Subframe Spacer Installation And Geometry Correction

So, you're looking to install subframe spacers and correct your car's geometry, huh? Excellent choice. This is a modification that can significantly improve handling and ride quality, especially on lowered vehicles. It might seem daunting, but with a good understanding of the process and the right tools, it's definitely achievable for the experienced DIYer. Let's dive in.

Understanding Subframe Spacers and Geometry Correction

First things first, let's define what we're talking about. A subframe (also known as a cradle or suspension crossmember) is a structural component of your vehicle that supports the engine, transmission, and/or suspension components. It's essentially a secondary frame that bolts to the main chassis. Lowering your car, while visually appealing, can negatively impact the suspension geometry. Specifically, it changes the instant center and roll center, leading to increased body roll, bump steer, and reduced traction.

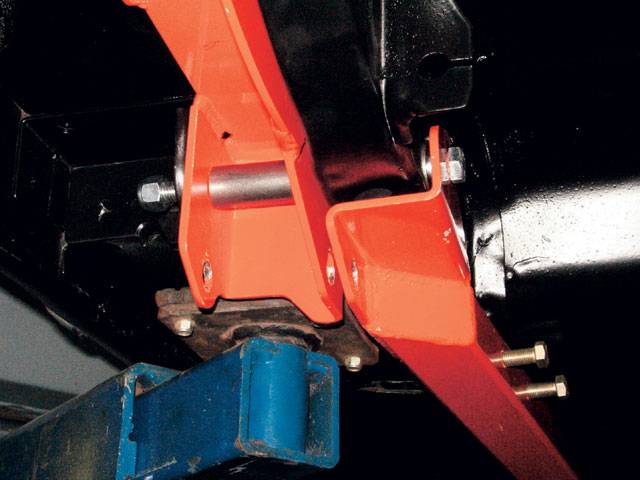

Subframe spacers are precisely machined pieces of metal (usually aluminum or steel) that are installed between the subframe and the chassis. Their primary purpose is to lower the subframe relative to the chassis. This seemingly simple change has a profound impact on suspension geometry. By lowering the subframe, we can correct the suspension geometry back closer to its factory specifications, or even optimize it for specific performance goals.

Think of it this way: Imagine a lever. The shorter the lever, the less leverage you have. Lowering your car changes the length and angle of your suspension arms, effectively reducing their leverage. Spacers help restore that leverage, leading to better handling. Common issues addressed by subframe spacers include:

- Bump Steer: This is when the steering wheel turns slightly as the suspension compresses and decompresses. It's caused by changes in the toe angle during suspension travel.

- Roll Center Migration: The roll center is the point around which the car rolls during cornering. Lowering the car can cause the roll center to move excessively, leading to increased body roll and reduced grip.

- Reduced Anti-Squat/Anti-Dive: Lowering alters the anti-squat and anti-dive characteristics of the suspension, which can affect acceleration and braking performance.

Geometry correction aims to mitigate these negative effects by restoring the optimal angles and relationships within the suspension system. Subframe spacers are one piece of the puzzle, often used in conjunction with other modifications like adjustable control arms and ball joints.

Tools and Materials You'll Need

Before you start tearing things apart, make sure you have all the necessary tools and materials. Safety is paramount, so don't skimp on quality.

- Jack and Jack Stands: A good quality floor jack and sturdy jack stands are essential. Never work under a car supported only by a jack.

- Wheel Chocks: For added safety, chock the rear wheels.

- Socket Set and Wrenches: You'll need a comprehensive set of metric sockets and wrenches, including deep sockets and extensions.

- Torque Wrench: Absolutely critical for tightening bolts to the correct specifications. Refer to your vehicle's service manual for torque values.

- Impact Wrench (Optional): An impact wrench can make loosening stubborn bolts much easier.

- Penetrating Oil: Spray all bolts with penetrating oil a day or two before starting the project to help loosen them.

- Pry Bar: For gently persuading the subframe into alignment.

- Alignment Tools (Optional but Recommended): Camber gauge, toe plates, or a laser alignment system will help you accurately dial in your alignment after the installation.

- Subframe Spacers: Choose a reputable brand and ensure they are compatible with your vehicle.

- New Subframe Bolts (Highly Recommended): It's best practice to replace the subframe bolts with new ones, especially if they are torque-to-yield (TTY) bolts. These bolts are designed to stretch when tightened and should not be reused.

