All Wheel Drive How Does It Work

All-wheel drive (AWD) systems have become increasingly common, offering enhanced traction and stability in various driving conditions. Whether you're considering modifying your vehicle, tackling a repair, or simply expanding your automotive knowledge, understanding how AWD systems function is essential. This article will break down the key components, operational principles, and troubleshooting tips, allowing you to confidently diagnose and potentially address issues with your AWD system. We also have a detailed diagram available for download to help you visualize the system. This diagram is crucial for understanding the layout of your specific AWD system and can be a valuable resource when performing repairs or upgrades.

Key Specs and Main Parts

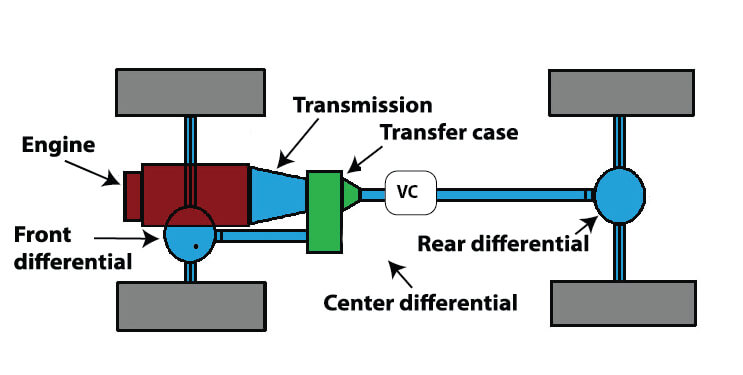

AWD systems vary significantly depending on the manufacturer and vehicle type. However, some core components are consistent across most designs. Let's delve into the essential parts and their roles:

- Engine: The source of power, obviously. The engine's torque is what the AWD system distributes.

- Transmission: Transmits the engine's power to the drivetrain. In an AWD vehicle, the transmission is often beefier to handle the increased stress.

- Transfer Case: This is the heart of most AWD systems. The transfer case splits the engine's torque and directs it to both the front and rear axles. It may be gear-driven, chain-driven, or use a viscous coupling or clutch pack. Some transfer cases offer a low-range gear for off-road applications, providing increased torque at lower speeds.

- Front and Rear Differentials: Differentials allow the wheels on each axle to rotate at different speeds, which is necessary when turning. In an AWD system, both axles have differentials. Open differentials send torque to the wheel with the least resistance, which can be a problem in slippery conditions.

- Center Differential (or Coupling): This component is located between the front and rear axles. It allows for speed differences between the front and rear driveshafts. Without a center differential (or coupling), the drivetrain would bind up and potentially break when driving on pavement. Different types of center differentials and couplings exist, including viscous couplings, clutch packs, and electronic control units.

- Driveshafts (Propeller Shafts): These rotating shafts transmit power from the transfer case to the front and rear differentials. They must be strong and balanced to handle the high speeds and torque involved.

- Axle Shafts: These shafts transmit power from the differentials to the wheels.

- Wheel Hubs and Bearings: The interface where the axle connects to the wheel, enabling rotation.

- Electronic Control Unit (ECU): In many modern AWD systems, an ECU monitors various sensors (wheel speed, throttle position, steering angle) and adjusts the torque distribution between the front and rear axles to optimize traction and stability.

Key Specs to Consider: Torque split (e.g., 50/50, variable), response time of the AWD system, type of center differential/coupling, and whether the system is full-time or part-time.

Symbols Explained

Understanding the symbols on an AWD system diagram is vital for proper diagnosis. Here's a breakdown of common symbols:

- Solid Lines: Typically represent mechanical connections, such as shafts, gears, and linkages.

- Dashed Lines: Often indicate hydraulic or pneumatic lines, such as those used in electronically controlled couplings or differentials.

- Dotted Lines: Usually represent electrical wiring or communication buses (e.g., CAN bus) used to transmit signals between sensors, ECUs, and actuators.

- Arrows: Indicate the direction of power flow or fluid flow.

- Color Coding: Some diagrams use color coding to differentiate between different types of fluids or systems. For example, blue might represent hydraulic fluid, while green represents coolant.

