How Do You Check Your Alternator

So, you suspect your alternator might be on its way out? Don't worry, you've come to the right place. Diagnosing alternator issues is a skill every DIY mechanic should have. This isn't just about saving money on shop bills; it's about understanding your car's electrical system and being able to keep it running smoothly. We're going to walk through the process step-by-step, covering everything from basic testing to interpreting circuit diagrams. And yes, we'll get to the nitty-gritty technical details, but I'll explain them in a way that's easy to understand, even if you're not an electrical engineer.

Purpose: Why Bother Checking Your Alternator?

Let's be clear: a faulty alternator can leave you stranded. The alternator is the heart of your car's electrical charging system. Its primary job is to replenish the battery's charge after starting the engine and to provide power to all the electrical components while the engine is running. Think of it this way: the battery gets the engine going, but the alternator keeps everything else alive. Here's why knowing how to check it is crucial:

- Preventative Maintenance: Catching a failing alternator early can prevent a breakdown and potentially damage to other components, like your battery.

- Accurate Diagnosis: Many electrical problems *seem* like they're battery related, but are actually caused by a faulty alternator. Knowing how to test it helps you pinpoint the *real* issue.

- Cost Savings: Replacing an alternator yourself is often cheaper than taking it to a shop. Plus, you'll learn valuable skills in the process.

- Performance Enhancement: If you're upgrading your car's electrical system (adding a high-power stereo, for example), knowing your alternator's output capacity and health is essential.

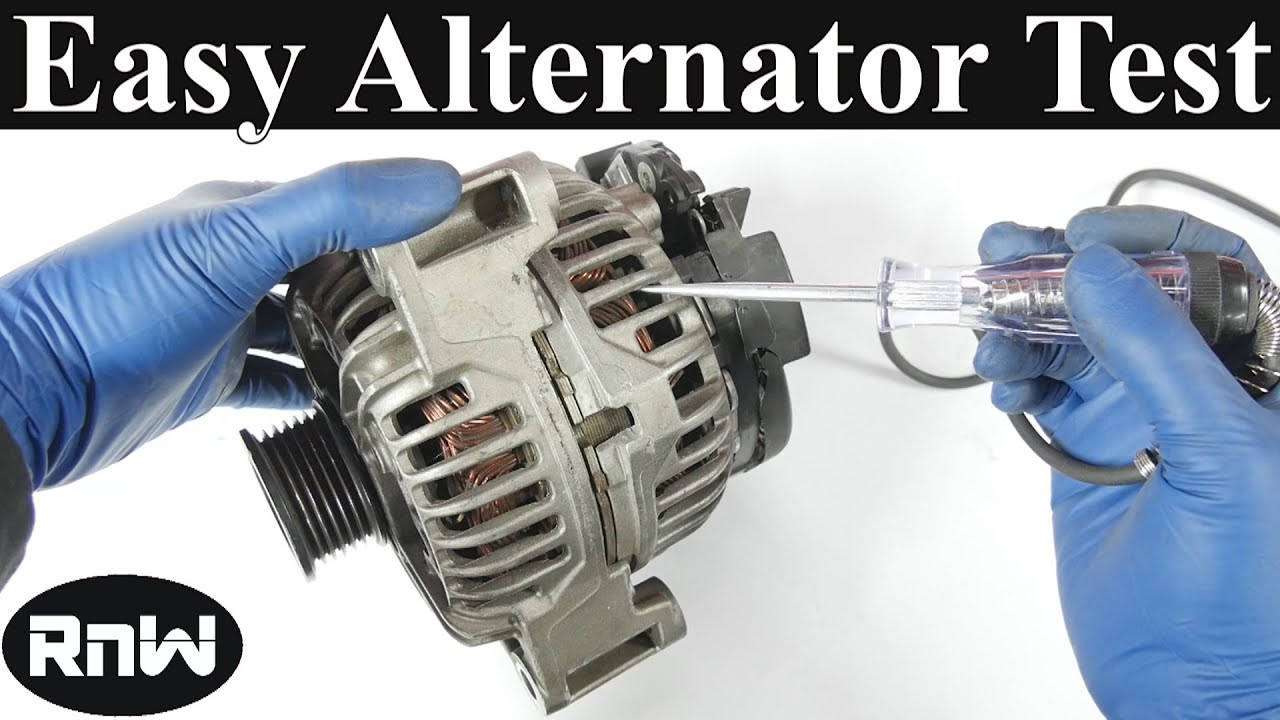

Key Specs and Main Parts

Before we dive into testing, let's familiarize ourselves with the key specifications and parts of an alternator.

Key Specs:

- Voltage Output: Typically, alternators are designed to output between 13.5 and 14.5 volts while the engine is running. This voltage is *crucial* for charging the battery and powering the electrical system. Deviations from this range indicate a problem.

- Amperage Output: This refers to the alternator's current (amp) generating capacity. It indicates how much electrical load the alternator can handle at once. A higher amperage alternator is needed for vehicles with many electrical accessories. This varies greatly from vehicle to vehicle.

- Duty Cycle: This refers to how long the alternator can operate at its maximum rated output before overheating. This spec is usually not directly available to the consumer, but it is related to the overall cooling design.

Main Parts:

- Stator: The stationary part of the alternator that contains the windings where electricity is generated. It's essentially a coil of wire.

