How Do I Know I Need New Brakes

Knowing when your brakes need replacing is crucial for both your safety and the longevity of your vehicle. This article will guide you through the key indicators, inspection techniques, and technical considerations involved in determining if it's time for new brakes. We're assuming you're already comfortable with basic car maintenance and have some experience working on your vehicle. This guide is designed to elevate your understanding and empower you to make informed decisions about your brake system.

Purpose: Why Understanding Your Brakes Matters

Understanding your brake system goes beyond simply knowing how to stop. It's about preventative maintenance, cost savings, and ultimately, safety. Early detection of brake issues can prevent more costly repairs down the road, such as replacing rotors or even dealing with caliper damage. Furthermore, understanding the condition of your brakes allows you to maintain optimal stopping performance, which is critical in emergency situations. Whether you're performing routine maintenance, diagnosing a problem, or planning a brake upgrade, knowledge of your brake system is paramount.

Key Specs and Main Parts

The core of your braking system consists of several interconnected components, each with its own lifespan and wear characteristics. Here's a breakdown of the major players:

- Brake Pads: These are the friction material that presses against the rotor to slow the wheel. They are arguably the most frequently replaced component of the brake system.

- Brake Rotors (or Discs): These are the metal discs that the brake pads clamp onto. They wear down over time and can warp or crack.

- Brake Calipers: These house the brake pads and use hydraulic pressure to force the pads against the rotors. They contain pistons that are pushed out by brake fluid.

- Brake Lines: These hoses transport brake fluid from the master cylinder to the calipers. They can become brittle and crack over time, leading to fluid leaks.

- Master Cylinder: This is the reservoir that holds brake fluid and provides the hydraulic pressure needed to actuate the brakes.

- Brake Booster: This uses vacuum from the engine to amplify the force you apply to the brake pedal, making it easier to stop.

- ABS (Anti-lock Braking System) Components: Includes sensors, a control module, and hydraulic valves that prevent wheel lockup during hard braking.

Key Specs to consider when evaluating your brakes include:

- Brake Pad Thickness: Measured in millimeters (mm), this indicates how much friction material remains. A general rule of thumb is that pads should be replaced when they reach 3mm or less. Consult your vehicle's service manual for specific recommendations.

- Rotor Thickness: Also measured in millimeters (mm), this indicates how much material has been worn away from the rotors. Each rotor has a minimum thickness specification; exceeding this limit can lead to rotor failure.

- Brake Fluid Level and Condition: The fluid level should be between the minimum and maximum lines on the master cylinder reservoir. The fluid should be clear and free of contaminants. Dark or murky fluid indicates contamination and the need for a fluid flush.

