Suspension Build Component Selection And Geometry Setup

So, you're thinking about upgrading or rebuilding your suspension? That's fantastic! A well-sorted suspension can dramatically improve your vehicle's handling, ride comfort, and overall driving experience. But navigating the world of suspension components and geometry setup can feel like a daunting task. Don't worry, you're not alone! Many enthusiasts and even experienced drivers get a little overwhelmed. This article will break down the key areas, helping you make informed decisions and avoid common pitfalls.

Understanding the Core Issues

Before diving into specific components, let's address some common problems that often lead to suspension work:

- Poor Handling: Your car feels unstable in corners, exhibits excessive body roll, or doesn't respond predictably to steering inputs. This could be due to worn shocks, inadequate springs, or incorrect alignment.

- Rough Ride Quality: Bumps and imperfections in the road are transmitted harshly to the cabin. This often points to tired shocks/struts or overly stiff springs.

- Uneven Tire Wear: If your tires are wearing unevenly (e.g., excessive wear on the inside or outside edges), it's almost always a suspension issue, specifically an alignment problem, but worn components can also contribute.

- Sagging or Leaning: A vehicle that sags significantly on one side or sits lower than normal indicates worn springs, potentially a broken spring, or a failing air suspension component (if equipped).

- Clunking or Squeaking Noises: These sounds often signal worn bushings, ball joints, or other suspension components that are allowing excessive movement.

Accurately diagnosing the underlying problem is crucial. A thorough visual inspection, looking for worn parts, leaks, and damage, is the first step. A test drive, paying attention to how the vehicle handles and feels, can also provide valuable clues.

Component Selection: Choosing the Right Parts

Once you've identified the problem, it's time to select the appropriate replacement or upgrade components. Here's a breakdown of some key considerations:

Shocks and Struts:

These control the damping (oscillation) of the suspension. They're responsible for keeping the tires in contact with the road and preventing excessive bouncing. When choosing shocks or struts, consider your driving style and the intended use of your vehicle.

- OEM Replacements: These are designed to match the original equipment specifications and are a good choice for maintaining the factory ride quality and handling. Expect to pay around $100-$300 per shock/strut, plus labor.

- Performance Shocks/Struts: These offer improved damping characteristics, resulting in better handling and control. Options range from mild upgrades for improved street performance to adjustable coilovers for track use. Prices can range from $300-$2000+ per corner depending on the features and adjustability.

Tip: When replacing shocks or struts, always replace them in pairs (both front or both rear) to ensure balanced handling.

Springs:

Springs support the weight of the vehicle and determine its ride height. They also play a role in handling characteristics. Lowering springs can improve handling by lowering the center of gravity, but they can also negatively impact ride quality if not paired with appropriate shocks/struts.

- OEM Replacements: If your springs are sagging or broken, replacing them with OEM springs will restore the factory ride height and handling.

- Lowering Springs: These springs are shorter and stiffer than OEM springs, lowering the vehicle's ride height. They often require shorter shocks/struts to maintain proper suspension travel. Expect to pay $200-$500 for a set of lowering springs.

- Coilovers: These combine a shock absorber and a spring into a single unit. They offer adjustable ride height and damping, allowing for precise tuning of the suspension. Coilovers are the most expensive option, typically ranging from $800-$3000+ per set.

Bushings:

Bushings are rubber or polyurethane components that isolate suspension components from the chassis. They absorb vibrations and reduce noise. Worn bushings can lead to sloppy handling, clunking noises, and increased tire wear.

- Rubber Bushings: These are the factory-installed bushings and offer a good balance of comfort and durability.

- Polyurethane Bushings: These bushings are stiffer than rubber bushings, providing improved handling and durability. However, they can also transmit more noise and vibration to the cabin. Expect to pay $5-$50 per bushing, depending on the location and material.

Tip: Replacing bushings can be a time-consuming process, requiring specialized tools and techniques. If you're not comfortable doing it yourself, it's best to have a professional mechanic handle this task.

Ball Joints and Tie Rod Ends:

These components connect the suspension to the steering system. Worn ball joints or tie rod ends can lead to loose steering, excessive play, and uneven tire wear. They're critical for safe and precise steering.

- OEM Replacements: These are the best choice for maintaining the factory steering feel and durability.

- Upgraded Ball Joints/Tie Rod Ends: Some manufacturers offer upgraded ball joints and tie rod ends with improved strength and durability, particularly beneficial for vehicles that are driven hard or used for off-roading. Expect to pay $50-$200 per ball joint or tie rod end, plus labor.