- Rotor: The rotating part of the alternator, which is connected to the engine via a belt. It contains a magnetic field that interacts with the stator windings.

- Rectifier/Diode Bridge: Alternators generate AC (Alternating Current) electricity, but car electrical systems use DC (Direct Current). The rectifier converts the AC to DC. Diodes are one-way valves for electricity, preventing current from flowing backwards.

- Voltage Regulator: This crucial component maintains a constant voltage output from the alternator, preventing overcharging or undercharging the battery. It regulates the current flowing to the rotor.

- Brushes: Conductive components that make contact with the slip rings on the rotor to supply excitation current. They eventually wear down.

- Slip Rings: Smooth metal bands on the rotor that the brushes ride on.

- Housing: The metal casing that protects the internal components of the alternator.

How It Works: A Simplified Explanation

The alternator's operation relies on the principle of electromagnetic induction. Here's a simplified breakdown:

- The engine turns the rotor of the alternator via a belt.

- The voltage regulator controls the amount of current supplied to the rotor, creating a magnetic field.

- As the rotor spins, its magnetic field interacts with the stator windings, inducing an alternating current (AC).

- The rectifier (diode bridge) converts the AC current into direct current (DC).

- The voltage regulator ensures that the output voltage remains within the specified range (e.g., 13.5-14.5 volts).

- The DC voltage is then used to charge the battery and power the car's electrical system.

Real-World Use: Basic Troubleshooting Tips

Here are some common symptoms of a failing alternator and basic troubleshooting steps you can take:

- Dim or Flickering Headlights: This is a classic sign of an undercharging alternator.

- Battery Warning Light: This light indicates a problem with the charging system, which often points to the alternator.

- Difficulty Starting the Engine: While this could be a battery issue, a failing alternator that isn't properly charging the battery can also cause starting problems.

- Stalling Engine: In some cases, a failing alternator can cause the engine to stall, especially at idle.

- Whining or Growling Noises: A worn-out bearing in the alternator can produce noticeable noises.

- Using a Multimeter: The most reliable way to test an alternator is with a multimeter. With the engine running, check the voltage at the battery terminals. It should be between 13.5 and 14.5 volts. If it's significantly lower or higher, the alternator or voltage regulator is likely faulty.

- Load Test: A load test simulates a high electrical demand on the alternator. This test is often performed at an auto parts store.

Safety: Risky Components

Working with electrical systems can be dangerous if you're not careful. Here are some key safety precautions to keep in mind:

- Disconnect the Battery: *Always* disconnect the negative battery terminal before working on any part of the electrical system. This prevents accidental short circuits.

- Avoid Touching Terminals: Be extremely careful when working around the alternator terminals. Accidental contact with the positive terminal can cause severe shocks or burns.

- Wear Safety Glasses: Protect your eyes from sparks or debris.

- Use Insulated Tools: Using tools with insulated handles reduces the risk of electric shock.

- Don't Work in Wet Conditions: Water conducts electricity. Avoid working on the electrical system in wet or damp environments.

- Working on a running engine: Keep your hair, clothing, and tools away from moving parts like the belt. A snapped belt can cause injury.

The most significant risk is a short circuit that can result in fire or serious injury. Exercise extreme caution and consult a qualified mechanic if you're unsure about any step of the process.

Interpreting Circuit Diagrams (Lines, Colors, and Icons)

Understanding alternator circuit diagrams is essential for advanced troubleshooting and modifications. Here's a breakdown of common symbols and conventions:

Lines:

- Solid Lines: Represent wires or conductors carrying electrical current. The thickness of the line sometimes indicates the wire gauge (thicker lines for higher current).

- Dashed Lines: Often represent shielding or grounding paths.

- Arrows: Indicate the direction of current flow (typically from positive to negative).

Colors:

Wire colors are standardized to a certain extent, but can vary depending on the manufacturer. Common colors include:

- Red: Positive voltage (+) – often the main power wire.

- Black: Ground (-) – the return path for the current.

- Yellow: Typically used for ignition or accessory circuits.

- Blue: Often used for lighting circuits.

- Green: Can be used for various functions, including signaling.

Note: *Always* refer to the specific wiring diagram for your vehicle, as color coding can vary.

Icons:

- Alternator Symbol: Usually a circle with the letters "ALT" or a stylized representation of a generator.

- Battery Symbol: Typically a series of vertical lines representing the battery plates, with "+" and "-" symbols indicating the terminals.

- Fuse Symbol: A zigzag line enclosed in a rectangle, indicating a fuse for circuit protection.

- Relay Symbol: A coil symbol (representing the relay's electromagnet) and a switch symbol (representing the relay's contacts).

- Ground Symbol: Various symbols are used to represent ground connections, often resembling a rake or a downward-pointing triangle.

- Voltage Regulator Symbol: Usually a rectangle with terminals, may be labeled "VR".

By studying the circuit diagram, you can trace the flow of electricity, identify potential problem areas, and make informed decisions about repairs or modifications.

We have a detailed alternator circuit diagram file available for you to download. This diagram shows a typical automotive alternator circuit, including the battery, voltage regulator, and associated wiring. It's a valuable resource for understanding how the alternator interacts with the rest of your car's electrical system. With this knowledge and the right tools, you'll be well-equipped to diagnose and address alternator problems effectively.