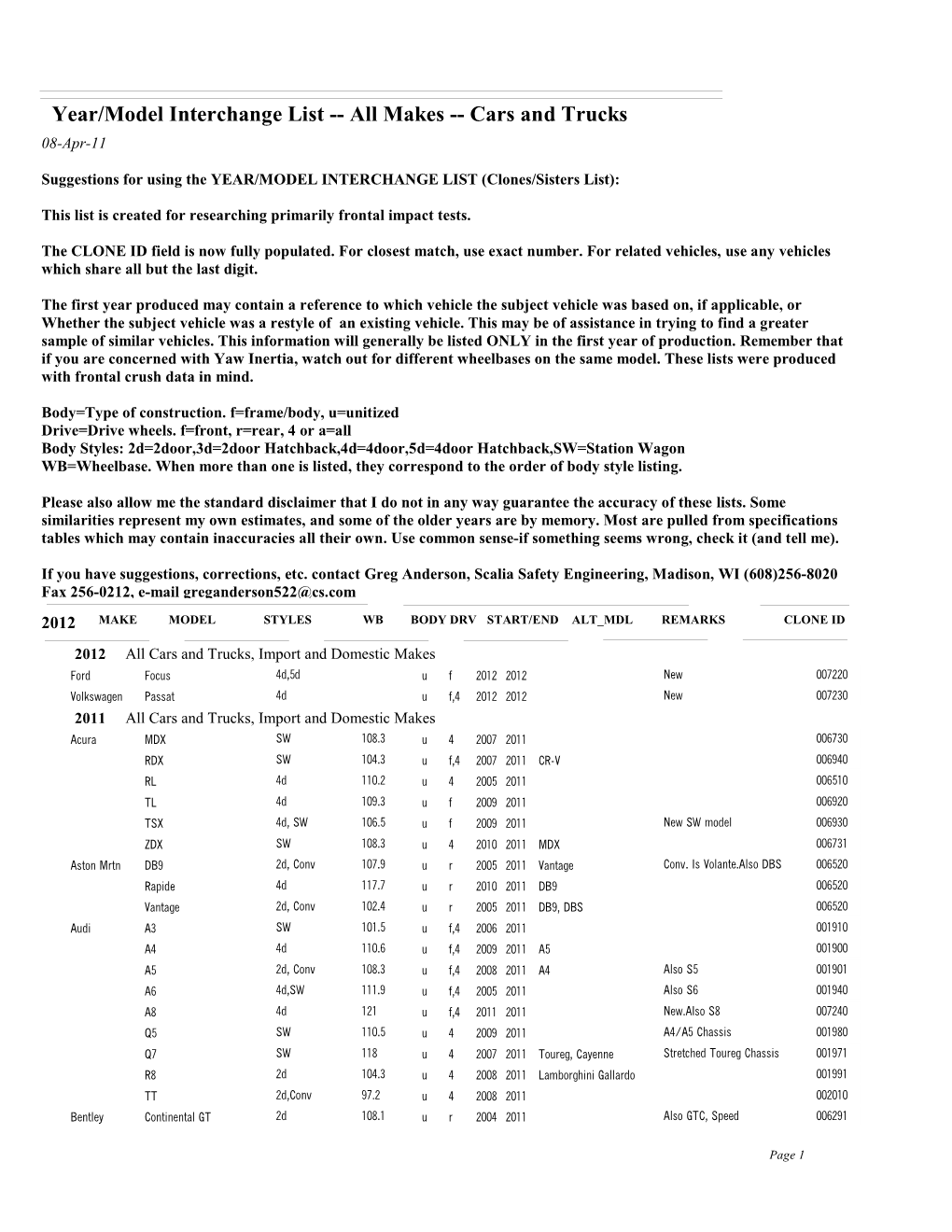

Year/model Interchange List -- All Makes -- Cars And Trucks

The world of automotive engineering, at first glance, appears to be a collection of disparate, brand-specific components meticulously designed for individual vehicles. However, beneath the surface lies a complex web of interchangeability, where parts designed for one make and model can often be adapted, or even directly installed, into another. This concept, known as parts interchangeability, has been a cornerstone of the automotive industry since its inception, driven by factors ranging from cost savings and manufacturing efficiency to creative problem-solving in repair scenarios and even performance enhancements.

Understanding the Drivers of Interchangeability

Several key factors contribute to the prevalence of parts interchangeability. These drivers fall into a few major categories:

Standardization

One of the most significant enablers is the use of standardized parts and dimensions. Organizations like the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO) establish industry-wide standards for components like fasteners (nuts, bolts, screws), fluid fittings, electrical connectors, and even basic mechanical components. While these standards don't guarantee interchangeability in all applications, they significantly increase the likelihood, especially for non-critical components.

For example, a standard size metric bolt, like an M8-1.25, will, by definition, fit any threaded hole designed to accept that size bolt, regardless of the vehicle's manufacturer. This is a simple but powerful example of how standardization facilitates interchangeability.

Platform Sharing

Modern vehicle manufacturing often relies heavily on the concept of platform sharing. This involves designing multiple vehicle models around a common underlying architecture, including the chassis, suspension, engine mounts, and often even interior components. Automakers employ this strategy to reduce development costs and streamline production processes. As a result, many parts, particularly those related to the core platform, are directly interchangeable between vehicles built on the same platform, even if they are sold under different brands or trim levels. A good example of platform sharing would be the VAG group of Volkswagen, Audi, Skoda, and SEAT brands. There parts and even complete engines can be directly swappable.

