How Do I Turn On 4 Wheel Drive

So, you want to delve into the world of 4-wheel drive (4WD) and understand how to engage it correctly and safely? Excellent! Whether you're looking to understand your vehicle's system better for maintenance, planning an upgrade, or just want to know what's happening under the hood (or chassis, in this case), grasping the principles behind 4WD activation is essential. This article will guide you through the process, covering everything from the key components and how they interact to troubleshooting common issues.

Purpose of Understanding 4WD Engagement

Why bother understanding the nitty-gritty details of how your 4WD system engages? Well, there are several compelling reasons. For one, proper engagement and disengagement are crucial for preventing damage to your drivetrain. Using 4WD inappropriately on high-traction surfaces like paved roads can lead to significant stress and premature wear on components like the transfer case, axles, and differentials. Secondly, a deeper understanding allows for more informed troubleshooting. When things go wrong – and they inevitably will at some point – knowing the symptoms and potential causes can save you time, money, and frustration. Finally, if you're considering modifications or upgrades to your 4WD system, a solid understanding of the existing setup is indispensable. Whether you're thinking about adding a lift kit, swapping axles, or installing a new transfer case, you'll need to know how the system works together to ensure compatibility and proper function.

Key Specs and Main Parts

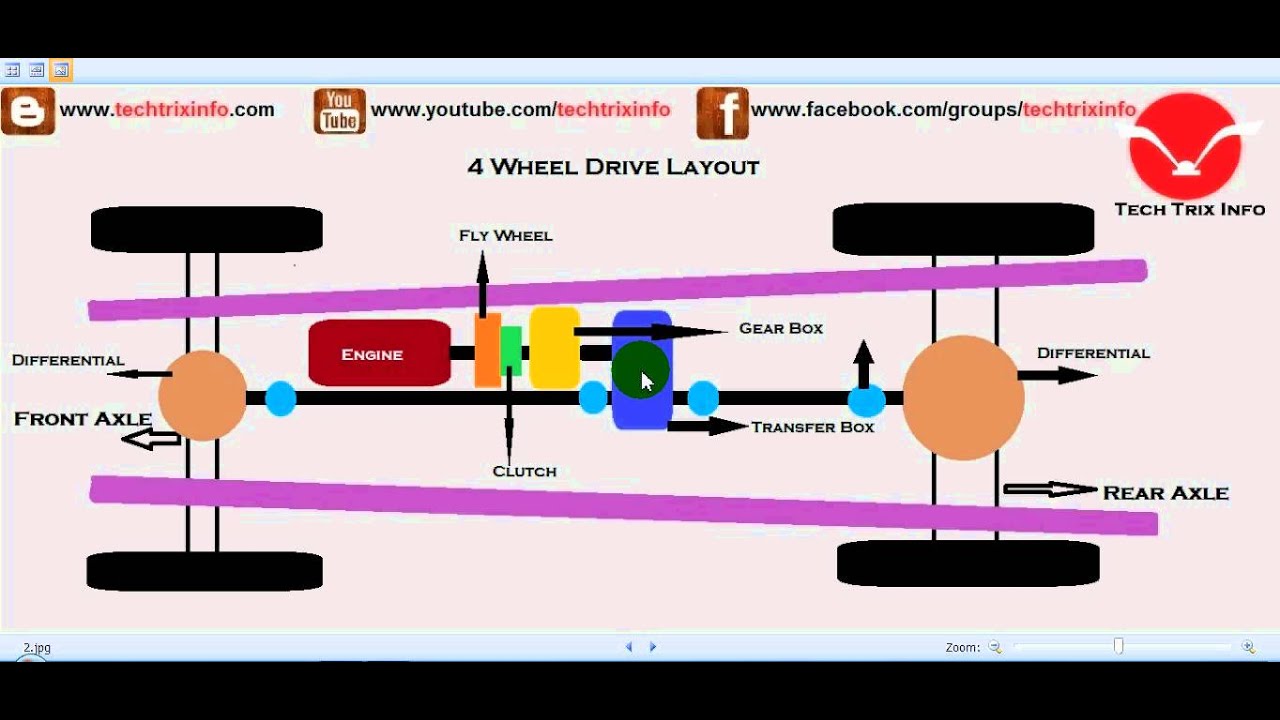

Let's break down the core components involved in engaging 4WD. While the specifics can vary depending on the make, model, and year of your vehicle, the fundamental principles remain largely the same. Here’s a rundown of the main players:

- Transfer Case: The heart of the 4WD system. This unit takes power from the transmission and distributes it to both the front and rear axles. It usually offers multiple modes, including 2-wheel drive (2WD), 4-wheel drive high (4H), and 4-wheel drive low (4L). The transfer case can be either part-time or full-time. Part-time systems require manual engagement, while full-time systems can automatically distribute power as needed.

