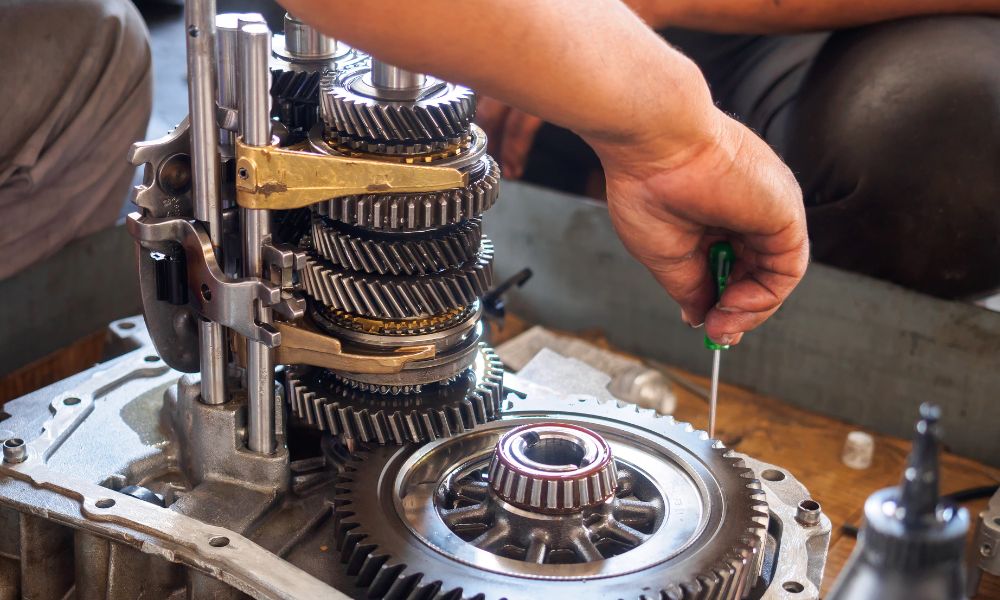

Transmission Removal Procedures And Special Tools Required

Removing a transmission is a significant undertaking, requiring careful planning, the right tools, and a solid understanding of the procedures involved. This article provides a general overview of the process and highlights the special tools you'll likely need. Remember, safety is paramount. If you are not comfortable performing this task, consult a qualified mechanic.

Understanding the Scope: Is This a DIY Project?

Before diving in, honestly assess your mechanical skills and experience. Removing a transmission involves disconnecting numerous components, working under a potentially heavy vehicle, and handling a heavy transmission unit. Improperly disconnecting lines, damaging sensors, or dropping the transmission can lead to costly repairs or even injury. Consider these factors:

- Your Experience: Have you performed similar automotive repairs before? Are you comfortable working with tools and following detailed instructions?

- Vehicle Specifics: Each vehicle model has its own unique layout and potential challenges. Research your specific vehicle extensively.

- Physical Capability: Removing a transmission can be physically demanding. Be realistic about your ability to lift and maneuver heavy objects.

If you're unsure, it's always best to consult with a professional mechanic. They have the expertise and equipment to perform the job safely and efficiently.

Essential Tools for Transmission Removal

Having the right tools is crucial for a successful transmission removal. Here's a list of tools you'll likely need:

General Hand Tools:

- Socket Set (Metric and/or SAE): Covering a wide range of sizes is essential for removing bolts and nuts. A 6-point socket set is preferred to minimize the risk of rounding off fasteners.

- Wrench Set (Metric and/or SAE): Open-end, box-end, and combination wrenches are necessary for various connections.

- Screwdrivers (Phillips and Flathead): Needed for removing various screws and clips.

- Pliers: Including standard pliers, needle-nose pliers, and possibly locking pliers (Vise-Grips).

- Hammer: A dead blow hammer is recommended to avoid damaging components.

- Punch and Chisel Set: May be needed to remove stubborn pins or fasteners.

Specialized Tools:

- Floor Jack and Jack Stands: A heavy-duty floor jack and sturdy jack stands are absolutely essential for safely raising and supporting the vehicle. Never work under a vehicle supported only by a jack.

