How Do Electric Car Motors Work

So, you're ready to dive into the heart of an electric vehicle (EV): the electric motor. Unlike internal combustion engines (ICE), EVs rely on these marvels of engineering to convert electrical energy into motion. Understanding how they work isn't just about satisfying curiosity; it's crucial for troubleshooting, performing basic repairs, and even for those ambitious modders looking to optimize their EV's performance. We're going to break down the workings of a typical EV motor, focusing on a Permanent Magnet Synchronous Motor (PMSM), which is a common type in modern electric cars.

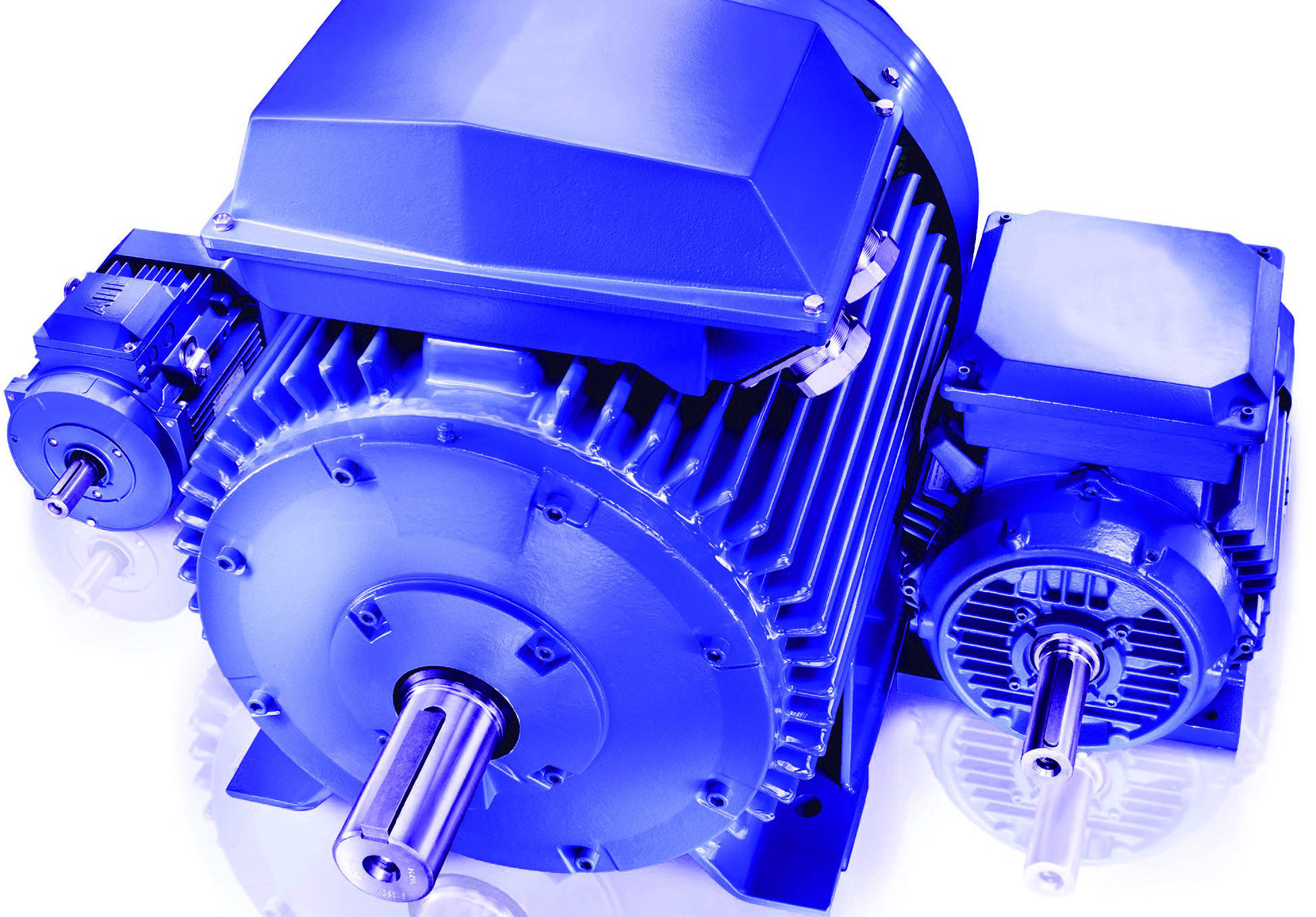

Key Specs and Main Parts

Before we get into the nitty-gritty, let's define some key components and specifications. Understanding these will make deciphering diagrams and troubleshooting issues much easier.

- Stator: The stationary part of the motor. It contains the windings that create a rotating magnetic field when energized.

- Rotor: The rotating part of the motor. In a PMSM, it houses permanent magnets.

- Windings: Coils of wire (typically copper) wrapped around the stator core. These carry the electrical current that generates the magnetic field.

- Permanent Magnets: High-strength magnets (usually made of rare-earth materials like neodymium) embedded in the rotor. These interact with the stator's magnetic field to produce torque.

- Inverter: An electronic device that converts DC (Direct Current) power from the battery into AC (Alternating Current) power needed by the motor. It also controls the frequency and voltage of the AC power, thereby controlling the motor's speed and torque.

- Resolver/Encoder: A sensor that provides feedback on the rotor's position and speed. This information is critical for the inverter to precisely control the motor.

- Cooling System: EVs generate heat, and the motor is a major source. Cooling systems, often liquid-cooled, are essential to maintain optimal operating temperatures and prevent damage.

Key specifications to keep in mind include:

- Voltage (V): The electrical potential difference applied to the motor. Higher voltage generally allows for higher power output. Common EV voltages range from 400V to 800V.

