Small Block Chevy Motor Mount Adapter Plate Specifications

So, you're swapping a Small Block Chevy (SBC) into something… interesting. Maybe it's a classic truck, a hot rod project, or even replacing a tired engine in an older car. That's great! SBCs are reliable, powerful, and parts are readily available. But, like many engine swaps, you've hit a snag: the motor mounts. The original engine mounts on your project vehicle likely don't line up with the mounting bosses on your SBC. Don't worry, you're not alone, and that's where SBC motor mount adapter plates come in.

Understanding the Motor Mount Dilemma

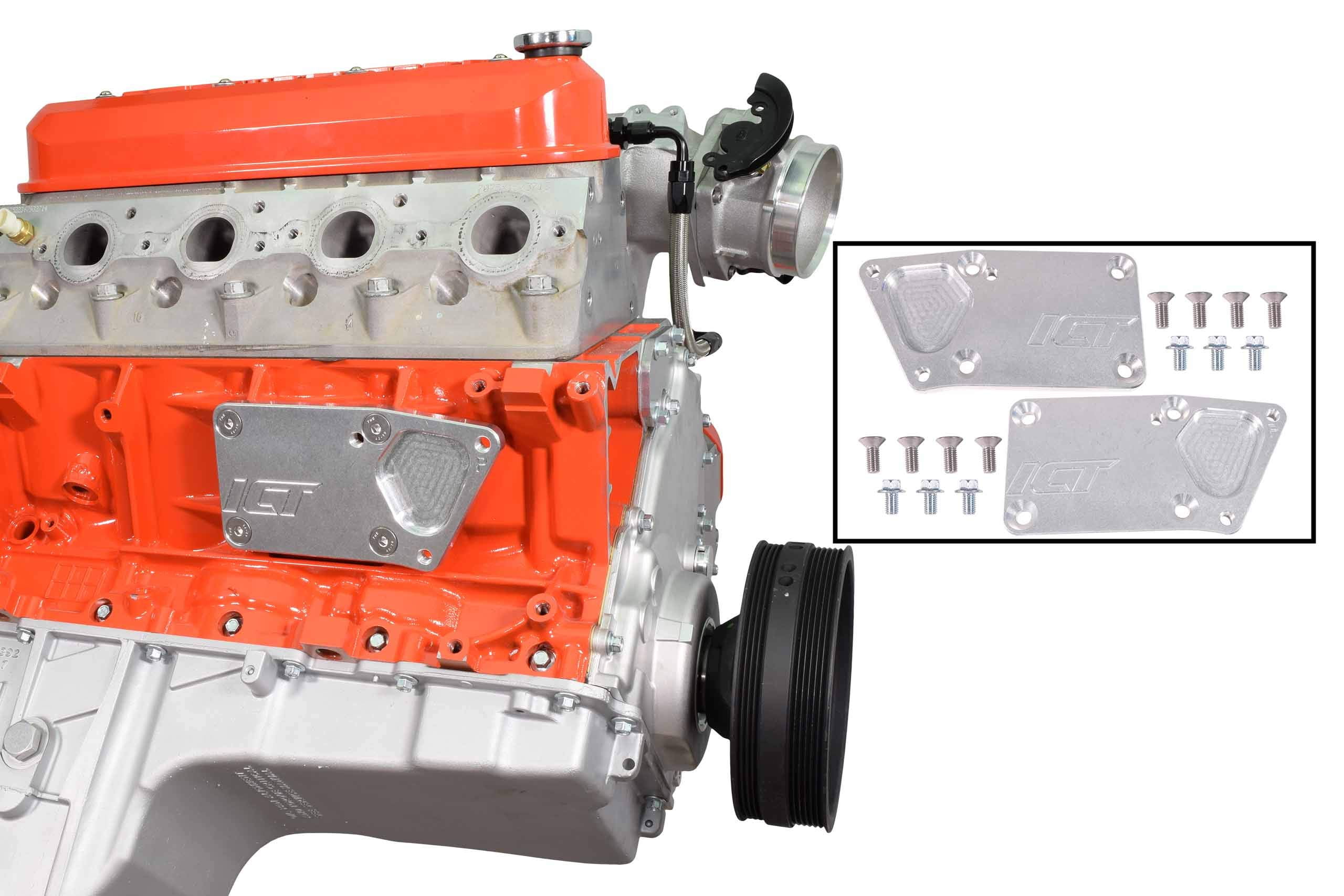

The challenge arises because engine mount designs have evolved over the years. Your target vehicle's original engine (likely something other than an SBC) probably used a different motor mount configuration. SBCs themselves also saw variations over their lifespan. Adapter plates bridge this gap, allowing you to bolt your SBC to the existing frame mounts. They are typically made from steel or aluminum and are designed to be strong enough to handle the engine's weight and torque.

Why Adapter Plates?

You might be thinking, "Why not just fabricate my own mounts or weld new ones onto the frame?" While that's certainly an option for skilled fabricators, adapter plates offer several advantages:

- Ease of Installation: Adapter plates are a bolt-on solution. This drastically reduces the amount of time and effort required for the swap. No welding, cutting, or complex fabrication is necessary.

- Reversibility: If you ever decide to revert to the original engine configuration (perhaps for a restoration project), you can simply unbolt the adapter plates. Welding, on the other hand, is permanent.

