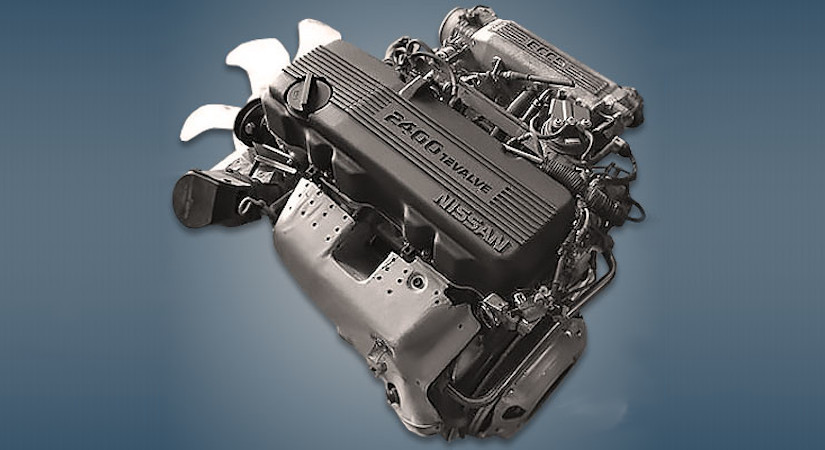

Technical Specifications Of The 1990 Nissan 240sx Ka24e Engine

The 1990 Nissan 240SX, a beloved icon of the drift and tuning scene, owes much of its enduring appeal to its robust and relatively simple engine. While later models received the dual-overhead cam KA24DE, the 1990 model year featured the single-overhead cam KA24E. This engine, though often overlooked in favor of its more powerful successor, is a capable powerplant in its own right. This article delves into the technical specifications of the KA24E, providing a detailed look at its design, components, and performance characteristics.

Engine Overview: A Solid Foundation

The KA24E is a 2.4-liter (2389 cc) inline four-cylinder engine. Its designation breaks down as follows: "KA" signifies the engine family, "24" indicates the displacement (2.4 liters), and "E" denotes electronic fuel injection. This engine was designed with reliability and fuel efficiency in mind, characteristics that contributed to the 240SX's success as a daily driver. However, its over-engineered block also hinted at untapped potential, later exploited by enthusiasts seeking more performance.

Block and Crankshaft

The KA24E utilizes a cast-iron engine block, chosen for its strength and durability. Cast iron is inherently more robust than aluminum, making it well-suited for handling the stresses of combustion and extended use. The block features a square 89mm bore and 96mm stroke, resulting in an undersquare engine design. This longer stroke contributes to increased low-end torque, a desirable characteristic for street driving. The crankshaft is made from forged steel, further enhancing the engine's durability. It's supported by five main bearings, ensuring crankshaft stability and reducing friction.

Key Specification: The bore and stroke are 89mm x 96mm.

Cylinder Head and Valvetrain

The cylinder head of the KA24E is constructed from aluminum alloy. This material offers superior heat dissipation compared to cast iron, helping to prevent overheating and improve combustion efficiency. The head employs a single overhead camshaft (SOHC) design, operating two valves per cylinder (eight valves total). The valvetrain is relatively simple, using rocker arms to actuate the valves. This simplicity contributes to the engine's reliability and ease of maintenance.

The camshaft is driven by a timing chain, which is known for its durability and reliability compared to timing belts. While chains can stretch over time, they generally require less frequent replacement. The rocker arms are equipped with hydraulic lash adjusters, which automatically maintain the correct valve lash, reducing noise and wear.

Key Specification: SOHC, 2 valves per cylinder (8 total).

Fuel and Ignition Systems

The KA24E uses an electronic fuel injection (EFI) system to deliver fuel to the cylinders. This system provides precise fuel metering, resulting in improved fuel efficiency and reduced emissions compared to carburetors. The EFI system is controlled by an engine control unit (ECU), which monitors various engine parameters such as air intake, engine speed, and coolant temperature to optimize fuel delivery and ignition timing. The fuel injectors are located in the intake manifold, spraying fuel into the intake ports just before the intake valves.