- Current (A): The flow of electrical charge through the motor windings. Higher current equates to higher torque, up to a point.

- Power (kW or hp): The rate at which the motor performs work. It is directly related to voltage and current (Power = Voltage x Current).

- Torque (Nm or lb-ft): The rotational force produced by the motor. This is what accelerates the car.

- Speed (RPM): The rotational speed of the motor, measured in revolutions per minute.

- Efficiency (%): The ratio of mechanical power output to electrical power input. A higher efficiency means less energy is wasted as heat.

Symbols: Lines, Colors, and Icons

Understanding the symbols in an electrical diagram is crucial for troubleshooting and modification. Here's a breakdown of common symbols:

- Solid Lines: Represent electrical conductors (wires). The thickness of the line doesn't typically indicate wire gauge.

- Dashed Lines: Often represent communication lines (e.g., CAN bus) or mechanical linkages.

- Colored Wires: Colors are standardized to indicate the function of the wire. Black is typically ground, red is often positive DC, and other colors are used for specific signals or phases of AC power.

- Ground Symbol (┴): Indicates a connection to the electrical ground.

- Voltage Source (+/ -): Shows the source of electrical power.

- Motor Symbol (M inside a circle): Represents the electric motor.

- Resistor Symbol (Zigzag Line): Represents resistance in the circuit.

- Capacitor Symbol (Two Parallel Lines): Represents a capacitor, which stores electrical energy.

- Inductor Symbol (Coiled Line): Represents an inductor, which opposes changes in current.

- Diode Symbol (Triangle Pointing at a Line): Represents a diode, which allows current to flow in only one direction.

- Transistor Symbol (Various): Represents a transistor, which acts as an electronic switch or amplifier.

How It Works: From Battery to Motion

Let's walk through the process of how an EV motor converts electrical energy into motion. We'll focus on a Permanent Magnet Synchronous Motor (PMSM):

- DC Power from the Battery: The process begins with the battery pack, which provides DC power at a specific voltage (e.g., 400V).

