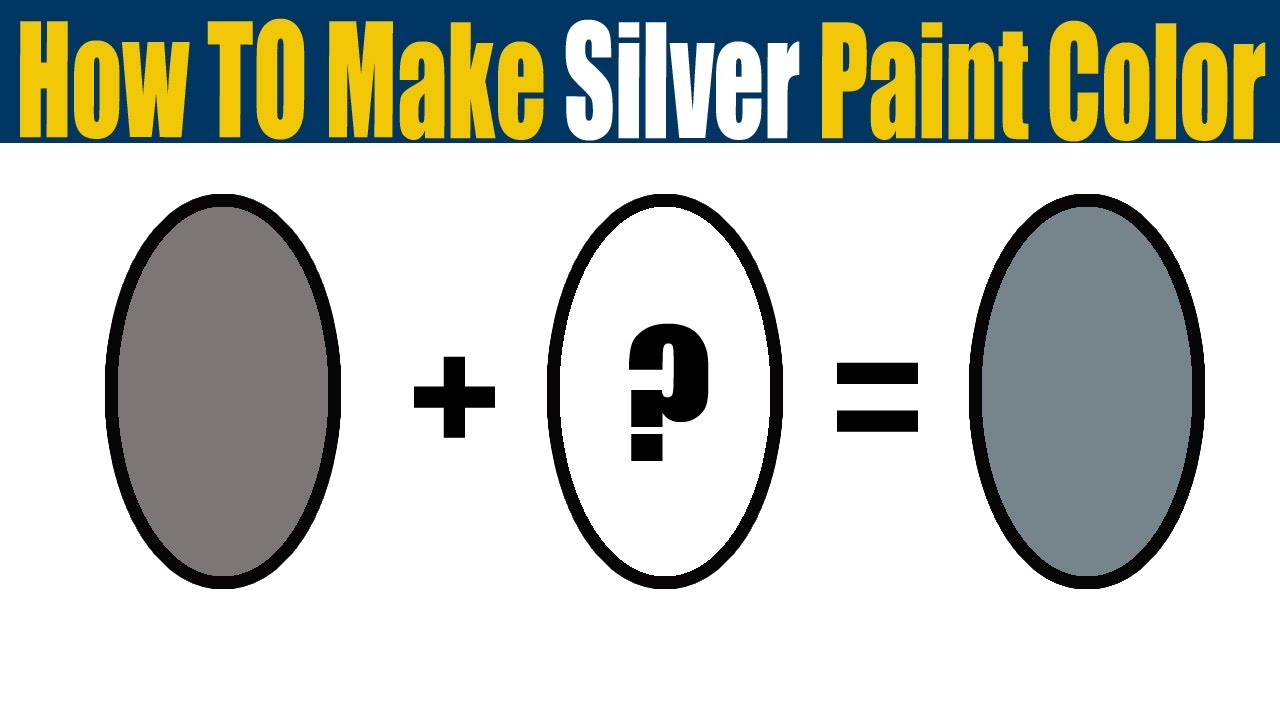

How Do You Make The Color Silver

So, you're looking to create the elusive color of silver. It's a popular choice in the automotive world, lending a sleek, modern look to everything from body panels to trim pieces. But achieving a true, convincing silver isn't as simple as just slapping on some gray paint. It requires understanding pigments, reflectivity, and how light interacts with the applied finish. This article breaks down the process, similar to understanding a complex wiring diagram before tackling an electrical project on your ride.

Purpose: More Than Just Aesthetics

Understanding how silver paint is made isn't just for cosmetic reasons. Knowing the ingredients and process can be crucial for:

- Repairing Scratches and Chips: Matching the exact shade and finish of your car's existing silver paint is vital for seamless repairs.

- Customization and Modifications: If you're modifying your car, knowing the fundamentals allows you to experiment with different silver tones and effects.

- Troubleshooting Paint Issues: Understanding the composition can help you identify the cause of paint defects like fading, discoloration, or orange peel.

- Cost Savings: Learning to mix your own silver can be more cost effective than continuously buying pre-mixed paints, especially for larger projects.

Key Specs and Main Parts: The Silver Paint Recipe

Creating silver paint involves a specific combination of components. Consider this our schematic diagram for mixing your ideal silver shade.

Pigments: The Foundation of Color

The pigments are the insoluble particles that give the paint its color. For silver, we rely on:

- Aluminum Flakes (Metallic Pigment): These are the heart of silver paint. The size, shape, and alignment of these flakes determine the metallic effect and brilliance. Larger flakes create a more sparkly, "coarse" metallic look, while smaller flakes result in a smoother, finer shimmer.

- Gray Pigments (Non-Metallic): These are usually carbon black or titanium dioxide (white) mixed to achieve the desired shade of gray. The specific ratio influences the depth and tone of the silver.

