Awd Cars What Does It Mean

Alright, let's dive into the world of All-Wheel Drive (AWD) systems. If you're a DIY enthusiast or someone who likes to understand the nuts and bolts of their vehicle, knowing how AWD works is crucial. This knowledge can be invaluable for diagnostics, repairs, and even making informed decisions about modifications. This isn't just about knowing you have AWD; it's about understanding how that power gets distributed and what components make it happen.

Key Specs and Main Parts

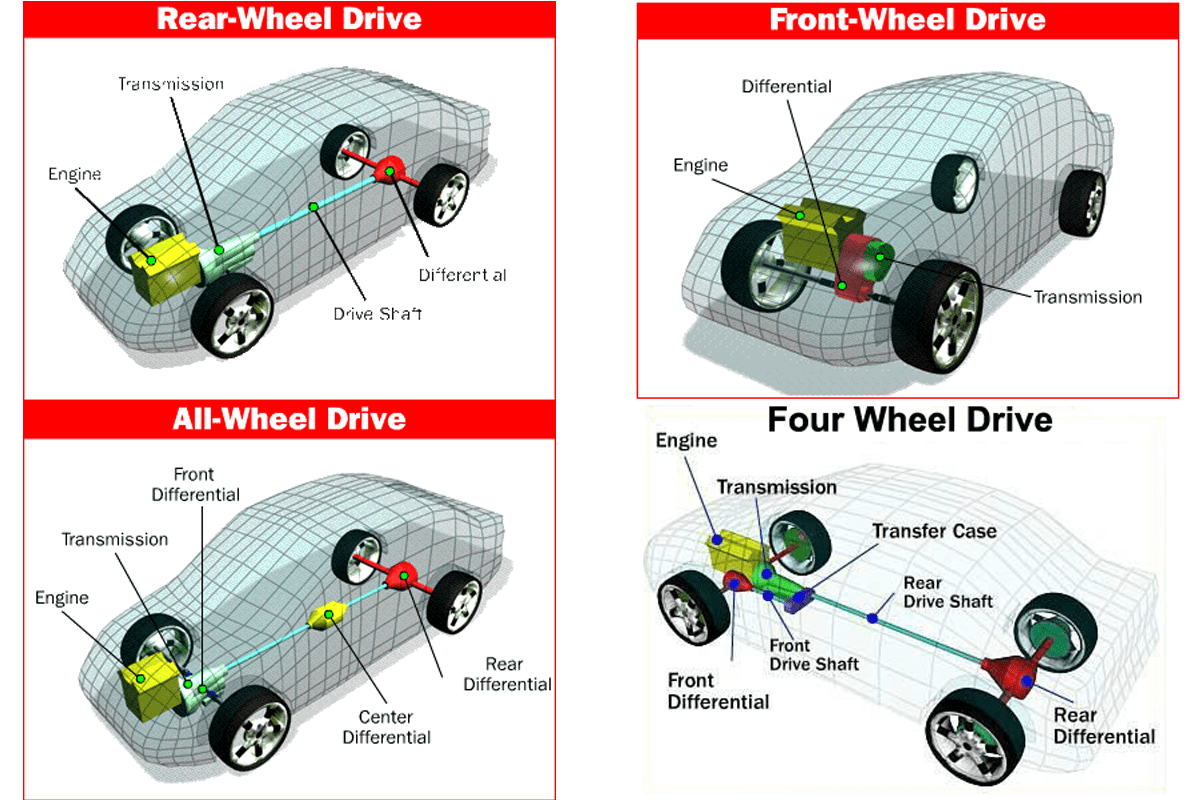

AWD systems come in many flavors, but they all share the same core purpose: to deliver torque to all four wheels. Unlike a traditional 4x4 system, which often requires manual engagement and is designed primarily for off-road use, AWD systems are typically active full-time or part-time and can be used effectively on paved roads. Here's a breakdown of the key components:

- Engine: The source of the power, obviously. The engine's torque output is the foundation of the entire system.

- Transmission: This component takes the engine's power and transmits it, usually with gear ratios, to the rest of the drivetrain. For AWD applications, the transmission needs to be configured to send power towards both the front and rear axles.

- Transfer Case: This is a critical component that splits power from the transmission to both the front and rear driveshafts. It's essentially a secondary gearbox. Some transfer cases have low-range gearing for serious off-roading, while others are simpler and focus on on-road performance. A viscous coupling or electronically controlled clutch pack might be integrated into the transfer case to regulate torque distribution.

- Front and Rear Driveshafts: These rotating shafts transmit the torque from the transfer case to the differentials. They have universal joints (U-joints) or constant-velocity (CV) joints to allow for suspension movement and changes in driveline angles.

