How Do Turbos Work On A Car

So, you want to understand how turbos work? Excellent! This article will give you a solid grasp of turbocharger operation, from the key components to basic troubleshooting. Understanding this technology is crucial if you're considering performance upgrades, troubleshooting engine issues, or simply want to know what's going on under the hood of your turbocharged vehicle. Knowing the ins and outs of your turbocharger empowers you to diagnose potential problems, discuss repairs intelligently with your mechanic, and maybe even tackle some DIY projects. We'll even highlight some safety considerations to keep you out of trouble when working around these powerful devices.

Key Specs and Main Parts

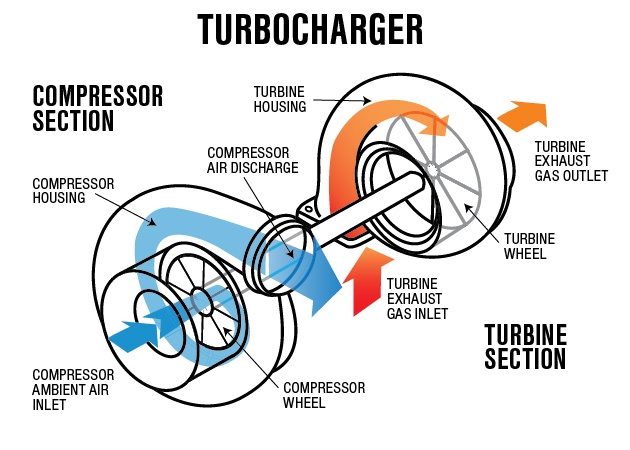

At its heart, a turbocharger is an air pump, driven not by the engine itself, but by the engine's exhaust gases. Its purpose is to force more air into the engine cylinders than they could draw in on their own, a process known as forced induction. This increased air density allows the engine to burn more fuel, resulting in a significant increase in power.

The main components of a turbocharger are:

- Turbine Wheel and Housing: This assembly is located in the exhaust stream. The turbine wheel is a precisely engineered bladed rotor that spins when exhaust gases flow across it. The turbine housing is designed to channel the exhaust flow efficiently onto the turbine wheel. Key specs here include the A/R ratio (Area/Radius), which influences the turbo's spool-up time and top-end power. A smaller A/R typically provides quicker spool-up but may limit top-end flow, while a larger A/R favors top-end power at the expense of quicker spool.

- Compressor Wheel and Housing: Connected to the turbine wheel by a shared shaft, the compressor wheel is also a bladed rotor, but its purpose is to compress intake air. As the turbine wheel spins, it drives the compressor wheel, drawing in air and forcing it into the engine's intake manifold at a higher pressure. The compressor housing is designed to optimize airflow to the compressor wheel. Again, A/R ratios play a crucial role.

- Shaft: A robust, precisely balanced shaft connects the turbine and compressor wheels. This shaft rotates at incredibly high speeds, often exceeding 100,000 RPM.

- Bearing System: The shaft spins within a bearing system, which can be either a traditional journal bearing system or a ball bearing system. Ball bearing systems generally offer reduced friction and faster spool-up times.

- Wastegate: The wastegate is a valve that regulates the amount of exhaust gas flowing to the turbine wheel. Its purpose is to prevent the turbocharger from over-boosting (producing excessive intake pressure). A wastegate can be internal (integrated into the turbine housing) or external (a separate unit).

- Blow-Off Valve (BOV) or Diverter Valve: Located in the intake tract, this valve vents excess pressure when the throttle is closed. This prevents compressor surge (a damaging backflow of air through the compressor wheel) and improves throttle response. A BOV vents to the atmosphere, creating a characteristic whooshing sound, while a diverter valve recirculates the air back into the intake system.

- Intercooler: The process of compressing air generates heat. An intercooler is a heat exchanger that cools the compressed air before it enters the engine. Cooler air is denser, allowing for even more efficient combustion and increased power.

How It Works

Let's break down the process step-by-step:

- Exhaust Gases Drive the Turbine: Exhaust gases exiting the engine are directed into the turbine housing. The force of these gases impinging on the turbine wheel causes it to spin rapidly.

- The Turbine Spins the Compressor: Because the turbine and compressor wheels are connected by a shared shaft, the rotation of the turbine wheel directly drives the compressor wheel.

- The Compressor Compresses Intake Air: As the compressor wheel spins, it draws in ambient air through the air filter and compresses it.

- Compressed Air is Cooled (Often): The compressed, heated air is then routed through the intercooler, where it is cooled down.

- Air Enters the Engine: The cooled, compressed air enters the engine's intake manifold, ready to be mixed with fuel and combusted.

- Wastegate Regulation: As the turbocharger spins faster and boost pressure increases, the wastegate will open, bypassing exhaust gasses around the turbine wheel to maintain a pre-set boost level.

- Blow-off Valve Function: When the throttle is suddenly closed the blow-off valve releases built up pressure in the intake system to prevent compressor surge.

Real-World Use – Basic Troubleshooting Tips

Here are some common symptoms of turbocharger problems and potential causes:

- Loss of Power: Could indicate a boost leak (a hole or crack in the intake plumbing), a faulty wastegate, a failing turbocharger, or a clogged air filter. Check all hoses and connections for leaks. A boost gauge can help you monitor boost pressure.

- Excessive Smoke: Blue smoke suggests oil burning, potentially due to worn turbocharger seals. Black smoke indicates excessive fuel, possibly caused by a malfunctioning fuel system trying to compensate for a perceived lack of boost.

- Whining or Screeching Noise: Could indicate damaged turbine or compressor blades, worn bearings, or a loose exhaust manifold gasket.

- Check Engine Light: Many turbocharger-related issues will trigger a check engine light. Scan the computer for diagnostic trouble codes (DTCs) to help pinpoint the problem.

Important: Before attempting any repairs, consult your vehicle's service manual. Incorrect repairs can cause serious engine damage.

Safety – Highlight Risky Components

Working on or around a turbocharger involves some inherent risks:

- Hot Surfaces: The turbine housing and exhaust manifold can reach extremely high temperatures. Always allow the engine to cool completely before working on the turbocharger. Use heat-resistant gloves.

- Rotating Parts: The turbine and compressor wheels spin at incredible speeds. Never attempt to disassemble or inspect the turbocharger while the engine is running.

- Boost Pressure: High boost pressures can cause serious injury if not handled carefully. Always depressurize the system before disconnecting any hoses or components.

- Oil Lines: Turbochargers require a constant supply of oil for lubrication. Leaking oil lines can create a fire hazard. Ensure all oil lines are properly connected and free of leaks.

Always wear safety glasses and gloves when working on any automotive system.

Conclusion

Understanding how a turbocharger works is a valuable skill for any car enthusiast or DIY mechanic. By grasping the principles of forced induction and the function of each component, you'll be better equipped to diagnose problems, make informed decisions about upgrades, and keep your turbocharged vehicle running smoothly. Remember to prioritize safety and consult your vehicle's service manual before attempting any repairs. Armed with this knowledge, you're well on your way to becoming a turbo expert!

We have a detailed diagram of a turbocharger system available for download. This diagram includes labeled components, flow paths, and other helpful information. Contact us to gain access to the file.