The ignition system is a distributor-based system. The distributor is driven by the camshaft and distributes high-voltage electricity to the spark plugs in the correct firing order. The spark plugs ignite the air-fuel mixture in the cylinders, initiating the combustion process. The ignition timing is controlled by the ECU, which adjusts the timing based on engine speed and load. The firing order is 1-3-4-2, a standard firing order for inline four-cylinder engines.

Key Components: ECU controlled EFI, distributor-based ignition.

Intake and Exhaust Systems

The intake manifold is a relatively simple design, constructed from cast aluminum. It directs air from the throttle body to the intake ports on the cylinder head. The design is optimized for smooth airflow and minimal restriction. The throttle body controls the amount of air entering the engine, which is regulated by the accelerator pedal.

The exhaust manifold is made from cast iron and is designed to collect exhaust gases from the cylinders and direct them to the exhaust system. The exhaust system includes a catalytic converter, which reduces harmful emissions. The exhaust system's design affects the engine's performance, with larger diameter pipes generally improving exhaust flow and increasing horsepower, especially at higher RPMs. However, the stock exhaust system is designed for a balance of performance and noise reduction.

Lubrication and Cooling Systems

The KA24E uses a wet-sump lubrication system, where the oil is stored in the oil pan at the bottom of the engine. An oil pump, driven by the crankshaft, circulates the oil throughout the engine, lubricating the moving parts and removing heat. The oil filter removes contaminants from the oil, ensuring its cleanliness and prolonging the engine's life. The recommended oil viscosity is typically 10W-30 or 10W-40, depending on the climate and driving conditions.

The cooling system uses a water pump to circulate coolant throughout the engine and radiator. The radiator dissipates heat from the coolant, keeping the engine at its optimal operating temperature. A thermostat regulates the flow of coolant, ensuring that the engine warms up quickly and maintains a consistent temperature. The KA24E is known for its robust cooling system, contributing to its overall reliability.

Performance Specifications

The 1990 KA24E produces approximately 140 horsepower at 5600 RPM and 152 lb-ft of torque at 4400 RPM. These figures are respectable for a naturally aspirated 2.4-liter engine of its time. The engine's relatively flat torque curve provides good acceleration throughout the RPM range, making it suitable for both city and highway driving. While not a powerhouse, the KA24E offered a good balance of performance, fuel efficiency, and reliability.

Key Performance Figures: 140 hp @ 5600 RPM, 152 lb-ft @ 4400 RPM.

Common Issues and Reliability

The KA24E is generally considered a reliable engine, but like any engine, it is prone to certain issues. One common issue is timing chain stretch, which can lead to reduced performance and increased engine noise. Regular oil changes are crucial to preventing timing chain wear. Another potential problem is oil leaks, particularly from the valve cover gasket and front main seal. These leaks are usually minor and can be easily addressed by replacing the gaskets or seals.

Overall, the KA24E is a well-engineered and durable engine. With proper maintenance, it can provide many years of reliable service. Its simplicity and robust design make it a popular choice for enthusiasts who are looking for a dependable and affordable engine.

Tuning Potential and Aftermarket Support

While the KA24E might not be the first choice for high-horsepower builds, it still offers some tuning potential. Common modifications include upgrading the exhaust system, installing a cold air intake, and tuning the ECU. These modifications can improve airflow and optimize fuel delivery, resulting in modest power gains. However, significant power increases typically require more extensive modifications, such as installing a performance camshaft and increasing the compression ratio.

The aftermarket support for the KA24E is relatively good, with a wide range of performance parts available. This allows enthusiasts to customize their engines to suit their specific needs and goals. However, it is important to note that the KA24DE engine generally offers greater tuning potential due to its dual-overhead cam design and increased airflow capabilities.

In conclusion, the 1990 Nissan 240SX's KA24E engine, while not the most powerful, is a testament to robust engineering and reliable performance. Its simple design, combined with a durable construction, made it a dependable powerplant for years to come. Understanding its technical specifications provides valuable insight into the engine's capabilities and limitations, as well as its potential for modification and improvement. The KA24E's legacy lives on through the enthusiasts who continue to appreciate its strengths and explore its untapped potential.