How Does A All Wheel Drive Work

So, you're diving into the world of All-Wheel Drive (AWD). Good on you! Understanding how your AWD system works is invaluable, whether you're troubleshooting a noisy differential, planning some modifications, or just want to impress your buddies with your automotive knowledge. This guide will break down the complexities of a typical AWD system, arming you with the information you need to tackle repairs, diagnose issues, and appreciate the engineering marvel that keeps your wheels gripping.

Purpose: Why Understanding AWD Matters

Let's be clear: grasping the intricacies of your AWD system isn't just about bragging rights. It's about practical application. A solid understanding can save you significant money in the long run by allowing you to diagnose problems early, perform basic maintenance yourself, and avoid unnecessary trips to the mechanic. Furthermore, when modifying your vehicle for off-road performance or simply improving on-road handling, understanding how the AWD system distributes power is crucial for making informed decisions. Knowing the system’s limitations can also prevent costly damages. Think of it as preventative medicine for your drivetrain.

Key Specs and Main Parts: The AWD Anatomy

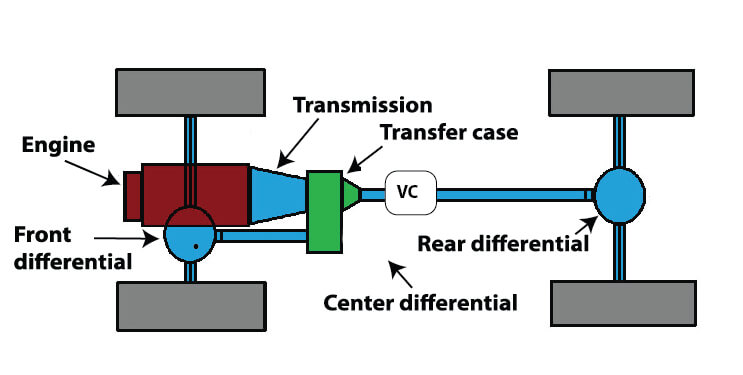

While AWD systems vary across manufacturers and models, the core components and principles remain consistent. Here’s a breakdown of the key players:

- Engine: The source of power, obviously. AWD systems rely on the engine to provide torque to all wheels.

- Transmission: Converts the engine's power into usable torque and speed, sending it to the drivetrain.

- Transfer Case: This is the heart of most AWD systems. It splits the power from the transmission between the front and rear axles. Some transfer cases use viscous couplings, others use electronic clutches, and some even have a lockable differential for extreme off-road conditions. The type of transfer case drastically affects how the AWD system behaves.

- Front Differential: Just like in a 2WD car, the front differential allows the front wheels to rotate at different speeds when turning. Without it, the inner wheel would drag, causing instability and tire wear.

- Rear Differential: Same function as the front differential, but for the rear wheels. Many AWD vehicles include a limited-slip differential (LSD) or electronically controlled differential in the rear (or both axles) to enhance traction.

- Drive Shafts (or Propeller Shafts): These connect the transfer case to the front and rear differentials, transmitting the rotational power.

- Axles: The final link in the chain, transferring power from the differentials to the wheels.

- Wheel Speed Sensors: Part of the ABS system, these sensors also provide data to the AWD control module, allowing it to detect wheel slip and adjust power distribution accordingly.

- AWD Control Module (ECU): The brain of the operation. It receives data from various sensors (wheel speed, throttle position, steering angle, etc.) and uses that information to control the transfer case and differentials, optimizing traction.

Symbols and Lines: Reading the AWD Diagram

When looking at an AWD diagram (which you can download at the end of this article!), pay close attention to the lines and symbols. Here's a quick guide:

- Solid Lines: Typically represent mechanical connections, like drive shafts. Thicker lines often indicate major components.

- Dashed Lines: Usually represent electronic connections, such as wiring harnesses connecting sensors to the control module.

