Technical Guide To Twin-turbocharging A Nissan 240sx Engine

So, you're thinking about twin-turbocharging your Nissan 240SX? That's a bold move, but one that can unlock some serious horsepower. While the 240SX is known for its lightweight chassis and drift-friendly handling, its stock engine often leaves enthusiasts wanting more. Twin turbos can provide a significant boost in power and torque, transforming your car into a real performance machine. However, it's not a project for the faint of heart. This guide will walk you through some common hurdles and potential solutions you might encounter during your twin-turbo conversion.

Common Problems and Solutions During a Twin-Turbo 240SX Build

Before diving in, let's be realistic. A twin-turbo conversion is complex and involves a lot more than just slapping on two turbos. You'll be dealing with everything from exhaust manifolds to fuel management, and potential fitment issues. Here are some of the most frequent problems, along with troubleshooting tips:

1. Fitment Issues and Clearance

This is probably the biggest headache for most 240SX owners. The engine bay isn't exactly spacious, and cramming two turbos in there, along with all the associated piping, can be a real challenge.

Problem: Turbos physically don't fit. They interfere with the chassis, steering components, or other engine accessories.

Solutions:

- Careful Turbo Selection: Choose appropriately sized turbos. Smaller turbos might be easier to package, even if they don't offer the absolute maximum power potential. Research is key here. Forums and build logs can provide valuable insights into what others have successfully used. Garrett GT25s or similar-sized units are often a good starting point.

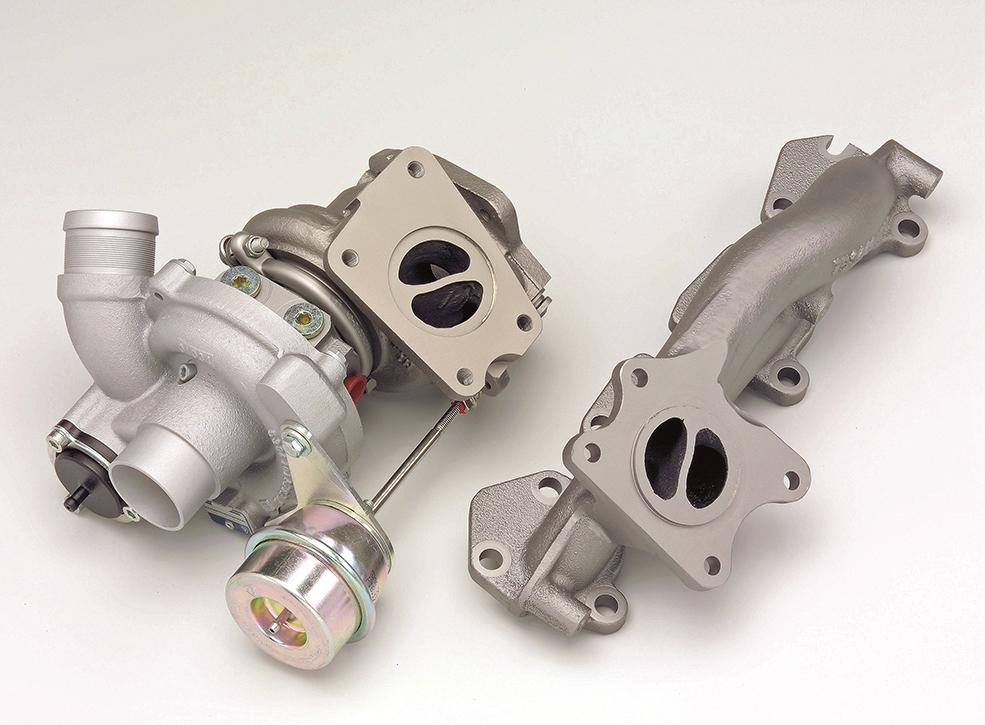

- Custom Manifolds: Off-the-shelf manifolds *might* work, but often require modifications. Custom manifolds, while more expensive, allow you to precisely position the turbos for optimal clearance. This is often the best solution for minimizing fitment issues. Expect to pay anywhere from $800 to $2000+ for custom manifolds, depending on the complexity and materials.

- Heat Shielding and Wrapping: Even if you achieve adequate clearance, heat from the turbos can still cause problems. Wrap your manifolds and downpipes with heat wrap to reduce radiant heat and protect surrounding components. Heat shields can also be fabricated or purchased to further isolate heat-sensitive areas.

- Minor Chassis Modifications: In some extreme cases, minor clearancing of the chassis might be necessary. This should be a last resort and done with extreme care to avoid compromising structural integrity. Consult with a professional fabricator if you're considering this.

2. Fueling Problems

More air requires more fuel. Your stock fuel system simply won't be able to keep up with the demands of a twin-turbo setup.

Problem: Fuel starvation leading to lean conditions, potentially causing engine damage.

Solutions:

- Upgraded Fuel Pump: A high-flow fuel pump is essential. Walbro 255lph pumps are a common and reliable choice for moderate power goals. For higher horsepower, you might need dual pumps or a larger in-tank or external pump. Expect to spend around $100-$300 on a good fuel pump.

- Larger Fuel Injectors: Your stock injectors will be maxed out quickly. Upgrade to larger injectors sized appropriately for your desired power level. Bosch EV14 injectors are a popular choice for their performance and reliability. Consult with a tuner or fuel injector calculator to determine the correct size for your setup. A set of good injectors can cost $400-$800.

