How Do You Blow A Transmission

Alright, let's talk about transmissions. Specifically, let's talk about how to not turn yours into a pile of expensive scrap metal. We're going to delve into the ways transmissions fail, essentially covering how to "blow" one up. This isn't a how-to guide for destruction, mind you. Understanding failure modes is crucial for preventative maintenance, performance modifications, and even diagnosing issues when things go wrong. Whether you're planning on upgrading your engine, towing heavy loads, or just want to keep your daily driver running smoothly, knowing the weak points of your transmission can save you a ton of money and headaches.

Purpose of Understanding Transmission Failure

Why should you care about the inner workings of a dying transmission? Well, several reasons come to mind. First, diagnosing transmission problems early can prevent a minor issue from snowballing into a catastrophic failure. Second, if you're planning on increasing your engine's power, understanding the transmission's limits is paramount. A stock transmission may not handle the extra torque, leading to a premature demise. Third, if you are attempting a repair, you need to know what you are doing to avoid further damaging the transmission. Finally, knowledge is power, and understanding the complexities of the transmission allows for smarter decision-making when it comes to maintenance and upgrades.

Key Specs and Main Parts

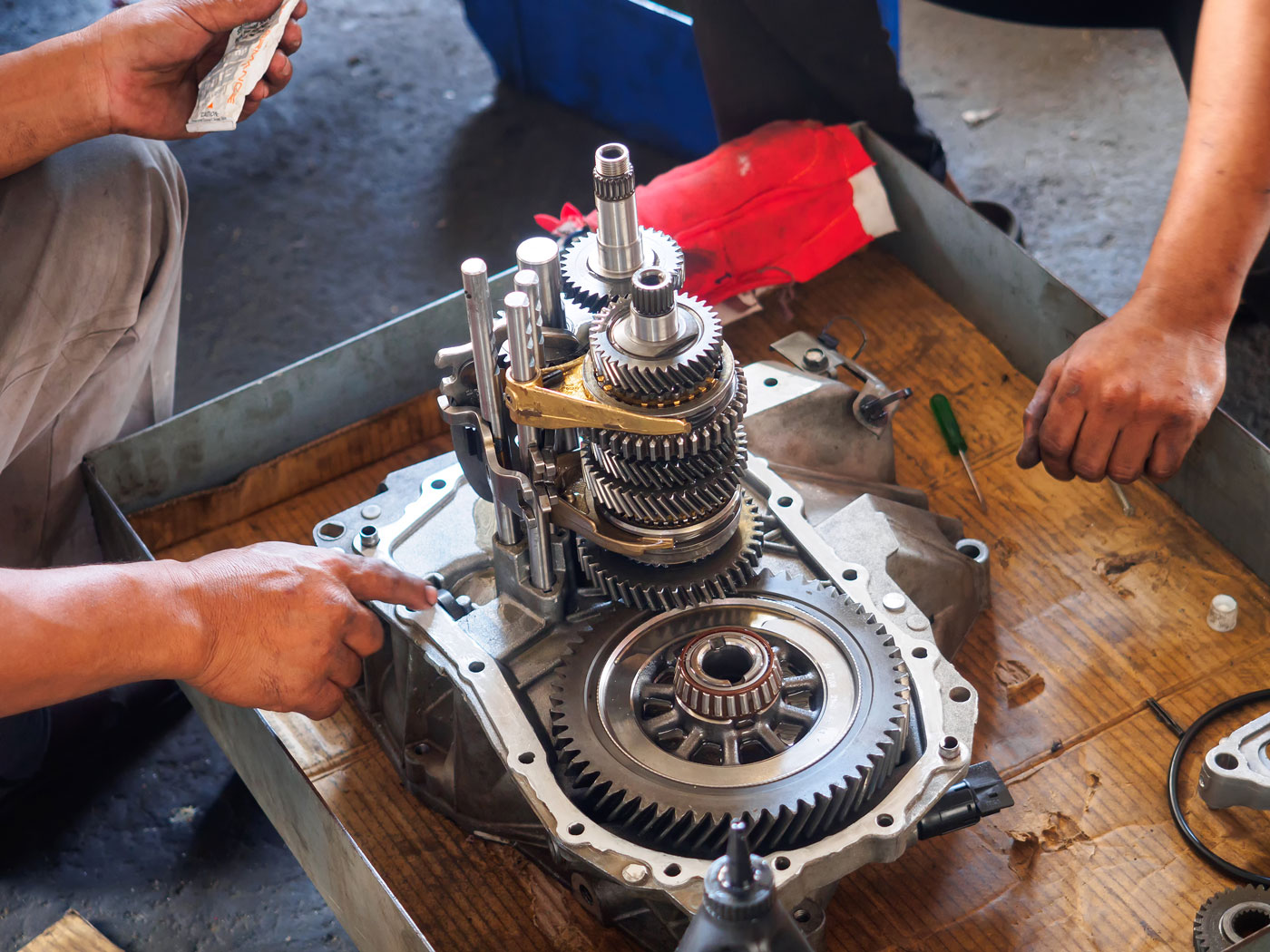

Transmissions, whether manual or automatic, share some fundamental components. Here's a breakdown:

- Input Shaft: This is where the engine's power enters the transmission. It's connected directly to the clutch (in a manual) or the torque converter (in an automatic).

- Gears: These are the heart of the transmission. Different sized gears provide different gear ratios, allowing the engine to operate efficiently at various speeds.

- Shafts (Main, Counter, Output): These shafts support the gears and transmit power through the transmission. The main shaft typically aligns with the input shaft. The counter shaft provides an intermediate point for gear meshing. The output shaft delivers power to the driveshaft and, ultimately, the wheels.