- Transmission Jack: This is perhaps the most critical specialized tool. A transmission jack is designed specifically to support and lower the heavy transmission safely and controllably. Don't attempt to remove a transmission without one.

- Wheel Chocks: Secure the rear wheels (if lifting the front) or front wheels (if lifting the rear) to prevent the vehicle from rolling.

- Penetrating Oil: Apply liberally to rusted or stuck bolts and nuts to help loosen them.

- Torque Wrench: Essential for properly tightening bolts to the manufacturer's specifications during reinstallation.

- Drain Pan: To catch transmission fluid when disconnecting lines.

- Safety Glasses: Protect your eyes from flying debris and fluids.

- Gloves: Protect your hands from grease, oil, and sharp edges.

- Parts Trays: Keep track of all removed bolts, nuts, and small parts. Labeling them is also highly recommended.

- Service Manual (for your specific vehicle): This is your bible. It provides detailed instructions, diagrams, and torque specifications for your specific vehicle model.

- OBD-II Scanner: Needed to clear any trouble codes that may arise during the process or to diagnose any pre-existing issues that might have contributed to the transmission failure.

- Alignment Tool (for Manual Transmissions): This tool is essential to align the clutch disc during reinstallation of a manual transmission, allowing the input shaft to slide into the pilot bearing.

General Transmission Removal Procedure (Overview)

This is a general outline. Refer to your vehicle's service manual for specific instructions.

- Preparation:

- Consult your service manual.

- Gather all necessary tools and supplies.

- Safely raise and support the vehicle using a floor jack and jack stands. Ensure the vehicle is stable and secure.

- Disconnect the negative battery cable to prevent electrical shorts.

- Drain the transmission fluid.

- Disconnecting Components:

- Remove the driveshaft (or half-shafts for front-wheel-drive vehicles).

- Disconnect any wiring harnesses connected to the transmission, carefully labeling each connection.

- Disconnect shift linkage or cable.

- Disconnect the speedometer cable or sensor.

- Remove any exhaust components that are in the way.

- Disconnect any cooler lines or hoses.

- Supporting the Engine:

- For some vehicles, you may need to support the engine from above with an engine support bar. This prevents the engine from tilting when the transmission is removed.

- Removing the Transmission Mount:

- Remove the bolts securing the transmission mount to the vehicle's frame or crossmember.

- Supporting the Transmission:

- Position the transmission jack under the transmission and secure it properly. Make sure the transmission is balanced on the jack.

- Removing Transmission Bolts:

- Carefully remove the bolts connecting the transmission to the engine. These bolts can be very tight.

- Lowering the Transmission:

- Slowly and carefully lower the transmission using the transmission jack. Make sure nothing is binding or snagging.

- Once the transmission is clear of the vehicle, carefully remove it from under the vehicle.

Important Considerations During Reinstallation

Reinstallation is essentially the reverse of removal, but with a few key considerations:

- Cleanliness: Ensure all mating surfaces are clean and free of debris.

- New Seals and Gaskets: Replace any seals or gaskets that were disturbed during the removal process.

- Torque Specifications: Use a torque wrench to tighten all bolts to the manufacturer's specified torque. Over-tightening or under-tightening can lead to problems.

- Alignment: Ensure proper alignment of all components during reinstallation. For manual transmissions, the clutch disc must be properly aligned using an alignment tool.

- Fluid Levels: Refill the transmission with the correct type and amount of fluid.

- Test Drive: After reinstallation, perform a thorough test drive to ensure the transmission is operating properly. Check for any leaks or unusual noises.

Safety Precautions

Safety should always be your top priority when working on vehicles.

- Wear safety glasses and gloves at all times.

- Never work under a vehicle supported only by a jack. Always use jack stands.

- Disconnect the negative battery cable before starting any electrical work.

- Use caution when handling fluids, as some can be harmful.

- Dispose of used fluids properly.

- If you are unsure about any step, consult a qualified mechanic.

Conclusion

Removing a transmission is a challenging task that requires careful planning, the right tools, and a thorough understanding of the procedures involved. While it's possible to do it yourself, it's important to honestly assess your skills and experience before attempting this project. If you're not comfortable, seeking professional assistance is always the safest and most reliable option. Remember to always prioritize safety and consult your vehicle's service manual for specific instructions.