What Does Refill Inverter Coolant Mean

The world of hybrid and electric vehicles (EVs) is filled with intriguing technologies, often hidden beneath sleek body panels and quiet operation. One crucial, but sometimes overlooked, aspect is the inverter coolant system. When your dashboard displays a message like "Refill Inverter Coolant," it's not just a suggestion; it's an indicator of a potentially serious issue that demands attention. But what exactly *is* inverter coolant, and why does it need refilling? This article delves into the inner workings of the inverter coolant system, explaining its purpose, components, and the importance of maintaining its integrity.

What is an Inverter and Why Does It Need Cooling?

At the heart of every hybrid and electric vehicle lies the inverter. Think of it as the electrical translator of the car. Batteries in these vehicles store energy in the form of direct current (DC) electricity. However, the electric motors that actually propel the vehicle require alternating current (AC). The inverter's job is to efficiently convert the DC power from the battery into the AC power needed by the motor. It also performs the reverse function during regenerative braking, converting AC power from the motor back into DC power to recharge the battery.

This conversion process isn't perfect. Like any electrical component, the inverter generates heat as a byproduct of its operation. And it generates a *lot* of heat. Modern inverters often handle hundreds of amps and hundreds of volts, switching this current at very high frequencies. This switching action, combined with internal resistance, leads to significant power dissipation in the form of thermal energy. Without effective cooling, the inverter's internal components, such as insulated-gate bipolar transistors (IGBTs) and diodes, would quickly overheat and fail. Overheating can lead to reduced performance, premature component degradation, and in the worst-case scenario, complete inverter failure, rendering the vehicle immobile.

The Inverter Coolant System: Anatomy and Function

The inverter coolant system is designed to maintain the inverter within its optimal operating temperature range, preventing overheating and ensuring its longevity and performance. It's a closed-loop system, much like the engine cooling system in a traditional internal combustion engine (ICE) vehicle, but with some key differences. While some EVs use the same coolant loop for both the battery pack and the inverter, many dedicated inverter cooling loops provide more precise temperature control.

Here's a breakdown of the typical components of an inverter coolant system:

- Coolant: This is the lifeblood of the system. It's usually a specially formulated ethylene glycol or propylene glycol based coolant with additives to prevent corrosion and scale buildup within the system. Importantly, the coolant must be compatible with the sensitive electronic components in the inverter and the materials used in the cooling system. Using the wrong type of coolant can lead to corrosion, leaks, and damage to the inverter. EV coolants are often dielectric (non-conductive) to avoid short circuits in the event of a leak.

- Coolant Pump: This circulates the coolant throughout the system, ensuring a continuous flow of heat transfer. Unlike the mechanically driven water pump in many ICE vehicles, the inverter coolant pump is typically an electric pump, allowing for independent control and optimized cooling based on the inverter's operating temperature. This pump's speed can be varied by the vehicle's electronic control unit (ECU) based on real-time cooling needs.

- Coolant Reservoir: This provides a space for coolant expansion and contraction due to temperature changes. It also acts as a point for visually checking the coolant level. The reservoir often has "MIN" and "MAX" markings to indicate the acceptable coolant level range.

- Heat Exchanger (Radiator): This dissipates the heat absorbed from the inverter into the surrounding air. It's essentially a small radiator, similar to the main engine radiator, but often smaller and dedicated to the inverter cooling loop. Airflow through the heat exchanger is crucial for effective cooling, and some systems incorporate electric fans to enhance airflow. The location of this heat exchanger varies by vehicle model, but it's often located in the front of the vehicle, near the main radiator.

- Connecting Hoses and Pipes: These provide the pathways for the coolant to circulate between the various components of the system. These hoses are designed to withstand high temperatures and pressures, and they must be resistant to the chemical properties of the coolant.

- Temperature Sensors: These monitor the coolant temperature at various points in the system, providing feedback to the vehicle's ECU. This information is used to control the coolant pump speed, fan operation, and to alert the driver if the coolant temperature exceeds safe limits.

The coolant flows from the reservoir, through the pump, into the inverter where it absorbs heat, then to the heat exchanger where the heat is dissipated, and finally back to the reservoir, completing the cycle. The ECU constantly monitors the temperature and adjusts the pump speed and fan operation to maintain optimal inverter temperature.

Why Does Inverter Coolant Need Refilling?

Several factors can contribute to a low inverter coolant level, triggering the "Refill Inverter Coolant" warning:

- Leaks: This is the most common reason. Leaks can occur at hose connections, the coolant pump, the heat exchanger, or even within the inverter itself. Even small leaks can gradually deplete the coolant level over time.

- Evaporation: While the system is sealed, some evaporation of coolant can occur, especially in hot climates. Over several years, this can lower the coolant level.

- Air Entrapment: When the system is initially filled or after maintenance, air pockets can become trapped within the system. As the air is purged, it's replaced by coolant, leading to a drop in the coolant level. This is why it's important to properly bleed the system after any service.

- Coolant Degradation: Over time, the coolant's chemical properties can degrade, reducing its ability to effectively transfer heat and protect against corrosion. While this doesn't directly cause the coolant level to drop, degraded coolant puts more strain on the system, potentially leading to higher operating temperatures and increased risk of leaks or component failure.

What Happens If You Ignore the Warning?

Ignoring the "Refill Inverter Coolant" warning can have serious consequences. As the coolant level drops, the inverter's ability to dissipate heat is reduced. This can lead to:

- Reduced Performance: The inverter may be forced to reduce its output power to prevent overheating, resulting in reduced vehicle acceleration and top speed.