Geometry Setup: Getting the Alignment Right

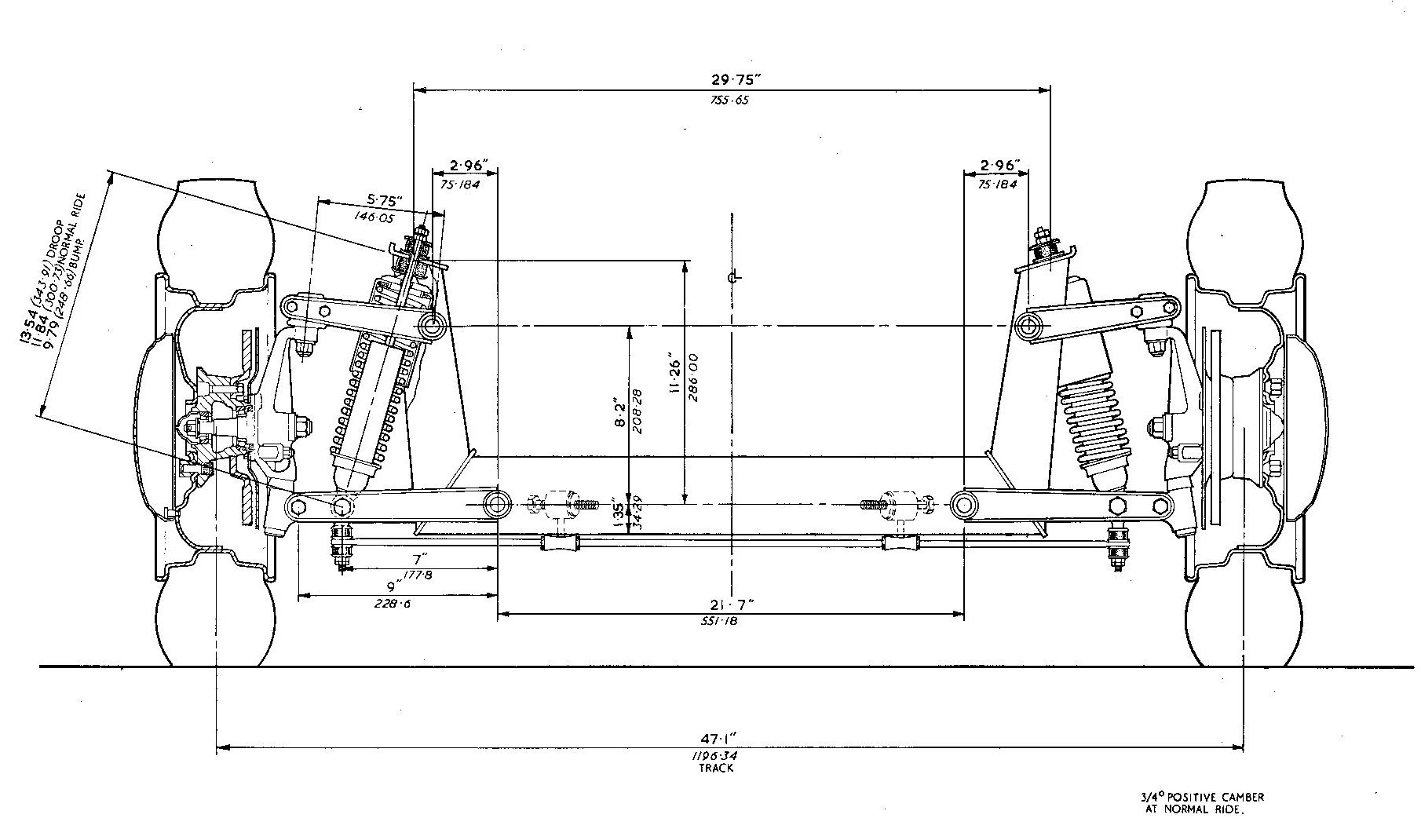

Even with the best components, your suspension won't perform properly if the geometry is not correctly set. This is where alignment comes in. Alignment involves adjusting the angles of the wheels to ensure they are properly oriented relative to the vehicle's chassis. The three main alignment angles are:

- Camber: The angle of the wheel relative to the vertical axis. Negative camber (top of the wheel tilted inward) is often used to improve cornering grip.

- Caster: The angle of the steering axis relative to the vertical axis. Positive caster (steering axis tilted rearward) improves straight-line stability and steering feel.

- Toe: The angle of the wheel relative to the vehicle's centerline. Toe-in (wheels pointed slightly inward) or toe-out (wheels pointed slightly outward) can affect handling and tire wear.

After any suspension work, it's essential to have a professional alignment performed. This will ensure that your tires wear evenly, your vehicle handles properly, and your steering is precise. The cost of an alignment typically ranges from $80-$200.

Important: When having an alignment performed, be sure to provide the alignment technician with the factory specifications or any specific alignment settings recommended for your vehicle and driving style.

Tools and Considerations

Depending on the scope of your suspension project, you may need a variety of tools, including:

- Jack and Jack Stands: To safely lift and support the vehicle.

- Wrenches and Sockets: In various sizes to remove and install suspension components.

- Torque Wrench: To ensure that fasteners are tightened to the correct specifications.

- Ball Joint Separator/Pickle Fork: To separate ball joints and tie rod ends.

- Spring Compressor: To safely compress coil springs for removal and installation (use with extreme caution!).

- Alignment Tools: While a full alignment requires specialized equipment, basic tools like a camber gauge can be helpful for initial adjustments.

Safety is paramount when working on suspension components. Always use jack stands to support the vehicle, wear safety glasses, and follow all safety precautions outlined in the vehicle's repair manual. If you're not comfortable working on your suspension, it's best to leave it to a qualified mechanic.

Estimated Costs

Here's a rough estimate of the costs associated with common suspension repairs and upgrades:

- Shock/Strut Replacement (OEM): $400-$1000 per axle (parts and labor)

- Spring Replacement (OEM): $300-$800 per axle (parts and labor)

- Lowering Spring Installation: $500-$1200 (parts and labor)

- Coilover Installation: $800-$2000+ (parts and labor)

- Bushing Replacement: Varies widely depending on the location and complexity, but typically $100-$500 per corner.

- Ball Joint/Tie Rod End Replacement: $200-$500 per component (parts and labor)

- Wheel Alignment: $80-$200

These are just estimates, and the actual cost may vary depending on the vehicle, the specific components used, and the labor rates in your area. It's always a good idea to get quotes from multiple shops before proceeding with any work.

Building a well-sorted suspension takes knowledge and careful planning. By understanding the core issues, selecting the right components, and paying attention to geometry setup, you can transform your vehicle's handling and driving experience. Don't hesitate to consult with a qualified mechanic or suspension specialist if you have any questions or need assistance.