- Fuel Pressure Regulator: An adjustable fuel pressure regulator (FPR) allows you to fine-tune your fuel pressure and ensure consistent delivery. This is especially important with larger injectors. A quality FPR will run around $100-$200.

- Fuel Rail Upgrade: While not always necessary, an upgraded fuel rail can improve fuel flow and distribution, especially at higher power levels. Expect to pay $200-$400.

3. Engine Management and Tuning

The ECU needs to know what's going on with the turbos and adjust fuel and timing accordingly. The stock ECU simply isn't designed for this.

Problem: Engine running poorly, misfires, detonation, and potential engine damage due to improper fuel and timing.

Solutions:

- Standalone ECU: A standalone ECU, such as a Haltech, AEM, or Link ECU, offers complete control over your engine's parameters. This is the best solution for a twin-turbo setup, as it allows for precise tuning and advanced features like boost control and data logging. Standalone ECUs can range from $1000 to $3000+ depending on features and complexity.

- Piggyback ECU: A piggyback ECU intercepts and modifies the signals from the stock ECU. While less powerful than a standalone, it can be a more affordable option for simpler setups. However, they can be difficult to tune and may not offer the same level of control. A piggyback ECU might cost $300-$800.

- Professional Tuning: Regardless of which ECU you choose, professional tuning is essential. A skilled tuner will be able to optimize your engine's performance and ensure its reliability. Tuning can cost anywhere from $500 to $1500+ depending on the complexity of the setup and the tuner's experience.

4. Intercooling

Turbocharging creates heat. Hot intake air reduces power and increases the risk of detonation. You need an effective intercooling system.

Problem: High intake air temperatures (IATs) leading to reduced power and potential engine damage.

Solutions:

- Front Mount Intercooler (FMIC): An FMIC is the most common choice for 240SXs. It provides excellent cooling efficiency by positioning the intercooler in front of the radiator. You'll need to modify the front bumper or bumper support to accommodate the intercooler. A good FMIC kit can cost $300-$800.

- Water-to-Air Intercooler: Water-to-air intercoolers are more compact than FMICs and can be a good option if space is limited. They use a water-cooled core to cool the intake air. However, they require a separate water pump and reservoir, adding to the complexity and cost. Expect to pay $500-$1000+ for a complete water-to-air intercooler setup.

- Proper Piping: Use high-quality intercooler piping that is appropriately sized for your turbos and engine. Silicone couplers and T-bolt clamps are essential for preventing leaks.

5. Oil and Water Lines

Turbos need a reliable supply of oil for lubrication and, in some cases, water for cooling.

Problem: Oil starvation or leaks, leading to turbo failure. Water leaks causing cooling system issues.

Solutions:

- Proper Sizing and Routing: Use correctly sized oil and water lines that are specifically designed for turbochargers. Avoid sharp bends or kinks that can restrict flow. Stainless steel braided lines are recommended for their durability and resistance to heat.

- Quality Fittings: Use high-quality AN fittings to ensure a leak-free connection. Teflon tape or liquid sealant can be used to seal the threads.

- Oil Restrictor: Some turbos require an oil restrictor to prevent over-oiling, which can lead to smoking. Consult the turbo manufacturer's specifications.

- Proper Drain: Ensure the oil drain line is large enough and flows downhill to the oil pan. A restricted drain can cause oil to back up in the turbo, leading to seal failure.

6. Exhaust System

The stock exhaust system is far too restrictive for a twin-turbo engine.

Problem: Exhaust backpressure hindering turbo performance and potentially damaging the engine.

Solutions:

- Downpipes: Fabricate or purchase custom downpipes that connect the turbos to the rest of the exhaust system. Downpipes should be as large as possible (3" is a good starting point) and should have smooth bends to minimize backpressure.

- Cat-Back Exhaust: A high-flow cat-back exhaust system will further reduce backpressure and improve exhaust flow. A 3" system is generally recommended for a twin-turbo 240SX.

- Wastegates: External wastegates are highly recommended for precise boost control. They vent excess exhaust gases to prevent overboosting. Ensure the wastegates are properly sized for your turbos and power goals.

Essential Tools and Equipment

Here's a list of tools you'll likely need for a twin-turbo conversion:

- Basic Hand Tools: Wrenches, sockets, screwdrivers, pliers, etc.

- Torque Wrench: Essential for tightening bolts to the correct specifications.

- Cutting Tools: Angle grinder, reciprocating saw, or plasma cutter for modifying the chassis and fabricating brackets.

- Welding Equipment: MIG or TIG welder for fabricating manifolds, downpipes, and other components.

- Drill and Drill Bits: For drilling holes for mounting brackets and sensors.

- Fuel Pressure Gauge: To monitor fuel pressure.

- Boost Gauge: To monitor boost levels.

- Multimeter: For electrical troubleshooting.

- Laptop: For tuning the ECU.

Approximate Costs

A twin-turbo 240SX conversion can range from $5,000 to $15,000+, depending on the quality of the parts, the complexity of the build, and whether you do the work yourself or hire a professional.

Important Note: This guide provides general information and should not be considered a substitute for professional advice. Always consult with a qualified mechanic or tuner before undertaking a twin-turbo conversion. Safety is paramount. Wear appropriate safety gear when working on your car, and always disconnect the battery before working on the electrical system.

Good luck with your build! With careful planning and execution, you can transform your 240SX into a truly impressive machine.