How Do I Build An Electric Car

So, you want to build an electric car, huh? That's a serious undertaking, but definitely achievable with the right knowledge and preparation. Think of this article as your comprehensive, if slightly condensed, workshop manual. We'll be covering the essential components, how they interact, and some real-world considerations to get you started. This isn't a plug-and-play project, but with patience and attention to detail, you can electrify your ride. For those of you eager to get hands-on right away, we can also provide you with detailed schematics and diagrams which you can download upon request.

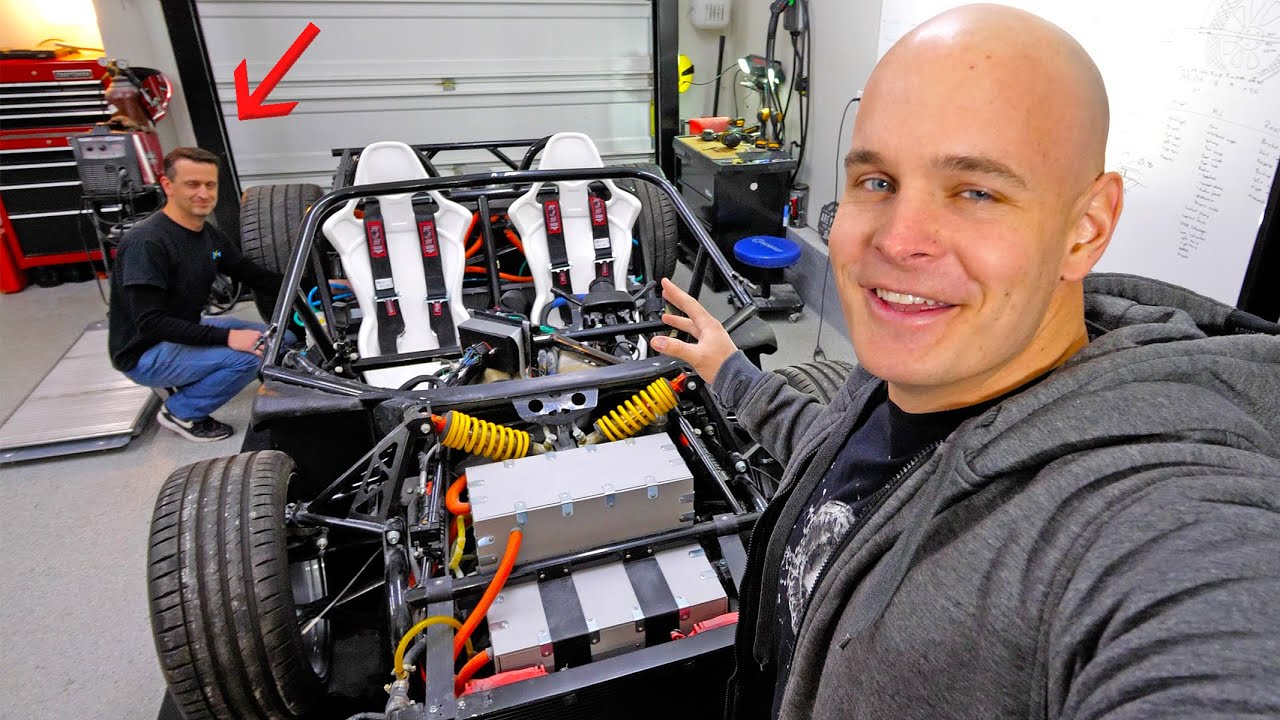

Key Specs and Main Parts

Before we dive deep, let's define the core components of an electric vehicle (EV) conversion or build. Understanding these parts and their functions is critical for a successful project.

- Battery Pack: The heart of your EV. This is a collection of individual battery cells (usually lithium-ion, but other chemistries like LFP are also common) connected in series and parallel to achieve the desired voltage and capacity. Capacity is measured in kilowatt-hours (kWh) and determines your range. Voltage is critical for matching your motor and controller.

- Electric Motor: This replaces the internal combustion engine (ICE). Common types include AC induction motors (ACIM) and permanent magnet synchronous motors (PMSM). Power is measured in kilowatts (kW) and determines your acceleration and top speed.

- Motor Controller (Inverter): This is the brain of the operation. It takes DC power from the battery pack and converts it into AC power to drive the motor. It also controls the motor's speed and torque based on your throttle input. Choosing the right controller that is compatible with your motor and battery voltage is essential.

- Battery Management System (BMS): This vital component monitors the health of individual battery cells, prevents overcharging and over-discharging, and balances the cell voltages to maximize battery life. A good BMS is non-negotiable.

- Charger: This device plugs into an AC power outlet (or a DC fast charger) and converts the AC voltage into DC voltage to charge the battery pack. Onboard chargers are integrated into the vehicle, while offboard chargers are separate units.

