All Wheel Drive What Does It Mean

Alright, let's dive deep into All-Wheel Drive (AWD) systems. As an experienced DIYer, understanding the ins and outs of your vehicle's drivetrain is crucial for effective maintenance, troubleshooting, and even some performance modifications. This article will give you a solid technical foundation on AWD systems, empowering you to tackle more complex tasks with confidence.

Purpose

Understanding AWD systems matters for several reasons. First, it allows you to properly diagnose issues. Is that weird vibration related to a failing center differential, or is it just a worn CV joint? Knowledge is power. Second, it enables you to perform preventative maintenance effectively. Knowing which parts are crucial and how they interact allows you to inspect and service them proactively. Third, if you're considering modifying your vehicle for off-road or performance applications, understanding the AWD system is paramount to avoid damaging components or creating unintended consequences. And lastly, it lets you discuss repairs more intelligently with your mechanic, ensuring you get the right service at the right price.

Key Specs and Main Parts

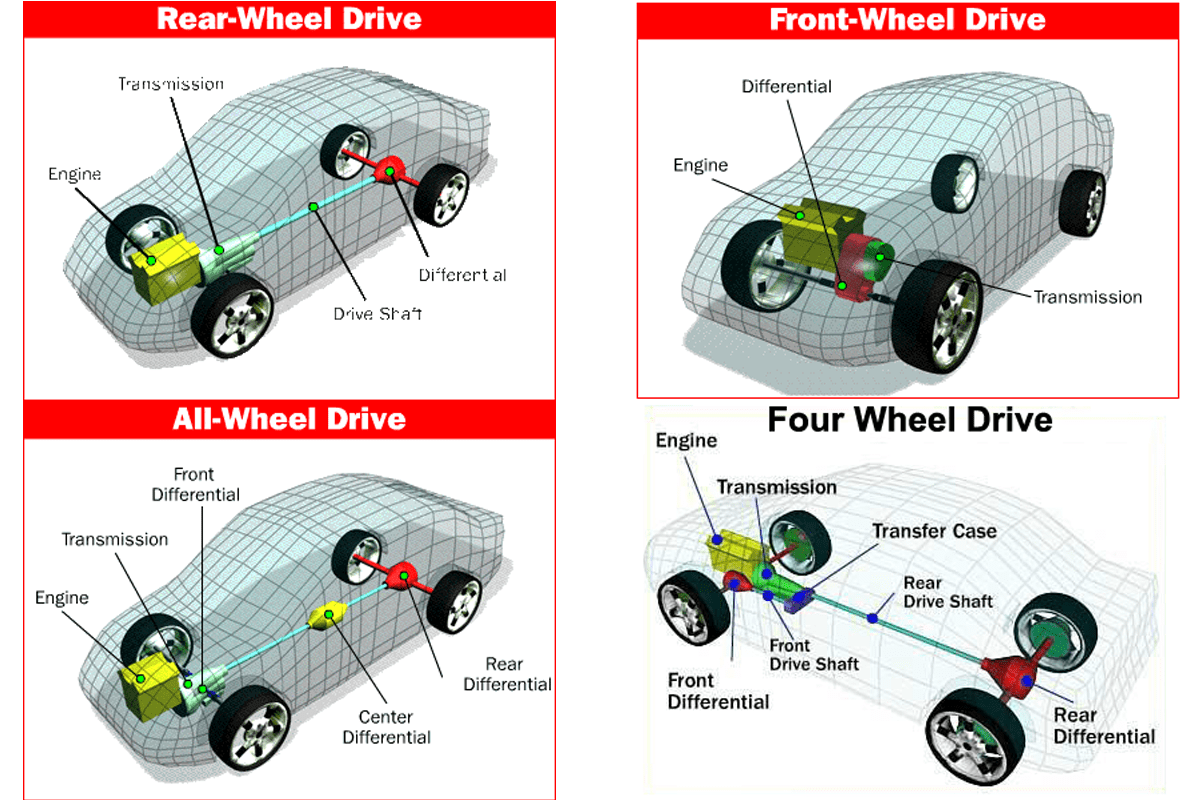

AWD systems come in a variety of flavors, but they all share a common goal: to deliver torque to all four wheels. The key difference lies in how they achieve this. Let's break down the main components:

- Engine: The source of power, obviously.

- Transmission: Converts the engine's power into usable torque and sends it to the drivetrain.

- Transfer Case (or Center Differential): This is the heart of the AWD system. It splits the torque between the front and rear axles. Depending on the system, this split can be fixed, variable, or on-demand.

- Front Differential: Distributes torque between the front wheels.

- Rear Differential: Distributes torque between the rear wheels. Many AWD systems utilize limited-slip or electronically controlled differentials for enhanced traction.