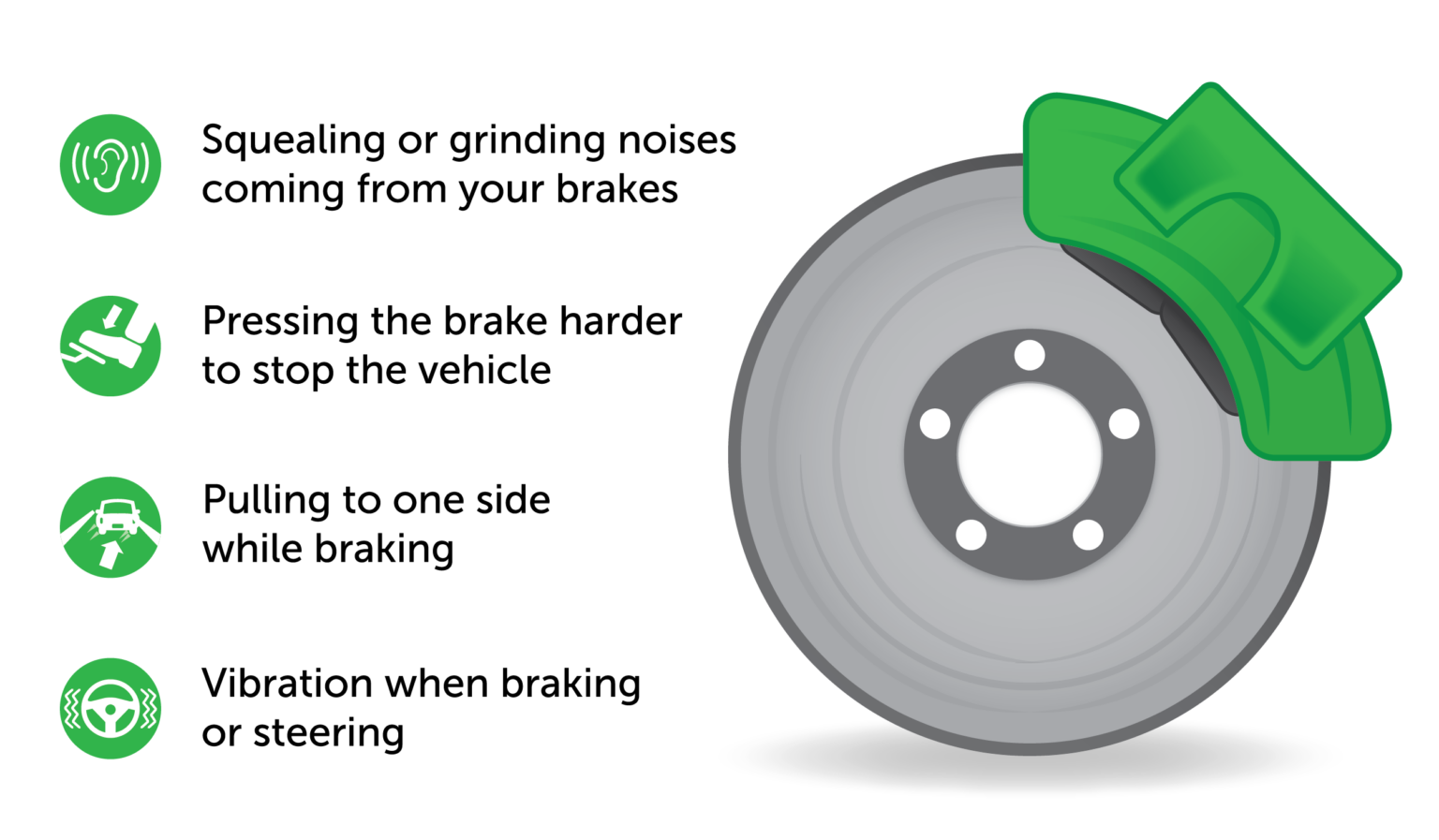

Symbols and Diagnostic Clues

Understanding the warning signs and symptoms of worn brakes can help you diagnose problems early. Here are some common indicators:

- Squealing or Screeching Noises: This is often caused by wear indicators built into the brake pads. These indicators are small metal tabs that rub against the rotor when the pads are worn down to a certain point.

- Grinding Noises: This indicates that the brake pads are completely worn down and the metal backing plates are rubbing against the rotors. This can cause serious damage to the rotors.

- Pulsating Brake Pedal: This can be caused by warped rotors.

- Longer Stopping Distances: This is a general indication that your brakes are not performing optimally.

- Pulling to One Side During Braking: This can be caused by uneven brake pad wear, a sticking caliper, or a problem with the ABS system.

- Brake Warning Light: This light can indicate a variety of problems, including low brake fluid, a problem with the ABS system, or a problem with the brake pressure.

When visually inspecting your brakes, pay attention to the following:

- Cracks or Grooves in the Rotors: Minor surface rust is normal, but deep cracks or grooves indicate the need for rotor replacement.

- Leaking Brake Fluid: Inspect brake lines, calipers, and the master cylinder for signs of leaks. Brake fluid is corrosive and can damage painted surfaces.

- Uneven Brake Pad Wear: This can indicate a problem with the caliper or the brake lines.

How It Works: A Deep Dive into Brake Operation

When you press the brake pedal, you're activating the master cylinder. This cylinder contains pistons that force brake fluid through the brake lines. The fluid travels to the calipers at each wheel. Inside the caliper, the fluid pressure pushes the caliper pistons, which in turn press the brake pads against the rotors. The friction between the pads and rotors slows the wheels down.

The effectiveness of the braking system depends on several factors: the amount of friction between the pads and rotors (affected by pad material and rotor surface), the amount of force applied by the calipers (affected by brake fluid pressure), and the condition of the overall system (including lines, master cylinder, and booster). A poorly maintained system can lead to reduced stopping power and increased stopping distances.

The Anti-lock Braking System (ABS) adds another layer of complexity. During hard braking, ABS sensors monitor the wheel speed. If a wheel starts to lock up, the ABS module modulates the brake pressure to that wheel, preventing it from locking and allowing you to maintain steering control. This modulation happens very quickly, often several times per second. Understanding how ABS works is crucial for diagnosing certain brake problems.

Real-World Use: Basic Troubleshooting Tips

Here are some common brake problems and how to troubleshoot them:

- Squealing Brakes: First, check the brake pad thickness. If the pads are still thick, the squealing may be caused by glazed pads or debris on the rotors. Consider lightly sanding the pads and rotors to remove the glaze. If the squealing persists, try using a brake lubricant on the back of the pads.

- Grinding Brakes: This almost always indicates that the pads are worn down to the metal. Replace the pads immediately and inspect the rotors for damage. If the rotors are deeply scored, they may need to be replaced as well.

- Pulsating Brakes: This is usually caused by warped rotors. The best solution is to replace the rotors. In some cases, you may be able to have the rotors resurfaced, but this will reduce their thickness and may not be a long-term solution.

- Spongy Brake Pedal: This can be caused by air in the brake lines. Bleed the brake lines to remove the air. Also, check for leaks in the brake lines and master cylinder.

- Brake Fade: This occurs when the brakes overheat and lose their effectiveness. This can happen during prolonged periods of heavy braking, such as driving down a steep mountain. Allow the brakes to cool down before continuing to drive. Consider upgrading to performance brake pads and rotors if you frequently experience brake fade.

Safety: Highlighting Risky Components

The brake system is a critical safety component of your vehicle. Working on the brake system requires careful attention to detail and adherence to safety precautions. Always use jack stands to support the vehicle when working underneath it. Never rely on just the jack.

Brake fluid is corrosive and can damage painted surfaces. Wear eye protection and gloves when working with brake fluid. If brake fluid gets on your skin, wash it off immediately with soap and water.

The ABS system contains high-pressure components. If you're working on the ABS system, disconnect the battery to prevent accidental activation. Some ABS systems require special tools and procedures for bleeding. Consult your vehicle's service manual for specific instructions.

Incorrectly installed brake components can lead to brake failure. If you're not comfortable working on the brake system, take your vehicle to a qualified mechanic. It's always better to be safe than sorry when it comes to your brakes.

Finally, always bed in new brake pads and rotors according to the manufacturer's instructions. This involves a series of controlled stops that help to transfer the friction material from the pads to the rotors, ensuring optimal braking performance.

We have a detailed diagram of a typical disc brake system available for download. This diagram provides a visual representation of the components and their relationships, further enhancing your understanding. Contact us to retrieve it.