- Synchronizers (Manual Transmissions): These components match the speeds of the gears before they engage, preventing grinding. A worn or damaged synchronizer will result in difficulty shifting and that dreaded "grinding" noise.

- Clutch (Manual Transmissions): The clutch connects and disconnects the engine from the transmission, allowing for gear changes.

- Torque Converter (Automatic Transmissions): This fluid coupling multiplies torque at low speeds and allows the engine to idle without stalling when the vehicle is stopped.

- Valve Body (Automatic Transmissions): The "brain" of an automatic transmission. It uses hydraulic pressure to control the shifting of gears based on engine load, vehicle speed, and other factors.

- Clutches and Bands (Automatic Transmissions): These components engage and disengage different gear sets within the transmission. Slipping clutches or bands are a common cause of automatic transmission failure.

- Planetary Gear Sets (Automatic Transmissions): Allows for various gear ratios to be achieved within a compact space.

- Transmission Fluid: Acts as a lubricant, coolant, and hydraulic fluid. Maintaining the correct fluid level and condition is crucial for transmission health.

- Seals and Gaskets: Prevent fluid leaks. Leaks can lead to low fluid levels and overheating, ultimately damaging the transmission.

Key specs to keep in mind include the transmission's torque capacity (how much torque it can handle before failing) and the gear ratios (which determine the vehicle's acceleration and fuel efficiency). Understanding these specs is critical when choosing a transmission for a particular application, especially if you're modifying your vehicle for increased power.

How It Works (Simplified)

Let's break down the basics of how a transmission operates.

Manual Transmission: When you press the clutch pedal, you disconnect the engine from the transmission. You then select a gear, which engages a specific set of gears on the input and output shafts. Releasing the clutch smoothly re-establishes the connection between the engine and the transmission, transmitting power to the wheels through the selected gear ratio.

Automatic Transmission: The torque converter transmits power from the engine to the transmission. The valve body, using hydraulic pressure, controls the engagement of clutches and bands, which in turn select different gear ratios within the planetary gear sets. This process happens automatically, without the driver needing to manually shift gears.

How You Blow It Up (and How to Prevent It)

Here's the juicy part. While there are many failure modes, some are more common than others:

- Overheating: Excessive heat is a transmission's worst enemy. It breaks down the transmission fluid, reducing its lubricating properties and causing increased wear and tear on the internal components. Towing heavy loads, aggressive driving, and low fluid levels can all contribute to overheating. Prevention: Install a transmission cooler, regularly check and change the fluid, and avoid overloading your vehicle.

- Low Fluid Level: Leaks in seals or gaskets can lead to low fluid levels. Without enough fluid, the transmission won't be properly lubricated or cooled, leading to rapid wear and eventual failure. Prevention: Regularly check for leaks and address them promptly. Ensure the fluid level is within the recommended range.

- Contaminated Fluid: Dirt, metal shavings, and other contaminants can get into the transmission fluid, acting as abrasives and accelerating wear. Prevention: Follow the manufacturer's recommended fluid change intervals. Consider installing a transmission filter to remove contaminants.

- Abusive Shifting (Manual Transmissions): "Speed shifting" or forcing gears can damage synchronizers and other internal components. Prevention: Practice smooth, controlled shifting. Use the clutch properly.

- Torque Converter Failure (Automatic Transmissions): The torque converter can fail due to overheating, contamination, or wear. Symptoms include slipping, stalling, and unusual noises. Prevention: Maintain the transmission fluid and avoid excessive towing or aggressive driving.

- Valve Body Issues (Automatic Transmissions): A malfunctioning valve body can cause erratic shifting, slipping, or complete loss of drive. Prevention: Regular fluid changes and avoiding overheating can help prevent valve body problems.

- Exceeding Torque Capacity: Putting more power through the transmission than it was designed to handle will inevitably lead to failure. This is common with engine modifications. Prevention: Upgrade the transmission to a stronger unit if you're increasing engine power.

Real-World Use – Basic Troubleshooting Tips

Okay, so you suspect your transmission is on its way out. Here are some basic troubleshooting steps:

- Check the Fluid: Is it low? Does it smell burnt? Is it dark and sludgy? These are all signs of potential problems.

- Listen for Noises: Grinding, whining, or clunking noises can indicate specific issues.

- Pay Attention to Shifting: Is it hard to shift? Is it slipping out of gear? Are the shifts erratic or delayed?

- Look for Leaks: Check around the transmission housing for fluid leaks.

If you notice any of these symptoms, it's best to consult with a qualified mechanic or transmission specialist. Ignoring these problems will only lead to more extensive and expensive repairs down the road.

Safety – Highlight Risky Components

Working on a transmission can be dangerous. Here are some safety precautions to keep in mind:

- Hot Fluid: Transmission fluid can get extremely hot. Allow the transmission to cool down before working on it.

- Heavy Components: Transmissions are heavy and awkward to handle. Use proper lifting equipment and techniques to avoid injury.

- Pressurized Systems: Automatic transmissions operate with pressurized hydraulic systems. Relieve pressure before disconnecting any lines or components.

- Eye Protection: Wear safety glasses to protect your eyes from flying debris.

- Proper Tools: Use the correct tools for the job. Using the wrong tool can damage the transmission or cause injury.

Specifically, be extremely careful when dealing with the torque converter. It can be heavy and contains fluid under pressure. Also, avoid getting transmission fluid on your skin, as it can be irritating.

Access to Diagrams

To help you visualize the components and how they interact, we have detailed transmission diagrams available. These diagrams break down the transmission into its individual parts, allowing you to see how everything fits together. Feel free to download the diagrams [link to diagram file here]. These diagrams can be invaluable for understanding transmission operation, diagnosing problems, and planning repairs.