- Arrows: Indicate the direction of power flow or movement. Pay attention to the arrowhead shape; it can denote specific types of movement (e.g., rotational vs. linear).

- Rectangles: Commonly used to represent electronic control units (ECUs) or sensors.

- Circles: Often depict gears or rotating components.

- Colors: Different colors might be used to differentiate between various types of fluids (e.g., transmission fluid, differential fluid) or electrical signals. There isn't a universal standard for colors, so always refer to the diagram's legend.

How It Works: Power Distribution

The core concept of AWD is to distribute engine torque to all four wheels, maximizing traction, especially on slippery surfaces. The specific mechanism varies depending on the AWD system type.

Full-Time AWD: These systems constantly send power to all four wheels. Some use a center differential or viscous coupling to allow for slight variations in wheel speed between the front and rear axles. This prevents driveline binding, which can occur when wheels need to rotate at different speeds during cornering. Some use clutch packs and electronically control the power split.

Part-Time AWD: These systems are typically engaged manually, often using a lever or button. They lock the front and rear axles together, providing maximum traction in low-grip situations. However, part-time AWD should only be used on loose surfaces (dirt, gravel, snow) because the lack of a center differential can cause driveline windup and damage on pavement.

Automatic (On-Demand) AWD: These systems typically operate in two-wheel drive under normal conditions, but automatically engage all-wheel drive when wheel slip is detected. They use sensors and a control module to monitor wheel speed and traction, and then engage the AWD system using a clutch pack, viscous coupling, or other mechanism. This type of AWD is often found in SUVs and crossovers.

The key difference between these types lies in how and when power is sent to all four wheels. Understanding which type your vehicle has is essential for proper operation and maintenance.

Real-World Use: Basic Troubleshooting

Here are some common AWD issues and basic troubleshooting steps:

- Vibrations: Could indicate a worn U-joint in the drive shaft, an unbalanced drive shaft, or a problem with a differential. Visually inspect the drive shafts for damage and check the U-joints for play.

- Noises (Clunking, Grinding): Could be a sign of a failing differential, transfer case, or CV joint. Check fluid levels in the differentials and transfer case. Listen for the noise's location to pinpoint the problem area.

- Warning Lights: A lit AWD warning light indicates a problem with the system. Use an OBD-II scanner to retrieve the diagnostic trouble code (DTC). This code will provide valuable information about the nature of the problem.

- Poor Traction: Could be due to worn tires, a malfunctioning AWD system, or a problem with the traction control system. Check tire pressure and tread depth. If the problem persists, have the AWD system diagnosed.

Important: Always consult your vehicle's repair manual for specific troubleshooting procedures and torque specifications.

Safety: Risky Components

Working on an AWD system involves several safety considerations:

- Driveline Windup: As mentioned earlier, forcing a part-time AWD system to operate on dry pavement can cause significant stress on the drivetrain. This can lead to component failure and even loss of control.

- High Torque: The drivetrain components of an AWD system are subjected to high torque. Using the correct tools and torque specifications is crucial to prevent damage and ensure proper function.

- Rotating Parts: Always disconnect the battery and ensure the vehicle is properly supported before working near rotating parts like drive shafts and axles.

- Fluid Hazards: Differential and transfer case fluids can be harmful if ingested or come into contact with skin. Wear gloves and eye protection when handling these fluids.

When in doubt, consult a qualified mechanic. Some AWD repairs require specialized tools and knowledge. Don’t risk damaging your vehicle or injuring yourself by attempting repairs beyond your skill level.

We've covered a lot here! Remember, the specific design and operation of your AWD system will vary depending on your vehicle's make and model. Always refer to your vehicle's service manual for detailed information and specific instructions.

Ready to get hands-on? You can download a simplified AWD system diagram here: [Link to Downloadable Diagram - Placeholder. This would need to be replaced with a real link]. This diagram will help you visualize the components and their relationships, making troubleshooting and repairs much easier.