- Specific Component Icons: Each component (e.g., differential, transfer case, pump, sensor) will have a unique icon, often standardized across diagrams. Consult the diagram's legend for a complete list.

How It Works

The basic principle of AWD is simple: distribute engine torque to all four wheels. However, the implementation varies widely. Let's explore the different types of AWD systems:

- Full-Time AWD: In a full-time AWD system, all four wheels are constantly driven. These systems typically use a center differential (or equivalent) to allow for speed differences between the front and rear axles. This ensures smooth operation on pavement without drivetrain binding.

- Part-Time AWD: Part-time AWD systems are typically found in older vehicles or those designed for serious off-roading. They do not have a center differential and should only be engaged on slippery surfaces (e.g., snow, mud, gravel). Driving in part-time AWD mode on dry pavement can cause significant drivetrain damage due to binding.

- Automatic AWD (On-Demand AWD): These systems primarily operate in two-wheel drive (usually front-wheel drive) until wheel slippage is detected. When slippage occurs, a coupling (viscous coupling, clutch pack, or electronically controlled unit) engages to transfer torque to the other axle. These systems offer a balance between fuel efficiency and traction.

Torque Distribution: The way torque is distributed between the front and rear axles is critical. Some systems have a fixed torque split (e.g., 50/50), while others have a variable torque split that can be adjusted based on driving conditions. Electronically controlled AWD systems can use sensors and algorithms to optimize torque distribution for maximum traction and stability.

Example: Consider an automatic AWD system using an electronically controlled clutch pack. The ECU monitors wheel speed sensors. If the front wheels begin to slip, the ECU commands the clutch pack to engage, transferring torque to the rear wheels. The amount of torque transferred is proportional to the amount of wheel slippage.

Real-World Use: Basic Troubleshooting Tips

Here are some common problems and troubleshooting tips for AWD systems:

- Unusual Noises: Grinding, clicking, or whining noises can indicate problems with the transfer case, differentials, or driveshafts. Inspect these components for damage or wear.

- Vibrations: Vibrations, especially at higher speeds, can be caused by unbalanced driveshafts or worn U-joints. Have the driveshafts professionally balanced if necessary.

- AWD Warning Light: If the AWD warning light illuminates, there is likely a problem with the system. Use an OBD-II scanner to retrieve diagnostic trouble codes (DTCs) and consult a repair manual for troubleshooting steps.

- Poor Traction: If you're experiencing poor traction in slippery conditions, check the condition of your tires. Also, ensure that the AWD system is properly engaged (if it's a part-time system). If the problem persists, there may be an issue with the transfer case, differentials, or couplings.

- Fluid Leaks: Check for fluid leaks around the transfer case, differentials, and couplings. Low fluid levels can cause damage to these components.

Quick Checks: Before diving into complex repairs, check the fluid levels in the transfer case and differentials. Also, inspect the driveshafts and U-joints for signs of damage or wear.

Safety

Working on AWD systems can be dangerous if proper precautions are not taken. Here are some safety tips:

- Disconnect the Battery: Always disconnect the negative battery cable before working on electrical components.

- Support the Vehicle Properly: Use jack stands to support the vehicle securely before working underneath it. Never rely solely on a jack.

- Wear Safety Glasses: Protect your eyes from flying debris.

- Use Proper Tools: Use the correct tools for the job to avoid damaging components or injuring yourself.

- Be Careful with Fluids: Some fluids, such as gear oil, can be harmful if ingested or come into contact with skin. Wear gloves and eye protection when handling fluids.

- High-Pressure Components: Be extremely cautious when working around high-pressure hydraulic systems. These systems can cause serious injury if mishandled.

Risky Components: The transfer case and differentials contain complex gears and bearings that can be damaged if disassembled incorrectly. The electronically controlled couplings can also be challenging to diagnose and repair without specialized tools and knowledge. Always consult a repair manual or seek professional assistance if you are unsure about any procedure.

To further aid your understanding, we have the detailed AWD system diagram mentioned earlier available for download. This diagram will provide a visual representation of the system layout and component interconnections. Use this resource in conjunction with the information presented in this article to enhance your troubleshooting and repair skills.