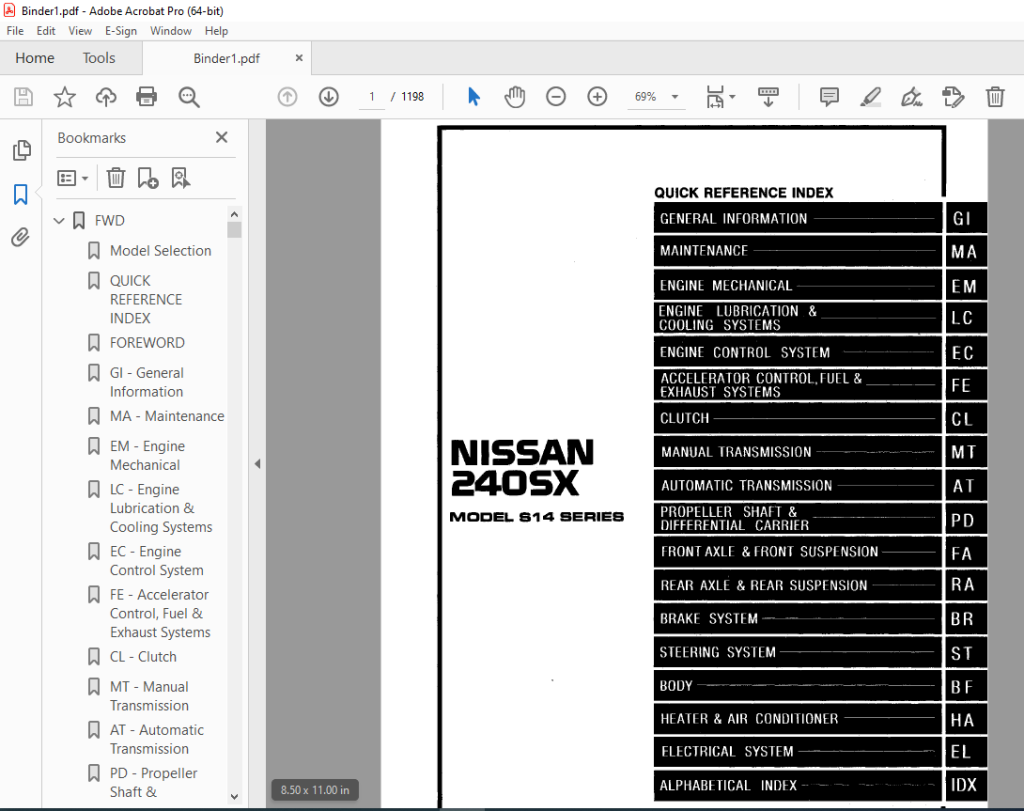

Technical Reference: The 1995 Nissan 240sx Factory Service Manual

Welcome, fellow 240SX enthusiast! You've stumbled upon a goldmine if you're wrestling with issues on your beloved 1995 Nissan 240SX. While online forums and YouTube tutorials are helpful, nothing beats the definitive resource: the 1995 Nissan 240SX Factory Service Manual (FSM). Think of it as the ultimate repair bible for your car. But navigating it can be daunting, so let's break down some common problems and how the FSM can guide you to a solution.

Common 240SX Issues and the FSM

Starting Problems: Fuel and Ignition System Checks

A no-start or hard-start condition is a frequent complaint. The FSM's Fuel System and Engine Electrical System sections are your first stops. The FSM provides comprehensive troubleshooting flowcharts, which are invaluable. You'll need a multimeter, basic hand tools (sockets, wrenches, screwdrivers), and possibly a fuel pressure gauge.

Common Culprits and FSM Guidance:

- Fuel Pump: The FSM details how to check fuel pump voltage and ground. It also outlines the fuel pressure testing procedure. You'll find the correct fuel pressure specifications within the fuel system section. A failing fuel pump relay or a clogged fuel filter (covered in the FSM's maintenance section) are also common causes.

- Ignition System: The FSM guides you through testing the ignition coil, distributor (if applicable, depending on if you're dealing with a KA24DE), igniter, and spark plugs. It specifies the correct resistance values for each component. Don't skip the basics: check the spark plug wires for damage and proper connections.

- Crankshaft Position Sensor (CKPS) / Camshaft Position Sensor (CMPS): These sensors are crucial for timing. The FSM shows you how to test their resistance and voltage output. A faulty CKPS or CMPS will almost certainly prevent the engine from starting.

- Mass Air Flow Sensor (MAF): The FSM explains how to check the MAF sensor's output voltage. A dirty or malfunctioning MAF can cause poor running and starting problems. Cleaning the MAF sensor with MAF cleaner (as instructed by the FSM - use the specified cleaner!) is a relatively easy fix.

Practical Tip: When checking electrical components, always refer to the FSM's wiring diagrams. These diagrams are incredibly detailed and show the exact location of connectors and grounds.

Approximate Repair Costs: A fuel pump can range from $80-$250 (aftermarket to OEM), an ignition coil from $30-$100 each, and a CKPS/CMPS from $50-$150 each. Labor costs will vary depending on your location and the mechanic's hourly rate, but replacing a fuel pump typically takes 1-3 hours, while sensor replacement can be quicker.

Overheating Issues: Cooling System Diagnosis

Overheating can lead to severe engine damage, so it's crucial to diagnose and fix the problem quickly. The FSM's Cooling System section is your go-to resource. You'll need a pressure tester (for the cooling system), a thermometer, and basic hand tools.