- DC-DC Converter: This converts the high voltage DC from the battery pack to a lower voltage (typically 12V) to power the vehicle's auxiliary systems, such as lights, wipers, and the infotainment system.

- Wiring Harness: A collection of wires and connectors that connect all the components together. Proper wiring is crucial for safety and reliability.

- Throttle Pedal (Accelerator): Sends a signal to the motor controller to control the speed of the motor.

- Cooling System: Electric motors and controllers generate heat, especially under heavy load. A cooling system, typically using liquid coolant and a radiator, is essential to prevent overheating.

How It Works

Let's break down the flow of electricity in a simplified EV system:

- When you press the accelerator pedal, it sends a signal to the motor controller.

- The motor controller requests power from the battery pack via the BMS.

- The BMS monitors the battery pack's state of charge and health, and allows power to flow if all parameters are within safe limits.

- The motor controller converts the DC power from the battery pack into AC power and sends it to the electric motor.

- The electric motor converts the electrical energy into mechanical energy, which drives the wheels through a transmission or direct drive system.

- During braking, the motor can act as a generator, converting kinetic energy back into electrical energy and storing it in the battery pack (regenerative braking).

- The DC-DC converter takes the high voltage DC from the battery and convert it to 12V to power the auxiliary systems.

Real-World Use – Basic Troubleshooting Tips

Even with careful planning, problems can arise. Here are some common issues and basic troubleshooting steps:

- Car won't start:

- Check the main battery pack disconnect switch.

- Verify the BMS is not reporting any errors (over-voltage, under-voltage, over-temperature).

- Check the motor controller for error codes.

- Inspect the wiring harness for loose connections or damaged wires.

- Limited range:

- Check the battery pack's state of health (SOH). Batteries degrade over time.

- Ensure tires are properly inflated.

- Avoid aggressive driving (acceleration and braking).

- Inspect the BMS for cell imbalances.

- Motor overheating:

- Check the coolant level in the cooling system.

- Inspect the cooling system pump for proper operation.

- Clean the radiator fins to ensure proper airflow.

Remember: Always consult the manufacturer's documentation for your specific components for detailed troubleshooting procedures.

Safety – Highlight Risky Components

Working with high-voltage electricity is inherently dangerous. Always follow these safety precautions:

- High Voltage: The battery pack operates at high voltage (typically hundreds of volts). This voltage can be lethal. Always disconnect the battery pack and discharge any residual voltage before working on the electrical system.

- Insulation: Use proper high-voltage insulated tools and wear appropriate personal protective equipment (PPE), including gloves and safety glasses.

- Grounding: Properly ground all electrical components to prevent electrical shocks.

- Lockout/Tagout: Implement a lockout/tagout procedure to prevent accidental energization of the system while working on it.

- BMS Failures: A malfunctioning BMS can lead to battery fires or explosions. Regularly monitor the BMS for errors and address them promptly.

- Capacitors: Motor controllers often contain large capacitors that can store a significant amount of energy even after the power is disconnected. Discharge these capacitors before working on the controller.

Warning: If you are not comfortable working with high-voltage electricity, seek assistance from a qualified electrician or EV technician.

Symbols – Understanding Electrical Schematics

Understanding electrical schematics is paramount for building and maintaining an EV. Here's a brief overview of common symbols:

- Solid Lines: Represent wires or conductors carrying electrical current.

- Dashed Lines: Often indicate shielding or communication lines (e.g., CAN bus).

- Circles: Can represent various components depending on what's inside of them. A circle with a line through it is commonly a resistor.

- Rectangles: Often represent electronic components like relays or integrated circuits.

- Triangles: Can represent diodes or transistors.

- Ground Symbol: Indicates a connection to ground (earth).

- Battery Symbol: Represents the battery pack. The number of lines indicates the number of cells connected in series.

- Fuse Symbol: Indicates a fuse, which protects the circuit from overcurrent.

- Switch Symbol: Indicates a switch, which can open or close a circuit.

Colors are also important. Typically:

- Red: Positive voltage (e.g., battery positive).

- Black: Negative voltage (e.g., battery negative or ground).

- Blue/Green: Communication lines (e.g., CAN bus).

- Yellow: Switched power (e.g., power from the ignition switch).

Always refer to the specific schematic's legend for a complete list of symbols and their meanings.

Conclusion

Building an electric car is a complex but rewarding project. By understanding the key components, how they interact, and the associated safety considerations, you can successfully electrify your ride. Remember to start with a well-defined plan, research your components thoroughly, and prioritize safety at all times. Don't be afraid to ask for help from the EV community – there are plenty of experienced builders who are willing to share their knowledge. Finally, remember that we have detailed schematics and diagrams available for download to assist you with your build.