- Driveshafts (or Propeller Shafts): Connect the transfer case to the front and rear differentials.

- Axle Shafts: Connect the differentials to the wheels.

- CV Joints (Constant Velocity Joints): Allow the axles to articulate as the suspension moves, ensuring smooth power delivery.

- Wheel Speed Sensors: Provide data to the AWD control unit, which can be used to adjust torque distribution in some systems.

- AWD Control Unit (ECU): Manages the operation of electronically controlled AWD systems, making decisions based on sensor data.

Key Specs to consider include:

- Torque Split (Front/Rear): The percentage of torque sent to each axle. For example, a 50/50 split means equal torque to both axles.

- Type of Transfer Case: (e.g., viscous coupling, Torsen differential, electronically controlled clutch pack).

- Type of Differentials: (e.g., open, limited-slip, locking).

- Response Time: For on-demand systems, how quickly the AWD system engages.

How It Works

The fundamental principle of AWD is simple: by driving all four wheels, you increase the available traction. This is especially beneficial in slippery conditions or when accelerating aggressively. However, the execution can vary considerably.

Let's consider a few common types of AWD systems:

- Permanent AWD (Full-Time AWD): These systems continuously send power to all four wheels. They often use a center differential (like a Torsen or planetary gear set) to allow for different wheel speeds between the front and rear axles. This is crucial for driving on pavement, as the front and rear wheels travel different distances when turning. Without a center differential, the drivetrain would bind and potentially damage components.

- Part-Time AWD: Typically found in older trucks and SUVs, these systems lock the front and rear axles together, providing maximum traction in off-road conditions. However, they must not be used on pavement, as the lack of a center differential will cause driveline binding and damage.

- On-Demand AWD (Automatic AWD): These systems normally operate in two-wheel drive (usually front-wheel drive) to improve fuel economy. When the system detects wheel slip, it automatically engages the rear axle, providing AWD capability. This engagement is typically achieved using a viscous coupling, a multi-plate clutch pack (electronically controlled), or a similar mechanism. The AWD control unit monitors wheel speed sensors and other parameters to determine when to activate the rear axle.

The transfer case is the critical component that dictates how torque is split and managed. In permanent AWD systems, the center differential allows for torque biasing, sending more power to the axle with the most traction. In on-demand systems, the transfer case acts as an engagement mechanism, routing power to the rear axle only when needed.

Real-World Use - Basic Troubleshooting Tips

Here are some basic troubleshooting tips for AWD systems:

- Vibrations: Vibrations, especially at certain speeds, can indicate problems with driveshafts, CV joints, or the transfer case. Inspect these components for wear, damage, or loose connections.

- Noises: Grinding, whining, or clunking noises can point to issues with differentials, bearings, or the transfer case. Identify the source of the noise as precisely as possible.

- AWD Light On: If the AWD warning light illuminates, it indicates a fault in the system. This could be a sensor issue, a problem with the AWD control unit, or a mechanical failure. Have the system scanned for diagnostic trouble codes (DTCs) to pinpoint the problem.

- Uneven Tire Wear: Excessive or uneven tire wear can indicate a misalignment issue or a problem with the differentials. Ensure proper tire inflation and alignment. If the issue persists, investigate the differentials.

- Difficulty Turning: If you experience excessive driveline binding or difficulty turning, especially in part-time AWD systems on pavement, disengage the AWD system immediately to avoid damage.

Quick Checks:

- Check fluid levels in the transfer case and differentials. Low fluid levels can lead to component failure.

- Visually inspect CV boots for tears or leaks. Damaged CV boots can allow contaminants to enter the joints, causing premature wear.

- Listen for unusual noises while turning sharply at low speeds. This can help identify differential issues.

Safety

Working on AWD systems can be inherently risky. Here are a few key safety points to remember:

- Driveline Binding: As mentioned before, forcing a part-time AWD system on pavement can cause severe driveline binding, potentially leading to component failure and even accidents. Always disengage the AWD system on pavement.

- High-Pressure Fluids: Automatic transmissions and some transfer cases operate with high-pressure fluids. Use caution when disconnecting lines or components.

- Heavy Components: Differentials, transfer cases, and driveshafts are heavy and awkward to handle. Use proper lifting equipment and support them securely.

- Rotating Parts: Never work on the AWD system with the engine running or the wheels in motion. Always disconnect the battery before working on any electrical components.

- Proper Support: Never rely solely on a jack to support a vehicle. Always use jack stands placed on solid points of the frame.

Remember, if you're unsure about any aspect of the repair or maintenance process, consult a qualified mechanic. It's always better to be safe than sorry.

By understanding the components, operation, and potential issues of your AWD system, you're well-equipped to handle many common repairs and maintenance tasks. This knowledge not only saves you money but also empowers you to keep your vehicle running smoothly and safely.