- Cost-Effectiveness: While the initial cost of adapter plates might seem like an added expense, it's often cheaper than paying a professional welder or buying the tools and materials needed to fabricate custom mounts.

- Precise Alignment: Good quality adapter plates are designed to ensure proper engine alignment within the chassis. This is crucial for drivetrain longevity and preventing vibrations. Misalignment can lead to premature wear on your transmission, driveshaft, and other components.

- Safety: Professionally manufactured adapter plates are engineered to withstand the stresses of engine torque. Homemade mounts might not be as strong or reliable.

SBC Motor Mount Adapter Plate Specifications: What to Look For

Choosing the right adapter plates is crucial. Here's what you need to consider:

1. SBC Engine Type

First and foremost, you need to identify which type of SBC you're working with. While many SBCs share the same basic block dimensions, the position and style of the motor mount bosses can vary. Common SBC engine types include:

- Gen 1 SBC (1955-1995): This is the classic SBC design, found in countless vehicles. However, even within the Gen 1 family, there can be variations in the motor mount boss locations.

- LT1/LT4 (1992-1997): These are reverse-cooled SBCs that use a different block design, including different motor mount boss locations.

- Vortec SBC (1996-2003): Vortec heads offer improved flow, but the block is still based on the Gen 1 design. Ensure the adapter plate you choose is compatible with the Vortec block you have.

- LS-Based Engines (LS1, LS2, LS3, etc.): While technically not a traditional SBC, the LS family shares a similar architecture and is a common swap choice. LS engines require completely different adapter plates than traditional SBCs. If you are working with an LS engine, these adapter plates won't work.

Always double-check the adapter plate's compatibility with your specific SBC engine!

2. Vehicle Frame Mount Type

Next, you need to determine the type of motor mounts currently installed in your vehicle's frame. Common types include:

- Clamshell Mounts: These are common on older trucks and cars. They typically consist of two pieces that "clamp" around the engine mount.

- "Biscuit" Mounts: These are round, rubber mounts that are bolted to the frame and the engine.

- Saddle Mounts: These are similar to clamshell mounts, but they feature a saddle-shaped bracket that supports the engine mount.

The adapter plate needs to be designed to bolt directly to your existing frame mounts. Measure the distance between the bolt holes on your frame mounts to ensure a proper fit. Many adapter plates are designed to be universal, fitting several different frame mount types, but it's crucial to verify compatibility.

3. Material and Construction

Look for adapter plates made from high-quality steel or aluminum. Steel is generally stronger and more durable, making it a good choice for high-performance applications. Aluminum is lighter and corrosion-resistant, which is beneficial in certain environments.

The thickness of the adapter plate is also important. Thicker plates are generally stronger and less prone to bending or flexing under load. A good quality adapter plate should be at least 1/4 inch thick, and preferably thicker for high-horsepower applications.

4. Offset and Position

Adapter plates can sometimes offset the engine slightly forward or backward. This can be necessary to provide clearance for the exhaust manifolds, steering components, or other parts. Pay close attention to the adapter plate's offset and ensure it won't cause any interference issues.

Some adapter plates also allow you to adjust the engine's height. This can be useful for achieving proper hood clearance or improving the engine's center of gravity.

5. Hardware

Make sure the adapter plate kit includes all the necessary hardware, such as bolts, washers, and nuts. Use Grade 8 hardware for maximum strength and reliability. If the kit doesn't include hardware, you'll need to purchase it separately. Ensure the bolts are the correct length and thread pitch for your engine and frame mounts.

Installation Tips and Considerations

Here are some helpful tips for installing SBC motor mount adapter plates:

- Safety First: Always disconnect the battery before working on your vehicle. Use jack stands to safely support the vehicle.

- Cleanliness is Key: Clean the engine block and frame mount surfaces thoroughly before installing the adapter plates. This will ensure a good, secure connection.

- Torque Specifications: Follow the manufacturer's torque specifications when tightening the bolts. Overtightening can damage the adapter plates or engine block. Use a torque wrench for accuracy.

- Pilot the Engine: Use an engine hoist to carefully lower the engine into the chassis. Take your time and ensure the adapter plates align properly with the frame mounts.

- Check for Clearance: Once the engine is installed, check for clearance between the engine and other components, such as the exhaust manifolds, steering components, and firewall. Make any necessary adjustments.

- Double-Check: After a short test drive, double-check all the bolts to ensure they are still tight.

Tools Needed

You'll need the following tools for installing SBC motor mount adapter plates:

- Socket set

- Wrench set

- Torque wrench

- Engine hoist

- Jack and jack stands

- Penetrating oil

- Shop rags

- Safety glasses

- Gloves

Approximate Repair Costs

The cost of SBC motor mount adapter plates can vary depending on the manufacturer, material, and design. Expect to pay anywhere from $50 to $200 for a good quality set. The cost of labor for installing the adapter plates will depend on the complexity of the swap and the hourly rate of the mechanic. A simple installation might take a few hours, while a more complex swap could take several days. Budget accordingly.

Pro Tip: Before purchasing adapter plates, take accurate measurements of your engine block and frame mounts. This will help you choose the correct adapter plates and avoid any fitment issues. Take pictures and notes, especially if you're working on a less common swap.

Remember to always prioritize safety and consult a professional mechanic if you're unsure about any aspect of the installation. With the right adapter plates and a little patience, you'll have your SBC engine installed in no time!