- Inverter Conversion: The inverter is the crucial link between the DC battery and the AC motor. It takes the DC voltage and converts it into three-phase AC voltage. Three-phase power provides a smoother and more efficient energy delivery compared to single-phase. The inverter uses sophisticated switching techniques (often employing Insulated Gate Bipolar Transistors or IGBTs) to create this AC waveform. Crucially, the inverter controls both the frequency and amplitude (voltage) of the AC signal.

- Rotating Magnetic Field: The three-phase AC current flows through the stator windings. The specific arrangement of these windings creates a rotating magnetic field. Think of it like three electromagnets whose strength is constantly changing in a coordinated way, causing a magnetic field that appears to spin around the stator.

- Interaction with Permanent Magnets: The rotor, which contains the permanent magnets, is placed within this rotating magnetic field. The magnets are attracted to the opposite poles of the rotating field.

- Torque and Rotation: The magnetic attraction between the stator's rotating field and the rotor's permanent magnets creates torque, which is the rotational force. The rotor "chases" the rotating magnetic field, causing it to spin. The motor's speed is synchronized with the frequency of the AC current supplied by the inverter (hence the name "synchronous" motor).

- Resolver/Encoder Feedback: The resolver or encoder continuously monitors the rotor's position and speed. This information is fed back to the inverter.

- Closed-Loop Control: The inverter uses this feedback to precisely control the frequency and voltage of the AC power, ensuring smooth and efficient operation across a wide range of speeds and loads. This closed-loop control system is what allows for precise throttle control and regenerative braking.

Real-World Use: Basic Troubleshooting Tips

While a full motor overhaul is often best left to professionals, there are some basic troubleshooting steps you can take:

- Check Error Codes: Modern EVs have sophisticated diagnostic systems. Use an OBD-II scanner (if compatible) or the vehicle's built-in diagnostics to check for error codes related to the motor or inverter.

- Inspect Wiring and Connections: Loose or corroded connections can cause a variety of problems. Carefully inspect all wiring and connectors related to the motor, inverter, and resolver/encoder. Look for signs of damage or corrosion.

- Monitor Motor Temperature: Overheating can indicate a problem with the cooling system or excessive load. Use an infrared thermometer to check the motor's temperature after a drive. Compare it to the vehicle's specifications.

- Listen for Unusual Noises: Unusual noises, such as whining, grinding, or clicking, can indicate bearing problems or other mechanical issues within the motor.

- Battery Voltage: Ensure your battery pack is in good health. Low voltage can affect motor performance.

Safety: Risky Components

Working on electric vehicle components can be extremely dangerous due to the high voltages involved. Always adhere to the following safety precautions:

- High Voltage Awareness: EV batteries and inverters operate at very high voltages (hundreds of volts). Even after the car is turned off, these components can retain a dangerous charge.

- Disconnect the Battery: Always disconnect the high-voltage battery pack before working on any electrical components. Follow the manufacturer's recommended procedure for disconnecting the battery, as it may involve specific steps to safely discharge the system.

- Use Insulated Tools: Always use insulated tools rated for high-voltage applications.

- Wear Insulating Gloves and Eye Protection: Wear appropriate personal protective equipment (PPE), including insulated gloves and eye protection.

- Never Work Alone: Always have someone nearby who can assist in case of an emergency.

- Consult the Service Manual: Always refer to the vehicle's service manual for specific instructions and safety precautions.

- Capacitor Discharge: Be aware that capacitors within the inverter can store a dangerous charge even after the battery is disconnected. Allow sufficient time for these capacitors to discharge (usually specified in the service manual) before touching any inverter components.

Remember, if you are uncomfortable or unsure about any aspect of working on your EV's motor, it is always best to consult a qualified EV technician. These systems are complex and potentially dangerous.

To help you further, we have a detailed diagram illustrating the components and operation of a PMSM. This diagram includes annotations and key specifications to aid in your understanding. This file is available for download; please use it responsibly and always prioritize safety.