to improve headlight performance and reliability. An upgraded harness typically features thicker gauge wiring and higher-quality relays, reducing voltage drop and providing brighter headlights.

Benefits of Upgrading

- Increased Brightness: Reduced voltage drop results in more power reaching the headlights, making them brighter.

- Improved Reliability: Thicker gauge wiring and better relays are more durable and less prone to failure.

- Reduced Load on Switches: Relays handle the high current, reducing the load on the headlight switch and combination switch.

Types of Upgraded Harnesses

Several aftermarket headlight wiring harnesses are available for the 240SX. These harnesses typically include:

- Thicker Gauge Wiring: Usually 12 or 14 gauge wire, compared to the stock harness's thinner gauge wire.

- High-Quality Relays: More robust relays that can handle higher current loads.

- Fused Protection: In-line fuses to protect the circuit from overloads.

- Plug-and-Play Connectors: Designed to connect directly to the existing headlight connectors, making installation relatively straightforward.

Installation Process

The installation process for an upgraded headlight wiring harness typically involves:

- Disconnect the Battery: Always disconnect the battery before working on electrical systems.

- Locate the Stock Headlight Connectors: These are located near the headlights.

- Connect the New Harness: Plug the new harness into the stock headlight connectors.

- Mount the Relays: Securely mount the relays in a suitable location in the engine bay.

- Connect to the Battery: Connect the harness to the battery positive terminal and ground.

- Test the Headlights: Verify that the headlights are working correctly.

When installing an upgraded harness, pay close attention to the instructions provided by the manufacturer. Ensure that all connections are secure and properly insulated. Properly routing the wiring to avoid rubbing or chafing is critical to long term reliability.

DIY Harness Build Considerations

For the more adventurous, building your own upgraded harness is an option. If you choose to do so, you need to select appropriately sized wiring (12 or 14 gauge is recommended), high-quality relays (30-40 amp), fuses, and connectors. Be sure to use proper crimping tools and soldering techniques to ensure reliable connections. Incorrect wiring can cause shorts, fires, and damage to your electrical system. Proceed with caution if you are not experienced with automotive wiring.

Final Thoughts

Maintaining and upgrading your 240SX's headlight wiring harness is a crucial step in ensuring safe and reliable operation. By understanding the stock circuit, performing thorough diagnostics, and using high-quality components, you can significantly improve headlight performance and prevent future wiring problems. Whether you choose to repair the existing harness or upgrade to a new one, the effort will be well worth it for improved visibility and peace of mind. Always remember to prioritize safety and consult with a qualified professional if you are unsure about any aspect of the repair or upgrade process.