Wheel And Tire Package Load Rating And Clearance Calculations

Choosing the right wheel and tire package for your vehicle goes far beyond aesthetics. While a new set of wheels and tires can dramatically improve the look of your ride, it's absolutely critical to ensure they meet or exceed the load rating requirements and provide sufficient clearance. Ignoring these factors can lead to serious safety issues, handling problems, and even damage to your vehicle. This article will guide you through the process of calculating load ratings and clearance, ensuring you select a wheel and tire package that is both safe and performs as intended.

Understanding Load Rating

The load rating of a tire (and, less commonly, a wheel) is a numerical code that corresponds to the maximum weight that tire can safely support when properly inflated. It's a critical safety consideration and should never be ignored. Overloading your tires can lead to tire failure, which can have catastrophic consequences. The load index is a two- or three-digit number molded into the sidewall of the tire, usually near the tire size. You'll need a load index chart (easily found online) to translate this number into a weight in pounds or kilograms.

Example: A tire with a load index of 91 indicates a maximum load capacity of 1356 lbs (615 kg). It's important to note that this is the load capacity for one tire. You need to consider the entire axle load.

Calculating Axle Load and Required Load Rating

To determine the minimum required load rating for your tires, you'll need to find your vehicle's Gross Axle Weight Rating (GAWR). The GAWR specifies the maximum allowable weight that can be supported by each axle (front and rear). You can typically find the GAWR on a sticker located on the driver's side doorjamb or in your vehicle's owner's manual. It's usually expressed in both pounds and kilograms.

- Find the GAWR for both the front and rear axles. Let's say your vehicle has a front GAWR of 2400 lbs and a rear GAWR of 2600 lbs.

- Divide each GAWR by 2. This gives you the weight that each tire on that axle must be able to support.

- Front: 2400 lbs / 2 = 1200 lbs per tire

- Rear: 2600 lbs / 2 = 1300 lbs per tire

- Determine the minimum required load index. Using a load index chart, find the load index that corresponds to at least 1200 lbs (for the front) and 1300 lbs (for the rear). You may need different tires on front and rear if required. For our example, we need a minimum load index of approximately 86 (1202 lbs) for the front and 89 (1279 lbs) for the rear.

- Select tires with a load index that meets or exceeds these minimum requirements. Never choose tires with a lower load index than required, even if they seem close. It's always better to err on the side of safety.

Important Considerations:

- Never use the vehicle's Gross Vehicle Weight Rating (GVWR) for this calculation. The GVWR represents the total weight of the vehicle and its contents, not the individual axle loads.

- Consider future modifications and usage. If you plan on frequently carrying heavy loads or towing, it's wise to choose tires with a higher load index than the minimum required.

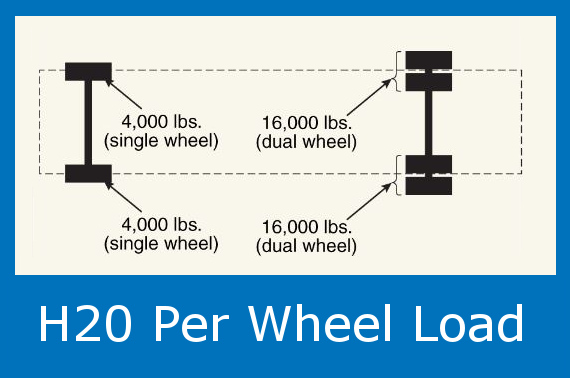

- Wheel Load Rating: While less common to be a limiting factor, ensure that the wheels you select are rated to handle the weight of the vehicle. Wheel load ratings are determined by the manufacturer and should be confirmed before purchase.

Understanding Wheel and Tire Clearance

Clearance refers to the amount of space between your wheels/tires and various parts of your vehicle, such as the suspension components, fenders, brake calipers, and inner wheel well. Insufficient clearance can lead to rubbing, which can damage your tires, suspension, and bodywork. Proper clearance ensures that your wheels and tires can move freely through their full range of motion without interference.

