Technical Overview Of The Nissan 240sx Rear Subframe And Differential Assembly

The Nissan 240SX, particularly the S13 and S14 generations, is a beloved car among drifting enthusiasts, tuners, and those who appreciate its rear-wheel-drive configuration. A crucial part of its appeal lies in its robust and relatively simple rear subframe and differential assembly. Understanding the technical overview of this assembly is essential for maintenance, upgrades, and diagnosing potential issues. This article will provide a detailed look at the components and their functions.

Rear Subframe: The Foundation

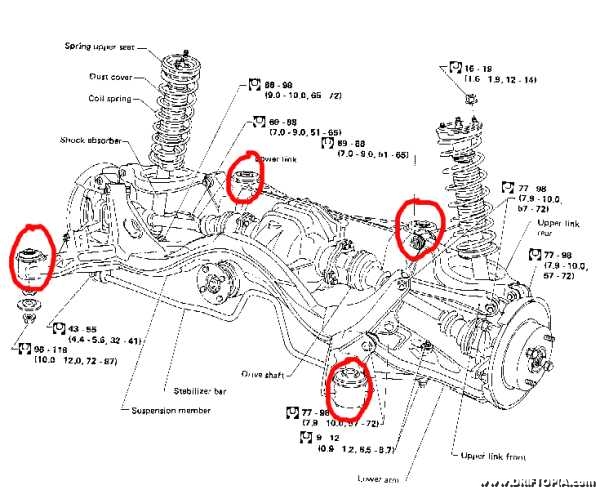

The rear subframe is a critical structural component that isolates the chassis from the rear suspension and differential. It's essentially a metal frame that bolts to the car's body and houses the suspension arms, differential, and often the rear anti-roll bar. Here's a breakdown of its key aspects:

Construction and Materials

The 240SX rear subframe is typically constructed from stamped and welded steel. This provides a balance between strength, weight, and cost-effectiveness. The steel is usually coated to resist corrosion, though rust can still be a problem, especially in areas with harsh winters.

Mounting Points

The subframe attaches to the chassis at multiple points, usually four. These mounting points are crucial because they affect the car's handling and NVH (Noise, Vibration, and Harshness) characteristics. Soft rubber bushings are used at these mounting points to dampen vibrations and road noise. However, these bushings can degrade over time, leading to sloppy handling and increased noise levels. Many aftermarket options exist, from stiffer polyurethane bushings to solid aluminum mounts, each offering a different trade-off between performance and comfort.

Suspension Arm Attachment Points

The rear suspension arms (lower control arms, upper control arms, and toe arms) all connect to the subframe. The location and design of these attachment points greatly influence the car's suspension geometry and handling characteristics. The 240SX allows for some adjustability in these areas, which is one reason why it's so popular for drifting and track use. Aftermarket suspension arms often offer even greater adjustability, allowing for precise fine-tuning of camber, caster, and toe angles.

Anti-Roll Bar (Sway Bar) Mounts

The rear anti-roll bar (also known as a sway bar or stabilizer bar) connects to the subframe, typically via brackets and bushings. The anti-roll bar helps to reduce body roll during cornering, improving handling and stability. Different aftermarket anti-roll bars offer varying stiffness levels, allowing drivers to tailor the car's handling balance to their preferences.

The Differential: Delivering Power to the Wheels

The differential is the heart of the rear drivetrain. Its primary function is to allow each rear wheel to rotate at a different speed, which is essential when cornering. Without a differential, the inside wheel would need to spin at the same rate as the outside wheel, causing wheel hop and making it difficult to turn.

Open Differential

The factory 240SX typically came equipped with an open differential. In an open differential, power is always sent to the wheel with the least resistance. This is fine for normal driving conditions, but it can be a significant disadvantage in performance applications. If one wheel loses traction (e.g., on ice or during hard acceleration), all the power will be sent to that wheel, and the other wheel will receive little to no power, resulting in wheel spin and reduced acceleration.

Limited-Slip Differential (LSD)

For performance applications, a limited-slip differential (LSD) is a significant upgrade. An LSD works by limiting the amount of difference in speed between the two rear wheels. This means that even if one wheel loses traction, the LSD will still transfer some power to the other wheel, helping to maintain traction and improve acceleration. There are several types of LSDs, including:

- Clutch-Type LSD: Uses a series of clutch plates to limit wheel slip. These are generally considered the strongest and most aggressive type of LSD, but they can also be noisy and require more maintenance.