Common Culprits and FSM Guidance:

- Radiator: The FSM details how to inspect the radiator for leaks and blockages. A clogged radiator will restrict coolant flow and cause overheating. Flushing the radiator (as described in the FSM's maintenance section) may resolve the issue.

- Thermostat: The FSM outlines how to test the thermostat to ensure it's opening and closing properly. A stuck-closed thermostat will prevent coolant from circulating through the engine.

- Water Pump: The FSM explains how to inspect the water pump for leaks and proper operation. A failing water pump won't circulate coolant effectively. Listen for unusual noises coming from the water pump area; this could indicate a failing bearing.

- Cooling Fan(s): The FSM shows how to check the cooling fan(s) for proper operation. Ensure the fan(s) are turning on when the engine reaches a certain temperature (the FSM specifies this temperature). Check the fan clutch (if equipped) for proper engagement.

- Head Gasket: If you suspect a blown head gasket, the FSM describes how to perform a compression test. Low compression in one or more cylinders, along with other symptoms like coolant loss and white smoke from the exhaust, can indicate a head gasket failure. This is a serious repair!

Practical Tip: When pressure testing the cooling system, carefully follow the FSM's instructions. Over-pressurizing the system can damage components.

Approximate Repair Costs: A radiator can range from $100-$300, a thermostat from $20-$50, and a water pump from $50-$200. A head gasket replacement is a more involved repair, potentially costing $800-$2000, including parts and labor.

Suspension and Handling Problems: Identifying and Addressing Issues

The 240SX is known for its handling, so any degradation in performance is noticeable. The FSM's Suspension section will be your friend here. You'll need a jack, jack stands, wrenches, sockets, and potentially a ball joint separator or pickle fork.

Common Culprits and FSM Guidance:

- Worn Bushings: The FSM provides detailed diagrams of all suspension components and bushing locations. Worn bushings can cause sloppy handling, clunking noises, and uneven tire wear. Inspect all bushings for cracks, tears, and excessive play. The FSM will outline the correct installation procedure and torque specs for replacement bushings.

- Ball Joints and Tie Rod Ends: The FSM explains how to inspect ball joints and tie rod ends for play. Excessive play in these components can lead to dangerous handling characteristics. Use a dial indicator (as instructed in the FSM) for precise measurement of play.

- Shocks and Struts: The FSM describes how to test shocks and struts for proper damping. Leaking shocks or struts that have lost their damping ability will result in a bouncy ride and poor handling. Look for visual signs of leaking fluid.

- Wheel Bearings: The FSM outlines the procedure for inspecting wheel bearings for play and noise. A worn wheel bearing can cause a rumbling noise that increases with speed. Excessive play in the wheel bearing is a sign of imminent failure.

Practical Tip: When replacing suspension components, always torque the fasteners to the specifications listed in the FSM. Under-torquing can lead to loosening, while over-torquing can damage the components.

Approximate Repair Costs: Bushings can range from $5-$30 each, ball joints and tie rod ends from $30-$80 each, shocks and struts from $50-$200 each (depending on brand and type), and wheel bearings from $40-$100 each.

Electrical Gremlins: Wiring Diagrams are Your Savior

Electrical issues can be frustrating to diagnose. The FSM's comprehensive wiring diagrams are essential for tracing circuits and finding shorts or opens. You'll need a multimeter and a test light.

Common Culprits and FSM Guidance:

- Blown Fuses: The FSM lists the location and function of all fuses in the car. Start by checking the fuse box for blown fuses. But, don't just replace the fuse; find the cause of the short circuit! The FSM wiring diagrams will help you trace the circuit to identify the problem.

- Faulty Relays: Relays control various electrical components. The FSM describes how to test relays for proper operation. Swap a known good relay with the suspected faulty relay to see if the problem is resolved.

- Grounding Issues: Poor grounds can cause a variety of electrical problems. The FSM shows the location of all ground points in the car. Clean and tighten the ground connections to ensure a good electrical connection.

- Wiring Harness Damage: Inspect the wiring harness for damage, such as frayed wires or corroded connectors. Use the FSM wiring diagrams to identify the correct wires and connectors. Repair or replace damaged wiring as needed.

Practical Tip: When working on electrical systems, always disconnect the negative battery cable to prevent short circuits.

Approximate Repair Costs: Fuses are inexpensive, relays can range from $10-$30, and wiring harness repairs can vary greatly depending on the severity of the damage.

Navigating the FSM Effectively

- Know Your Model Year: The 1995 FSM is specific to the 1995 model year. While some information may be applicable to other years, there can be differences.

- Use the Index: The FSM has a comprehensive index that lists all topics covered in the manual. Use the index to quickly find the information you need.

- Read the Introduction: The introduction provides an overview of the FSM and explains how to use it effectively.

- Refer to the Wiring Diagrams: The wiring diagrams are essential for troubleshooting electrical problems. Take the time to understand how to read them.

- Follow the Troubleshooting Flowcharts: The troubleshooting flowcharts are a step-by-step guide to diagnosing problems. Follow the flowcharts carefully to ensure you don't miss any steps.

- Double-Check Specifications: Always double-check the specifications listed in the FSM before performing any repairs. This includes torque specifications, fluid capacities, and electrical values.

Important Note: The FSM is a valuable resource, but it's not a substitute for experience. If you're not comfortable performing a particular repair, it's best to take your car to a qualified mechanic.

By utilizing the 1995 Nissan 240SX Factory Service Manual, you'll be well-equipped to tackle a wide range of repairs and maintenance tasks, keeping your 240SX running smoothly for years to come. Good luck, and happy wrenching!