- Front Axle: This axle transmits power to the front wheels. It typically includes a differential to allow the wheels to rotate at different speeds during turns. Some front axles also incorporate a disconnect mechanism to improve fuel economy in 2WD mode. This disconnect can be vacuum-operated, electrically actuated, or mechanically linked.

- Rear Axle: Similar to the front axle, the rear axle transmits power to the rear wheels. It also includes a differential. In many 4WD vehicles, the rear axle is always "live," meaning it's always receiving power when the vehicle is in motion.

- Shift Mechanism: This is the interface you use to select the desired 4WD mode. It can be a lever on the floor, buttons on the dashboard, or an electronic dial. The shift mechanism controls the internal components of the transfer case, engaging or disengaging the front axle and selecting the appropriate gear ratio.

- Actuators: These are the components that physically shift the transfer case or disconnect the front axle. They can be vacuum-powered, electric motors, or even cable-operated linkages. A common issue is a failing actuator motor.

How It Works: The Engagement Process

The engagement process varies depending on the type of 4WD system in your vehicle. Let’s examine a typical part-time 4WD system with a manual shift lever:

- Selecting 4H: When you move the shift lever to the 4H position, you're mechanically linking the front and rear driveshafts within the transfer case. This typically involves a shift fork moving a synchronizer or collar to engage the front driveshaft output shaft.

- Front Axle Engagement: Depending on the vehicle, the front axle may engage automatically or require a separate action. Some systems utilize an automatic hub engagement mechanism (vacuum or electric) which engages when the transfer case shifts into 4H. Older systems may require manually locking the front hubs.

- Power Distribution: Once both axles are engaged, the engine's power is split between the front and rear wheels. The transfer case has a fixed gear ratio in 4H, typically a 1:1 ratio (no gear reduction).

- Selecting 4L: Shifting into 4L involves engaging a lower gear ratio within the transfer case, typically in the range of 2:1 to 3:1. This provides increased torque at the wheels, ideal for crawling over obstacles or navigating steep terrain. Selecting 4L usually requires the vehicle to be stopped and in neutral.

In an electronic shift system, the process is similar, but the shift lever or buttons activate electric motors that perform the same actions as the manual linkages.

Real-World Use: Basic Troubleshooting Tips

Here are some common issues you might encounter with your 4WD system and how to troubleshoot them:

- 4WD Won't Engage: Check the shift mechanism for proper function. Listen for the actuator motor working. Ensure the front hubs are locked (if applicable). If there is no noise from the motor and the lights do not activate, check the electrical system. Look for blown fuses or loose connections. A scan tool can often pinpoint electronic issues.

- Grinding Noise When Engaging 4WD: This could indicate worn synchronizers in the transfer case or a problem with the front axle engagement mechanism. Try engaging 4WD while moving slowly, as some systems require a slight amount of wheel rotation to engage properly. Immediately stop and have the system checked by a professional.

- 4WD Disengages Unexpectedly: This could be due to a faulty actuator, a vacuum leak in the hub engagement system, or a problem with the shift linkage. Again, start with checking fuses and vacuum lines.

- Stiff Shifting: This is common in older vehicles. Regular lubrication of the shift linkages can help. Also, ensure the vehicle is completely stopped and in neutral when shifting between 2H and 4L.

Safety: Risks and Precautions

Working on a 4WD system can be dangerous if proper precautions are not taken. Here are some key safety considerations:

- Disconnect the Battery: Always disconnect the negative battery terminal before working on any electrical components of the 4WD system.

- Support the Vehicle Properly: When working under the vehicle, use jack stands to support it securely. Never rely solely on a jack.

- Wear Safety Glasses: Protect your eyes from debris.

- Release Pressure: When working on hydraulic or vacuum systems, be sure to release any stored pressure before disconnecting lines or fittings.

- Be Aware of Rotating Parts: When the engine is running, be extremely careful around rotating parts such as the driveshafts.

- Consult a Professional: If you are unsure about any aspect of the repair, consult a qualified mechanic. Drivetrain components are critical for vehicle safety.

- High Traction Surfaces: As mentioned before, do not use 4H or 4L on high-traction surfaces like dry pavement. This can cause drivetrain binding and damage.

Diagrams and Further Resources

To truly understand your specific 4WD system, a detailed wiring diagram is invaluable. We have a library of diagrams available, and you can request access to the diagram for your specific vehicle. Send us your make, model, and year, and we'll provide the relevant schematic. These diagrams typically show all the electrical connections, actuators, sensors, and control modules involved in the 4WD system. They are essential for troubleshooting electrical issues and understanding how the system communicates.

Understanding your 4WD system empowers you to maintain it effectively, diagnose problems accurately, and make informed decisions about modifications and upgrades. Happy off-roading!