- Component Damage: Prolonged overheating can damage the sensitive electronic components within the inverter, leading to premature failure. This can be a very expensive repair.

- Inverter Failure: In extreme cases, overheating can cause the inverter to fail completely, leaving you stranded.

- Reduced Battery Life: An overheated inverter can also impact battery performance and longevity. The higher operating temperatures can put additional stress on the battery pack.

Troubleshooting and Refilling the Inverter Coolant

If you receive a "Refill Inverter Coolant" warning, it's crucial to investigate the cause. Here's a basic troubleshooting process:

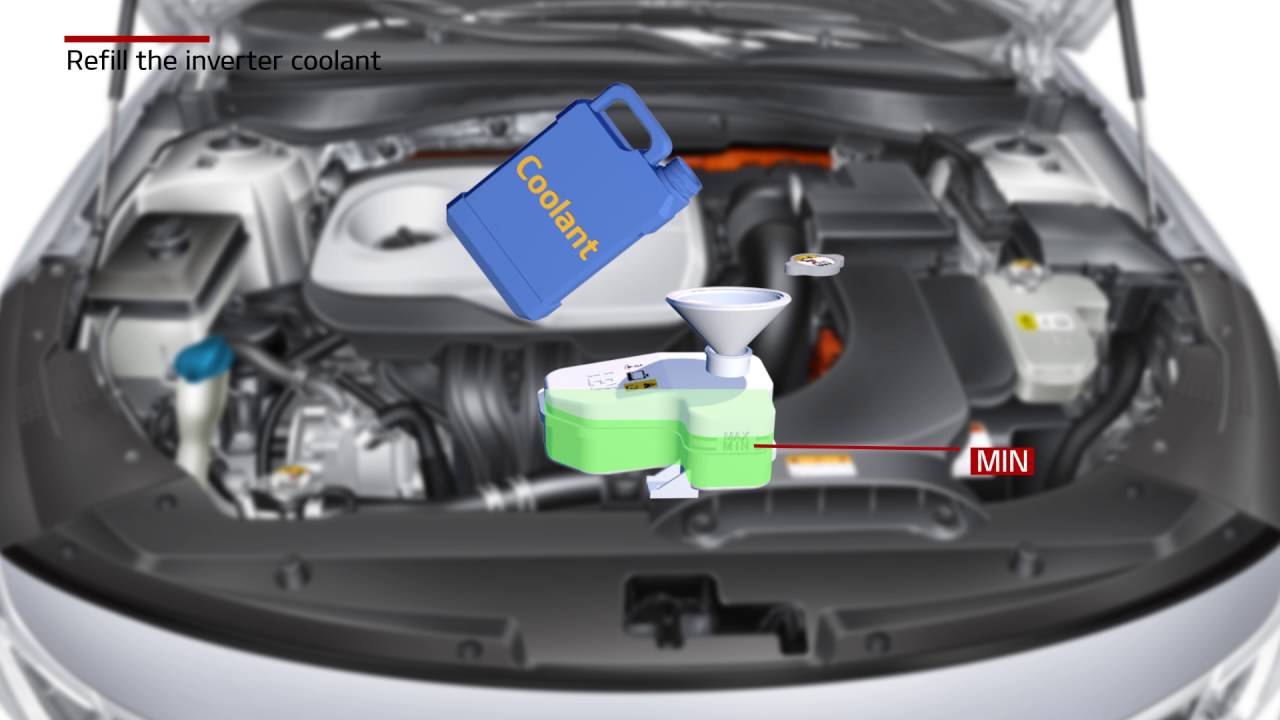

- Check the Coolant Level: Locate the inverter coolant reservoir (refer to your vehicle's owner's manual for its location). Visually inspect the coolant level. If it's below the "MIN" mark, you need to add coolant.

- Inspect for Leaks: Carefully examine the hoses, connections, coolant pump, and heat exchanger for any signs of leaks. Look for wet spots, coolant residue, or corrosion.

- Determine the Correct Coolant Type: Refer to your vehicle's owner's manual to identify the correct type of coolant for the inverter system. Using the wrong coolant can cause significant damage!

- Refill the Coolant: Slowly add coolant to the reservoir until it reaches the "MAX" mark. Be careful not to overfill.

- Monitor the Coolant Level: After refilling, monitor the coolant level for a few days to ensure there are no further leaks.

Important Safety Note: Work with coolant should always be done with appropriate safety precautions. Wear gloves and eye protection to avoid contact with the coolant. Coolant is toxic and should not be ingested.

If you're unable to identify the source of the leak or if the coolant level continues to drop after refilling, it's essential to take your vehicle to a qualified technician for inspection and repair. A professional can perform a pressure test to identify even small leaks and can properly diagnose and repair any underlying issues with the cooling system.

Preventative Maintenance

Regular maintenance can help prevent inverter coolant problems. Here are some tips:

- Check the Coolant Level Regularly: Make it a habit to check the inverter coolant level periodically, especially before long trips.

- Follow the Recommended Coolant Change Interval: Refer to your vehicle's owner's manual for the recommended coolant change interval. Changing the coolant at the specified interval helps maintain its effectiveness and prevents corrosion.

- Inspect Hoses and Connections: Periodically inspect the hoses and connections for signs of cracking, wear, or leaks.

By understanding the function and importance of the inverter coolant system, and by performing regular maintenance, you can help ensure the longevity and performance of your hybrid or electric vehicle's powertrain.