Key Clearance Factors

Several factors influence wheel and tire clearance, including:

- Tire Size: Wider and taller tires require more clearance. Tire size is typically expressed in a format like "225/45R17". The first number (225) is the tire width in millimeters, the second number (45) is the aspect ratio (the height of the sidewall as a percentage of the width), and the third number (17) is the wheel diameter in inches.

- Wheel Offset: Offset is the distance between the wheel's mounting surface and its centerline. A positive offset means the mounting surface is closer to the outside of the wheel, while a negative offset means it's closer to the inside. Offset affects how far the wheel sticks out or tucks in, impacting fender and suspension clearance.

- Wheel Width: Wider wheels will extend further outward and inward, potentially causing rubbing issues.

- Suspension Modifications: Lowering your vehicle can significantly reduce wheel well clearance, requiring careful consideration of tire size and wheel offset.

- Brake Caliper Size: Larger aftermarket brake calipers may require wheels with specific spoke designs to provide sufficient clearance.

Calculating and Measuring Clearance

Accurately measuring and calculating clearance can be challenging, but there are several methods you can use:

- Online Tire Size Calculators: These tools allow you to compare different tire sizes and visualize how they will affect clearance. Input your current tire size and the desired new size, and the calculator will provide information about diameter, width, and sidewall height differences. This is a good starting point for understanding the potential impact of a size change.

- Wheel Offset Calculators: Similar to tire size calculators, these tools help you understand how wheel offset affects wheel position relative to your suspension and fenders. You can input your current wheel offset and the desired offset to see how the wheel will move inward or outward.

- Physical Measurements: This is the most accurate way to determine clearance. Here's how to do it:

- Static Clearance: With the vehicle parked on a level surface, turn the steering wheel lock-to-lock and inspect the clearance between the existing wheels/tires and all surrounding components (fenders, suspension, brake calipers, etc.). Note any areas where clearance is tight.

- Dynamic Clearance: This is more difficult to assess but crucial. With the vehicle safely supported on jack stands, cycle the suspension through its full range of motion (if possible). Observe the clearance as the suspension compresses and rebounds. Pay close attention to areas where rubbing is likely to occur. It is generally not safe or practical to cycle the suspension with the tires on unless a two post lift is available. Alternatively, measure the remaining space using a wheel fitment tool or a series of straight edges, levels, and rulers.

- Test Fitting: If possible, test fit the new wheels and tires before purchasing them. This allows you to visually inspect the clearance and identify any potential issues before committing to the purchase. Many tire shops will allow you to test fit wheels and tires.

Addressing Clearance Issues

If you encounter clearance issues, there are several options you can consider:

- Choosing a Different Tire Size: Selecting a narrower or shorter tire can improve clearance.

- Adjusting Wheel Offset: Choosing a wheel with a different offset can move the wheel inward or outward, providing more clearance where needed. However, be aware that changing the offset can affect handling characteristics.

- Using Wheel Spacers: Wheel spacers push the wheel further outward, increasing clearance between the wheel and suspension components. However, using spacers can put additional stress on wheel bearings and suspension parts. Ensure that you use high-quality hub-centric spacers of the correct thickness. Also, carefully consider any rubbing issues that may arise on the outer fender.

- Rolling Fenders: Fender rolling involves using a specialized tool to gently bend the inner fender lip outward, creating more clearance for the tires.

- Minor fender modifications: While more extreme, some choose to modify the fenders through cutting or flaring to maximize clearance. This should only be done by experienced professionals.

- Adjusting Suspension Settings: On vehicles with adjustable suspension, you may be able to raise the ride height or adjust camber to improve clearance.

Important Safety Notes:

Always consult with a qualified mechanic or tire specialist before making any significant changes to your wheel and tire setup. They can help you assess your vehicle's specific needs and ensure that your chosen package is safe and appropriate.

Never compromise on safety for aesthetics. Choosing wheels and tires that meet or exceed the load rating requirements and provide adequate clearance is essential for safe and reliable driving.

Always torque lug nuts to the manufacturer's specifications and re-torque them after the first 50-100 miles of driving with new wheels.