Technical Analysis Of Steering Angle Modification Kits For The S13 Chassis

Alright, let's dive into the world of steering angle modification kits for the Nissan S13 chassis. Whether you're chasing serious angle for drifting or just want a sharper feeling street car, understanding the technical details of these kits is crucial for a successful installation and optimal performance. This isn't just slapping on some shiny parts; it's about geometry, forces, and how they all interact.

Understanding the S13 Steering System Basics

Before we get into modifying, let's quickly recap the stock S13 steering system. We're dealing with a rack and pinion system. The steering wheel rotates, turning the pinion gear which moves the rack laterally. Tie rods connect to the rack ends and translate that linear motion into rotational movement at the steering knuckles (also known as spindles). This rotation pivots the wheels for steering.

The stock S13 has a relatively limited steering angle. This can be a hindrance for drifting, where you need to quickly counter-steer and maintain a large slip angle. That's where these modification kits come into play.

What Steering Angle Kits Change

Steering angle kits primarily focus on modifying the geometry and components within the steering system to achieve a greater range of wheel movement. Here are the key areas they address:

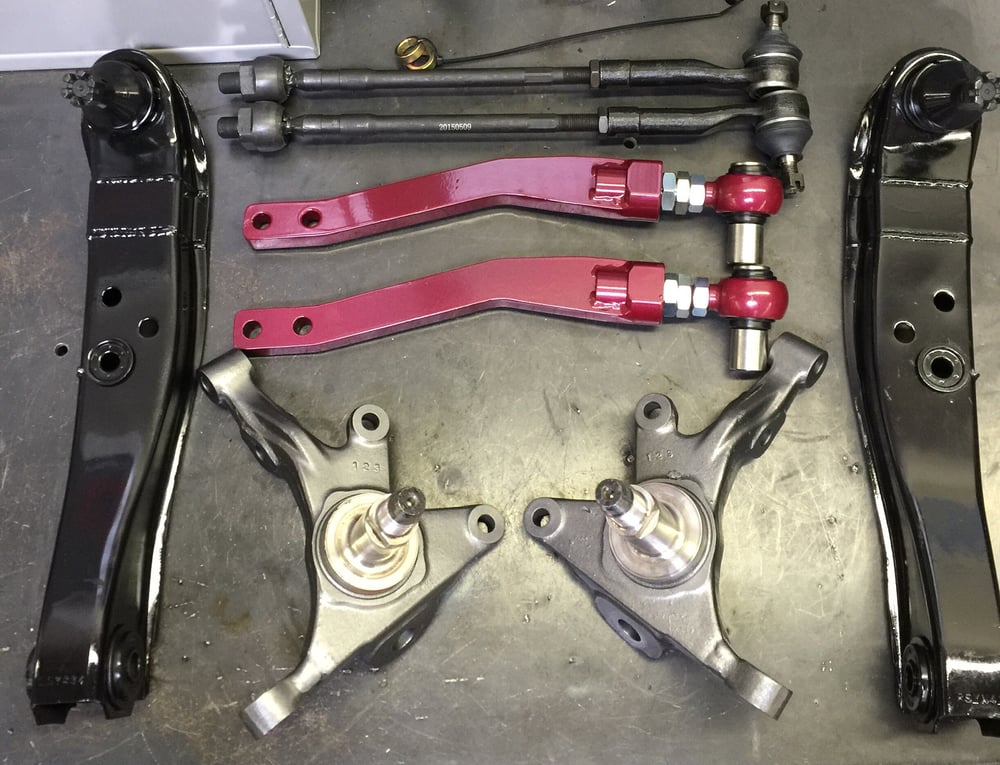

1. Modified Steering Knuckles (Spindles)

The most common component in a steering angle kit is a modified knuckle. The steering arm (the point where the tie rod connects) is typically shortened and/or relocated. Shortening the steering arm effectively quickens the steering ratio, meaning less steering wheel input is needed for a given wheel angle. However, it also increases the force required to steer, which we'll address later.

The relocation of the steering arm is crucial for increasing angle. By moving it further outboard (away from the center of the car), you increase the leverage and allow for a greater range of motion before the tie rod binds or reaches its physical limit. Some kits also adjust the kingpin inclination (KPI) and caster angle via the knuckle design. KPI influences steering feel and self-centering, while caster affects straight-line stability and camber gain during turns.

2. Extended Tie Rods and Ends

To accommodate the increased range of motion provided by the modified knuckles, you'll need longer tie rods. These are usually fabricated from high-strength steel or aluminum and often come with adjustable ends. The adjustable ends allow you to fine-tune the toe settings after installation, as changing the steering geometry inevitably affects toe.