- Color Tint (Optional): Sometimes, a very small amount of color tint (e.g., blue, green, or gold) is added to create unique variations of silver, like "Ice Blue Silver" or "Champagne Silver."

Binder (Resin): Holding It All Together

The binder is the liquid component that suspends the pigments and provides adhesion to the surface. Common binders include:

- Acrylic Lacquer: Dries quickly but is less durable and environmentally friendly.

- Acrylic Enamel: More durable than lacquer and provides a good gloss.

- Urethane: Offers excellent durability, chemical resistance, and gloss retention, making it ideal for automotive applications.

- Water-Based Acrylic: Environmentally friendly and easy to clean up but may require more coats for optimal coverage.

Solvent (Reducer): Adjusting Viscosity

The solvent thins the paint to the desired viscosity for spraying or brushing. The appropriate solvent depends on the type of binder used. Always use the manufacturer's recommended solvent.

Additives: Fine-Tuning Performance

Additives are used to improve specific properties of the paint:

- Flow Enhancers: Improve the leveling of the paint, reducing brush marks or orange peel.

- UV Absorbers: Protect the paint from fading due to sunlight.

- Flex Agents: Increase the flexibility of the paint, preventing cracking on flexible surfaces.

- Matting Agents: Reduce the gloss of the paint, creating a matte or satin finish.

Clearcoat: Protection and Gloss

A clearcoat is a transparent layer applied over the basecoat (the silver paint). It protects the basecoat from damage and provides a glossy finish. Clearcoats are typically urethane-based for automotive applications.

How It Works: The Alchemy of Silver

The magic of silver paint lies in the alignment and reflection of light off the aluminum flakes. Here's a simplified breakdown:

- Mixing: The pigments, binder, solvent, and additives are thoroughly mixed to create a homogenous paint. The ratio of aluminum flakes to gray pigment is crucial in determining the final silver shade.

- Application: The paint is applied in thin, even coats. The method of application (spraying, brushing, or rolling) affects the alignment of the aluminum flakes. Spraying generally provides the most even and metallic finish.

- Alignment: As the solvent evaporates, the aluminum flakes tend to align themselves parallel to the surface. This alignment is critical for reflecting light uniformly and creating the metallic shimmer. Some paints contain additives that promote flake alignment.

- Clearcoating: After the basecoat is dry, a clearcoat is applied. The clearcoat fills in any imperfections and protects the basecoat from environmental factors.

- Curing: The paint and clearcoat are allowed to cure, which involves the cross-linking of the binder molecules to form a hard, durable film. Curing can be accelerated with heat.

Real-World Use: Basic Troubleshooting

Here are some common issues you might encounter and how to address them:

- Orange Peel: This is a bumpy surface caused by the paint not leveling properly. It can be caused by improper thinning, incorrect spray technique, or using the wrong reducer. Try using a slower reducer or adjusting your spray gun settings.

- Runs or Sags: This happens when too much paint is applied in one area, causing it to run down the surface. Apply thinner coats and allow each coat to dry properly before applying the next.

- Fading or Discoloration: This is usually caused by UV exposure. Use a clearcoat with UV absorbers and park your car in the shade whenever possible.

- Poor Metallic Effect: This can be caused by improper mixing, incorrect application, or using the wrong type of aluminum flakes. Ensure the paint is thoroughly mixed, apply even coats, and use the recommended flake size for your desired finish.

- Color Mismatch after Repair: This can be caused by not mixing the paint according to the original factory formula. Most auto parts stores can mix custom paint based on your car's paint code.

Safety: Handle with Care

Paint and solvents can be hazardous. Always follow these safety precautions:

- Ventilation: Work in a well-ventilated area to avoid inhaling fumes. Use a respirator with organic vapor cartridges when spraying.

- Skin Protection: Wear gloves to protect your skin from contact with paint and solvents.

- Eye Protection: Wear safety glasses or a face shield to protect your eyes from splashes.

- Flammability: Many solvents are flammable. Keep away from open flames and sparks.

- Disposal: Dispose of paint and solvent waste properly according to local regulations. Never pour them down the drain. Improper disposal is an environmental hazard.

Specifically, pay extra attention when handling:

Isocyanates (often found in 2-part urethane clearcoats): These are highly reactive and can cause respiratory sensitization (asthma-like symptoms) with even brief exposure. Proper PPE (Personal Protective Equipment), including a supplied-air respirator, is essential when working with isocyanates.

Creating silver paint is a rewarding process that allows you to achieve a custom look for your vehicle. By understanding the components and techniques involved, you can troubleshoot common issues and ensure a professional-looking finish.

We have a detailed diagram outlining the mixing ratios and application techniques for several popular silver shades. Feel free to reach out, and we can provide you with the file for download.