- Front and Rear Differentials: These are gearsets that allow each wheel on an axle to spin at different speeds, which is essential when turning. Open differentials are standard, but limited-slip differentials (LSDs) or electronic locking differentials can provide better traction by limiting wheelspin on one side.

- Axles and Wheels: Finally, the axles transmit the torque from the differentials to the wheels.

- Control Unit (ECU/TCU): Many modern AWD systems are electronically controlled. An ECU or TCU monitors wheel speeds, throttle position, steering angle, and other parameters to dynamically adjust torque distribution. This adds layers of complexity and sophistication to AWD systems.

How It Works

The basic principle is to distribute engine torque to all four wheels, providing better traction in slippery or low-grip conditions. Here's a simplified explanation of how a typical electronically controlled AWD system works:

- The engine generates torque, which is then sent to the transmission.

- The transmission directs power to the transfer case.

- The transfer case splits the power between the front and rear driveshafts. The split is not always 50/50; it can vary depending on the system's design and operating conditions. For example, a system might default to a 90/10 split in dry conditions for better fuel economy, then shift to a 50/50 split when wheel slip is detected.

- The driveshafts transmit the power to the front and rear differentials.

- The differentials allow each wheel to spin at different speeds during turns.

- If one wheel starts to slip (e.g., on ice), the system detects the wheelspin and can react in several ways. An open differential will send all the torque to the wheel with the least resistance. However, an LSD or electronically controlled system will try to limit the wheelspin by transferring torque to the wheels with more grip.

- The ECU/TCU constantly monitors sensor data and adjusts the torque distribution based on the current driving conditions. This can involve activating clutches in the transfer case, applying brakes to individual wheels (brake-based torque vectoring), or adjusting engine power.

Real-World Use – Basic Troubleshooting Tips

Understanding how your AWD system works can help you diagnose potential issues. Here are a few common problems and troubleshooting tips:

- Noise: Unusual noises, such as whining, grinding, or clunking, can indicate problems with the transfer case, differentials, or driveshafts. Check the fluid levels in the transfer case and differentials. Low fluid levels or contaminated fluid can cause serious damage.

- Vibrations: Vibrations, especially at higher speeds, can be caused by worn U-joints or CV joints on the driveshafts. Inspect the joints for play and grease leaks.

- Reduced Traction: If you notice a significant decrease in traction in slippery conditions, it could indicate a problem with the transfer case, differentials, or electronic control system. Check for any error codes stored in the ECU/TCU. Also ensure that all tires are the same size and have similar tread depth. Mismatched tires can cause excessive wear on the AWD system components.

- AWD Indicator Light: If your vehicle has an AWD indicator light, pay attention to it. If the light comes on, it indicates a problem with the AWD system. Consult your owner's manual or a repair manual for specific diagnostic procedures.

Safety – Highlight Risky Components

Working on AWD systems can be dangerous if you're not careful. Here are a few safety precautions:

- Driveline Components Under Load: Never work on the driveline while the engine is running or the vehicle is in gear. Make sure the vehicle is properly supported on jack stands and the wheels are blocked.

- High-Pressure Fluids: Be careful when working with hydraulic systems, such as those found in some electronically controlled clutch packs. These systems can contain high-pressure fluids that can cause serious injury if not handled properly.

- Electrical Systems: Disconnect the battery before working on any electrical components.

- Torque Specifications: Always use a torque wrench to tighten bolts to the specified torque. Overtightening or undertightening bolts can lead to component failure.

When working on AWD systems, specifically concerning the transfer case and differentials, always ensure that the vehicle is safely secured, and you're wearing appropriate personal protective equipment (PPE). Furthermore, disposing of used fluids properly is imperative to protect the environment. Consult local regulations for guidance on used oil and fluid disposal.

Symbols and Lines Explained

Schematic diagrams for AWD systems typically use standard automotive symbols. Here’s a quick guide:

- Solid Lines: Represent mechanical connections (e.g., driveshafts).

- Dashed Lines: Represent electrical connections or vacuum lines.

- Boxes: Typically represent components like the transfer case, differentials, or the ECU.

- Circles: Can represent sensors or actuators.

- Arrows: Indicate the direction of power flow or fluid flow.

- Color Coding: Often used to differentiate between different systems or circuits (e.g., red for power, black for ground).

Deciphering these symbols, in combination with the system diagram, allows for tracing the system's path and diagnosing potential failures.

Hopefully, this overview has given you a solid foundation for understanding AWD systems. Remember, this is a complex topic, and there's always more to learn. With a bit of study and some hands-on experience, you'll be well on your way to becoming an AWD expert!