It's critical to use high-quality tie rod ends, preferably rod ends (heim joints) instead of rubber bushings. Rod ends offer significantly less deflection under load, providing a more direct and responsive steering feel. However, they also transmit more road noise and vibration into the cabin and require periodic maintenance and inspection.

3. Rack Spacers

Rack spacers are installed between the steering rack and the inner tie rod ends. They effectively extend the rack's travel, allowing for more wheel angle before the rack reaches its internal stops. This is often used in conjunction with modified knuckles to maximize steering angle. However, exceeding the rack's travel limits can damage the rack and pinion mechanism, so proper installation and careful setup are essential.

4. Offset Rack Bushings

These bushings reposition the steering rack slightly. This can improve bump steer characteristics, which we'll discuss shortly. They can also sometimes be used to provide slightly more clearance for other components in the engine bay when running extreme steering angles.

Technical Considerations and Potential Drawbacks

While steering angle kits offer significant benefits, it's important to be aware of the potential drawbacks and technical considerations:

1. Bump Steer

Bump steer occurs when the wheels steer themselves slightly as the suspension moves up and down. This happens when the tie rod angle relative to the lower control arm changes during suspension travel. Modifying the steering geometry can exacerbate bump steer, leading to unpredictable handling. This is why proper alignment and potentially the use of offset rack bushings are crucial. Ideally, you want to minimize bump steer, ensuring the tie rod and lower control arm arcs are as parallel as possible throughout their range of motion. A bump steer gauge is often used to measure and correct this issue.

2. Ackermann Angle

Ackermann angle is the difference in angle between the inner and outer front wheels during a turn. It's designed to ensure that each wheel follows its optimal turning radius, preventing tire scrub and improving grip. Modifying the steering knuckles can alter the Ackermann angle, potentially leading to understeer or oversteer characteristics. Some kits offer adjustable Ackermann correction to fine-tune the handling balance.

3. Steering Effort

As mentioned earlier, shortening the steering arm increases the steering ratio, but it also increases the steering effort. This means you'll need to apply more force to the steering wheel to achieve the same wheel angle. This can be tiring during extended periods of driving, especially at low speeds. Power steering systems can often compensate, but upgrading to a higher-flowing power steering pump or even an electric power steering (EPS) system might be necessary for extreme angles.

4. Clearance Issues

Increasing steering angle often leads to clearance issues. The wheels and tires may rub against the frame rails, fender liners, or other suspension components. This may require modifications such as fender rolling, clearancing the frame rails, or using wheel spacers. Careful measurement and planning are essential to avoid these problems.

5. Increased Load on Components

Greater steering angles place increased stress on all steering and suspension components, including the tie rods, ball joints, wheel bearings, and even the steering rack itself. Using high-quality components and performing regular maintenance are crucial to prevent premature wear and failure.

6. Lock-to-Lock Speed

While you gain more angle, be aware that the lock-to-lock speed (the time it takes to turn the steering wheel from one extreme to the other) can be drastically increased with a modified ratio. This takes some getting used to and quick hands can make or break a drift run.

Installation Tips and Considerations

Here are a few tips to keep in mind when installing a steering angle kit on your S13:

- Thoroughly research different kits: Not all kits are created equal. Consider your specific needs and budget when choosing a kit. Read reviews, compare specifications, and talk to other S13 owners who have installed similar kits.

- Pay attention to instructions: Follow the manufacturer's instructions carefully. Improper installation can lead to serious safety issues.

- Use a torque wrench: Torque all fasteners to the specified values. Over- or under-tightening can damage components or cause them to fail.

- Get a professional alignment: After installing the kit, take your car to a reputable alignment shop. A proper alignment is essential for optimal handling and tire wear. Make sure they are familiar with modified suspension systems and can properly set the toe, camber, and caster angles.

- Inspect regularly: Periodically inspect the steering and suspension components for wear or damage. Replace any worn or damaged parts immediately. Pay close attention to tie rod ends and ball joints.

- Consider bump steer correction: Evaluate bump steer after installation. If necessary, use offset rack bushings or adjustable tie rod ends to minimize bump steer.

Conclusion

Steering angle modification kits can significantly enhance the handling and driftability of your S13. However, it's crucial to understand the technical implications and potential drawbacks before installing one. By carefully considering your needs, choosing a high-quality kit, and following proper installation procedures, you can achieve a significant improvement in steering performance without compromising safety or reliability. Remember that this is just one piece of the puzzle; a well-sorted chassis includes balanced suspension, proper weight distribution, and a skilled driver behind the wheel.