- Torsen (Torque-Sensing) LSD: Uses gears to transfer torque to the wheel with more traction. Torsen LSDs are typically quieter and smoother than clutch-type LSDs, but they may not be as effective in situations where one wheel is completely off the ground.

- Viscous LSD: Uses a fluid-filled coupling to limit wheel slip. Viscous LSDs are generally the smoothest and quietest type of LSD, but they may not be as effective as clutch-type or Torsen LSDs in high-performance applications.

Differential Housing and Gearing

The differential is housed in a strong metal casing, typically made of cast iron or aluminum. The housing protects the internal components and provides mounting points for the axles and driveshaft. The differential also contains gears that reduce the engine's RPM to a suitable speed for the wheels. The gear ratio of the differential affects the car's acceleration and top speed. A lower gear ratio (e.g., 4.08) provides better acceleration, while a higher gear ratio (e.g., 3.54) provides a higher top speed. Swapping the differential gear ratio is a common modification for 240SX owners looking to improve their car's performance.

Axle Shafts

The axle shafts connect the differential to the rear wheels. They transmit the power from the differential to the wheels, allowing them to rotate. The 240SX uses independent rear suspension (IRS), which means that each wheel has its own axle shaft. These axle shafts are subject to considerable stress, especially in high-performance applications. Upgrading to stronger aftermarket axle shafts is often recommended for those who plan to drift or race their 240SX.

Maintenance and Upgrades

Proper maintenance is crucial for ensuring the longevity and performance of the 240SX rear subframe and differential assembly. Here are some key maintenance tasks:

- Regularly inspect the subframe for rust and damage. Repair any rust spots and address any structural damage immediately.

- Check the condition of the subframe bushings. Replace worn or damaged bushings with new ones, or upgrade to aftermarket polyurethane or solid bushings for improved performance.

- Change the differential fluid regularly. Use a high-quality gear oil that is appropriate for your driving conditions and differential type. The frequency of fluid changes will depend on your driving style and the type of differential you have.

- Inspect the axle shafts for wear and damage. Replace worn or damaged axle shafts as needed.

- Check the condition of the anti-roll bar bushings and end links. Replace worn or damaged bushings and end links with new ones, or upgrade to aftermarket components for improved performance.

There are also many aftermarket upgrades available for the 240SX rear subframe and differential assembly. Some popular upgrades include:

- Limited-slip differential (LSD): Provides improved traction and acceleration.

- Upgraded axle shafts: Increases strength and reliability, especially for high-performance applications.

- Aftermarket subframe bushings: Improves handling and reduces wheel hop.

- Adjustable suspension arms: Allows for precise fine-tuning of suspension geometry.

- Upgraded anti-roll bars: Reduces body roll and improves handling.

- Subframe collars: These stiffen the subframe mounting points, improving chassis rigidity.

- Differential brace: This adds strength and support to the differential housing, preventing it from cracking under stress.

Diagnosing Common Problems

Several common problems can occur with the 240SX rear subframe and differential assembly. Here are some symptoms and possible causes:

- Clunking noise from the rear: Could be caused by worn subframe bushings, worn suspension arm bushings, or a loose differential mount.

- Excessive wheel spin: Could be caused by an open differential, worn tires, or a weak engine.

- Vibration in the rear: Could be caused by worn axle shafts, unbalanced wheels, or a damaged driveshaft.

- Difficulty turning: Could be caused by a locked differential, incorrect suspension geometry, or worn tires.

- Rear end "squat" during acceleration: Could be caused by soft rear springs, worn shocks, or excessive weight transfer.

Always consult a qualified mechanic for diagnosis and repair of any serious problems with your 240SX rear subframe and differential assembly. Attempting repairs without proper knowledge and tools can be dangerous and may cause further damage.

Conclusion

The Nissan 240SX rear subframe and differential assembly is a crucial part of the car's performance and handling. Understanding the technical overview of this assembly is essential for maintenance, upgrades, and diagnosing potential issues. Whether you're a seasoned drifter, a weekend track warrior, or simply a 240SX enthusiast, knowledge of these components will help you keep your car running smoothly and performing its best. By properly maintaining and upgrading these components, you can unlock the full potential of your 240SX and enjoy its rear-wheel-drive capabilities to the fullest. Remember to always prioritize safety and seek professional help when needed. Understanding the technical details allows for informed decisions, contributing to the longevity and optimal performance of your beloved 240SX.