Supplier Commonality

Automotive manufacturers often source components from the same suppliers. For example, Bosch might supply fuel injectors to Ford, BMW, and Toyota. While these injectors may be tuned differently for each specific application, the basic physical dimensions and electrical connectors might be identical, making them potentially interchangeable. This is especially true for components like sensors, switches, and electronic control units (ECUs). Common suppliers are crucial in facilitating interchangeability.

Aftermarket Solutions

The aftermarket industry actively promotes interchangeability by producing universal or adaptable parts designed to fit a wide range of vehicles. This is particularly common for components like air filters, oil filters, brake pads, and universal joints. These aftermarket parts often incorporate adjustable mounting brackets or come with a variety of adapters to ensure compatibility with different vehicles. The aftermarket expands the possiblities of interchangeability even further.

Navigating the Labyrinth: Interchangeability Resources and Considerations

While the potential for parts interchangeability is significant, successfully identifying and utilizing interchangeable components requires careful research and a thorough understanding of the underlying engineering principles. There is no single comprehensive list covering all possible interchanges, as the possibilities are vast and constantly evolving.

Here's a breakdown of valuable resources and crucial considerations:

Parts Catalogs and Online Databases

Reputable auto parts retailers, both online and brick-and-mortar, often maintain extensive parts catalogs that list compatible vehicles for each component. These catalogs are invaluable for identifying potential interchange opportunities. Moreover, several online databases and forums are dedicated to documenting known parts interchanges, often with detailed explanations and user-submitted experiences. Cross-referencing part numbers across different manufacturers is a critical skill in this pursuit.

Vehicle Service Manuals

Vehicle service manuals provide detailed information about the specifications and dimensions of various components. Comparing the specifications of similar components from different vehicles can reveal potential interchangeability. Pay close attention to dimensions, material properties, electrical ratings, and connection types.

Online Forums and Communities

Online forums and communities dedicated to specific vehicle makes and models are often treasure troves of information regarding parts interchangeability. Experienced enthusiasts frequently share their knowledge and experiences, documenting successful (and unsuccessful) interchange attempts. These communities can provide invaluable insights and practical tips.

Important Considerations Before Interchanging

Before attempting to interchange parts, it's crucial to consider the following factors:

- Physical Fit: Will the part physically fit into the intended location? Check dimensions, mounting points, and clearances.

- Functional Compatibility: Will the part perform its intended function correctly in the new application? Consider factors like flow rates, pressure ratings, electrical characteristics, and sensor outputs.

- Safety Implications: Will the interchange compromise safety? This is particularly critical for components like brakes, suspension, and steering systems. Never compromise safety for convenience.

- Legal Compliance: Will the interchange violate any regulations or void warranties? Some modifications may be illegal or affect insurance coverage.

- Long-Term Reliability: Will the interchange affect the long-term reliability of the vehicle? Consider the potential for premature wear or failure due to incompatibility.

- Electronic Compatibility: Modern vehicles rely heavily on electronic control systems. Ensure that the replacement part is compatible with the vehicle's ECU and other electronic components. An incorrectly matched sensor, for instance, can lead to serious performance issues.

Examples of Common Interchange Opportunities

While a comprehensive list is impossible, here are a few common examples of parts interchangeability across different makes and models:

Brake Components

Brake pads and rotors from different manufacturers may be interchangeable if they meet the same specifications and dimensions. Calipers, however, are often more specific to the vehicle model. Always verify brake rotor size, number of lug holes, and caliper mounting distance before swapping.

Filters

Oil filters, air filters, and fuel filters are often interchangeable if they have the same thread size, sealing diameter, and filtration efficiency. Cross-referencing part numbers is essential. Some universal fit kits are available.

Sensors

Sensors like oxygen sensors, mass airflow sensors, and crankshaft position sensors can sometimes be interchanged if they have the same electrical characteristics and connector type. However, calibration and signal output must be carefully considered to avoid performance issues.

Wheels and Tires

Wheels can be interchanged if they have the same bolt pattern, center bore diameter, and offset. Tire sizes can be interchanged within certain limits, but it's crucial to maintain the overall rolling diameter to avoid affecting the speedometer and ABS system.

Engine Components

Engine parts, such as alternators and starters, can be interchanged if they share the same mounting pattern and electrical connections. Spark plugs are highly standardised, but remember heat range is important.

The Future of Interchangeability

As vehicle technology continues to evolve, the landscape of parts interchangeability is also changing. The increasing complexity of electronic systems and the proliferation of proprietary technologies may make interchangeability more challenging in the future. However, the underlying principles of standardization and platform sharing will likely continue to drive some degree of interchangeability. Furthermore, the aftermarket industry will undoubtedly continue to innovate and develop solutions that enhance interchangeability, ensuring that vehicle owners have access to a wider range of parts and repair options. The automotive industry will continue to see a need for easily sourced parts which will promote interchangeability.

In conclusion, while parts interchangeability is not a guaranteed solution, it offers a powerful tool for reducing costs, simplifying repairs, and expanding the possibilities for vehicle modification. By carefully researching and considering the relevant factors, informed individuals can unlock the potential of interchangeable parts and gain a deeper understanding of the intricate world of automotive engineering.