- Threadlocker: Use threadlocker (like Loctite) on the subframe bolts.

- Wheel Alignment Appointment: Even if you have alignment tools, it's highly recommended to get a professional wheel alignment after installing subframe spacers.

- Gloves and Safety Glasses: Protect your hands and eyes.

- Service Manual: Your vehicle's service manual is an invaluable resource for torque specifications and other important information.

Installation Procedure

Now, let's get to the actual installation. Remember to consult your vehicle's service manual for specific instructions and torque specifications, as procedures can vary slightly depending on the make and model.

- Preparation: Park your car on a level surface. Engage the parking brake and chock the rear wheels. Loosen the lug nuts on the front wheels.

- Lifting the Vehicle: Use the floor jack to lift the front of the car and securely support it with jack stands placed under the designated jacking points. Ensure the jack stands are properly seated and stable. Remove the front wheels.

- Locating the Subframe Bolts: Identify the subframe bolts that secure the subframe to the chassis. These bolts are typically large and located in easily accessible areas. There are typically 4 bolts to loosen.

- Loosening the Subframe Bolts: Using your socket wrench (or impact wrench), carefully loosen the subframe bolts. Do not remove them completely at this stage. Loosen them gradually in a criss-cross pattern to avoid binding or stressing the subframe. Leave a few threads engaged on each bolt.

- Supporting the Subframe: Use the floor jack (or a transmission jack) to support the subframe. This will prevent it from dropping suddenly when you remove the bolts. Position the jack under the subframe's center point for even support.

- Removing the Subframe Bolts: Now, carefully remove the subframe bolts one at a time. As you remove each bolt, ensure the subframe is securely supported by the jack.

- Installing the Spacers: With the subframe supported, carefully install the subframe spacers between the subframe and the chassis. Ensure the spacers are properly aligned and seated. Note that some spacers may have a specific orientation.

- Installing New Subframe Bolts: Install the new subframe bolts (if applicable) through the spacers and into the chassis. Apply threadlocker to the threads of the bolts.

- Tightening the Subframe Bolts: Carefully tighten the subframe bolts to the torque specifications specified in your vehicle's service manual. Tighten them in a criss-cross pattern and in multiple stages to ensure even clamping pressure. If using TTY bolts, follow the specified tightening procedure (e.g., torque to a specific value, then turn a certain number of degrees).

- Lowering the Subframe: Slowly lower the subframe using the jack until it is fully supported by the chassis.

- Reinstalling the Wheels: Reinstall the front wheels and tighten the lug nuts to the specified torque.

- Lowering the Vehicle: Carefully lower the vehicle to the ground.

- Final Torque Check: Once the car is on the ground, re-torque the lug nuts and subframe bolts.

- Wheel Alignment: Schedule a professional wheel alignment as soon as possible. This is crucial for ensuring proper handling and tire wear.

- Test Drive: Take the car for a test drive and listen for any unusual noises or vibrations. Pay attention to the handling and steering feel.

Troubleshooting

Even with careful planning, you might encounter some issues during the installation process. Here are a few common problems and their solutions:

- Stuck Bolts: If the subframe bolts are seized, try applying more penetrating oil and using an impact wrench. You can also try heating the area around the bolt with a heat gun (carefully, to avoid damaging surrounding components). If all else fails, you may need to use a bolt extractor.

- Misaligned Subframe: After installing the spacers, the subframe may not line up perfectly with the bolt holes. Use a pry bar to gently persuade the subframe into alignment. Be careful not to damage any components.

- Vibrations: If you experience excessive vibrations after installing the spacers, double-check that the subframe bolts are properly torqued and that the spacers are correctly seated.

Important Considerations

Safety First: Always prioritize safety when working on your car. Use jack stands, wear safety glasses, and follow proper procedures.

Torque Specifications: Using the correct torque specifications is essential for ensuring the integrity of the suspension system. Refer to your vehicle's service manual.

Wheel Alignment: A proper wheel alignment is crucial after installing subframe spacers. This will ensure proper handling, tire wear, and overall safety.

Inspect Regularly: After the installation, periodically inspect the subframe bolts and spacers for any signs of loosening or damage.

Installing subframe spacers and correcting your car's geometry can be a rewarding project that improves handling and ride quality. By understanding the principles involved, following the proper procedures, and using the right tools, you can achieve professional-level results. Remember to take your time, be careful, and always prioritize safety. Good luck!