5x114 Bolt Pattern Fits What Cars

Alright, let's talk about 5x114.3 – one of the most common bolt patterns out there. If you're planning on swapping wheels, replacing hubs, or just want to understand more about your vehicle's drivetrain, knowing what cars share this bolt pattern is crucial. This isn't just about aesthetics; it's about safety and ensuring proper fitment. We'll break down the key specs, explain how it works, and give you some real-world tips to avoid common mistakes.

Purpose of Understanding Bolt Patterns

Why bother learning about bolt patterns? Several reasons. First, if you're looking to upgrade your wheels, knowing your bolt pattern lets you shop for compatible options. Second, if you're doing brake work or replacing a hub assembly, you need to know the bolt pattern to order the correct parts. Finally, understanding bolt patterns can help you diagnose wheel vibration issues and ensure your wheels are properly centered on the hub. It's essential for any DIY mechanic or car enthusiast who wants to modify or maintain their vehicle safely and effectively.

Key Specs and Main Parts: The 5x114.3 (or 5x4.5") Bolt Pattern

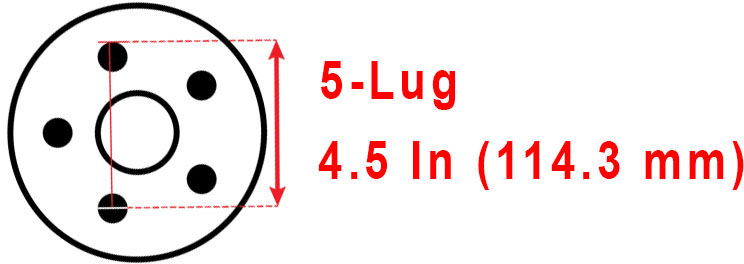

The 5x114.3 bolt pattern (often referred to as 5x4.5" in imperial units) is defined by two numbers: the number of lugs and the diameter of the circle they sit on. Let's break that down:

- Number of Lugs: The '5' in 5x114.3 indicates that the wheel has five lug holes. These are the holes where the lug nuts or bolts attach the wheel to the hub.

- Bolt Circle Diameter (BCD): The '114.3' (or 4.5") refers to the diameter, in millimeters (or inches), of the imaginary circle that passes through the center of each of the five lug holes. This is a crucial measurement, and even a slight difference can prevent a wheel from fitting correctly.

Key components involved include:

- Wheel Hub: The central part of the wheel assembly that rotates and connects to the axle. The wheel hub has studs (or threaded holes) that match the wheel's bolt pattern.

- Wheel Studs (or Bolts): These are the threaded fasteners that protrude from the hub and secure the wheel using lug nuts. Some vehicles use wheel bolts instead of studs, which thread directly into the hub.

- Lug Nuts: These are the fasteners that screw onto the wheel studs to hold the wheel in place. Different lug nut styles exist (conical, ball seat, flat seat), and it's crucial to use the correct type for your wheels.

- Wheel: The rim itself, containing the lug holes arranged in the correct bolt pattern.

- Center Bore: The diameter of the hole in the center of the wheel that centers the wheel on the hub. While not directly part of the bolt pattern specification, a proper center bore match is crucial for vibration-free driving.

How It Works: Ensuring a Proper Fit

The 5x114.3 bolt pattern dictates the precise arrangement of the lug holes on the wheel and the corresponding studs (or holes) on the hub. When a wheel with the correct bolt pattern is placed against the hub, the lug holes should align perfectly with the studs. This allows the lug nuts to be tightened securely, clamping the wheel against the hub and providing a stable and safe connection.

Here's a simplified breakdown:

- The wheel is placed against the hub, aligning the lug holes with the studs.

- Lug nuts are hand-tightened onto the studs, ensuring the wheel is centered on the hub.

- Using a torque wrench, the lug nuts are tightened to the manufacturer's specified torque, ensuring even clamping force across all five studs. Over-tightening can damage the studs or warp the wheel. Under-tightening can cause the wheel to come loose.

Important Note: Using the wrong bolt pattern, even if it seems close, is extremely dangerous. It can cause the wheel to vibrate, damage the studs, and potentially lead to wheel failure and accidents.

Real-World Use and Basic Troubleshooting

Let's say you're trying to fit a set of aftermarket wheels you found online, but you're not sure if they'll fit your car. Here's what you should do:

- Identify Your Vehicle's Bolt Pattern: Consult your owner's manual, a reputable online database (like Wheel-Size.com), or a local tire shop to determine your vehicle's factory bolt pattern.

- Check the Wheel's Bolt Pattern: The wheel's bolt pattern should be stamped or engraved somewhere on the wheel (usually on the back). If not, you can measure it.

- Measuring the Bolt Pattern (5-lug): This can be tricky with 5-lug patterns. Measure from the center of one stud to the outside edge of the stud directly across from it. Then, use a conversion chart or online calculator to determine if that measurement corresponds to 114.3mm (or 4.5"). This method requires accuracy and is best done with calipers.

- Inspect the Center Bore: Ensure the center bore of the wheel is equal to or larger than the center bore of your vehicle's hub. If the wheel's center bore is smaller, it won't fit. If it's larger, you may need hub-centric rings to ensure proper centering.

Common Issues and Solutions:

- Vibration: If you experience vibration after installing new wheels, double-check the lug nut torque, center bore fitment, and ensure the wheels are properly balanced.

- Difficulty Tightening Lug Nuts: This could indicate damaged studs, incorrect lug nut type, or a mismatched bolt pattern. Stop immediately and investigate.

- Stripped Lug Nuts/Studs: Over-tightening or using the wrong lug nut type can strip the threads. Replace damaged studs or lug nuts immediately.

Safety: Risky Components and Precautions

The wheel hub, studs, and lug nuts are critical safety components. Any damage or improper installation can have serious consequences.

- Damaged Studs: Inspect studs for signs of damage, such as stripped threads, cracks, or bending. Replace any damaged studs immediately.

- Incorrect Lug Nuts: Using the wrong lug nut style (e.g., conical seat lug nuts on wheels designed for ball seat lug nuts) can result in improper clamping force and wheel failure. Always use the correct lug nut type for your wheels.

- Over-Tightening Lug Nuts: Over-tightening can stretch the studs, damage the wheel, or even cause the studs to break. Always use a torque wrench and tighten lug nuts to the manufacturer's specified torque.

- Corrosion: Rust and corrosion can weaken studs and lug nuts. Inspect these components regularly and replace them if necessary.

- Wheel Spacers: While wheel spacers can be used to improve wheel fitment, they can also introduce safety risks if not installed correctly or if they are of poor quality. Use only high-quality spacers from reputable manufacturers and follow installation instructions carefully. Extended studs may be required when using thicker spacers.

Always prioritize safety when working on your vehicle's wheels. If you're not comfortable performing any of these tasks, consult a qualified mechanic.

This guide covers the basics of the 5x114.3 bolt pattern. Remember to always double-check your vehicle's specifications and consult with a professional if you have any doubts. We hope this helps you navigate the world of wheels and tires with confidence.

We have a detailed diagram illustrating the 5x114.3 bolt pattern, including precise measurements and angles. It's available for download. This visual aid can be a valuable resource for visualizing the specifications and ensuring accurate measurements when working on your wheels.