How Does A Car Spoiler Work

Understanding Car Spoilers: Aerodynamics for the DIY Enthusiast

Whether you're enhancing your car's performance on the track or simply aiming for a more aggressive aesthetic, understanding how a spoiler works is crucial. This isn't just about bolting on a fancy piece of plastic; it's about manipulating airflow to improve handling and stability, especially at higher speeds. This guide breaks down the mechanics of car spoilers, providing you with the knowledge to make informed decisions about modifications and upgrades. This information will also be invaluable if you are considering repairing or replacing an existing spoiler or even designing a custom one.

Key Specs and Main Parts

A spoiler, also known as an air dam or rear wing depending on its specific design and location, is designed to alter the aerodynamic characteristics of a vehicle. The main parts of a typical rear spoiler include:

- Spoiler Blade (Wing): The main surface that interacts with the airflow. Its shape, angle of attack, and overall area are crucial factors determining its effectiveness.

- End Plates: Vertical surfaces at the ends of the spoiler blade. These help to reduce wingtip vortices (explained later) and maintain consistent airflow across the spoiler's surface.

- Stanchions (Mounting Brackets): The support structures that connect the spoiler blade to the vehicle's body. Their height and angle influence the spoiler's position relative to the airflow.

Key specifications to consider when evaluating a spoiler include:

- Angle of Attack: The angle between the spoiler blade and the oncoming airflow. Increasing the angle of attack generally increases downforce, but also drag.

- Chord Length: The width of the spoiler blade, measured from the leading edge to the trailing edge.

- Aspect Ratio: The ratio of the spoiler's span (width) to its chord length. Higher aspect ratios generally result in more efficient downforce generation.

- Material: Common materials include ABS plastic, fiberglass, carbon fiber, and aluminum. Each offers different strength-to-weight ratios and aesthetic qualities.

How It Works: Aerodynamics Explained

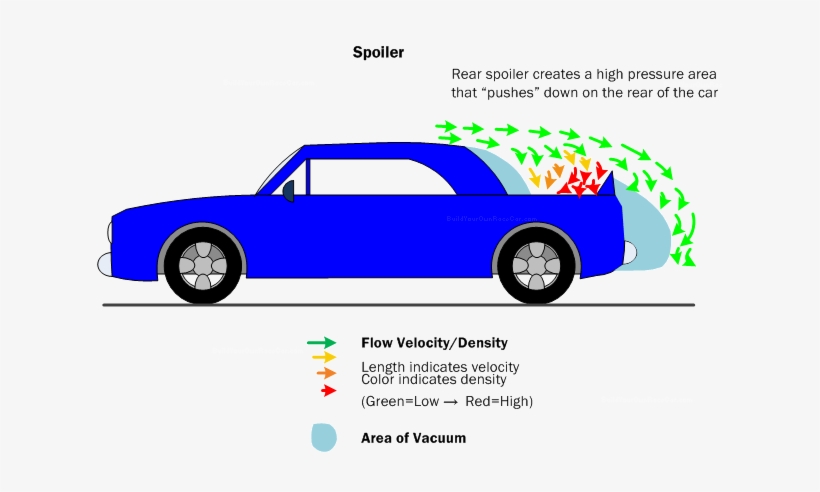

The fundamental principle behind a spoiler's operation is the manipulation of air pressure. As a car moves through the air, it creates areas of high and low pressure around its body. A spoiler is strategically positioned to disrupt this natural airflow and generate downforce – a downward force that presses the tires onto the road surface.

Here's a breakdown of the aerodynamic principles at play:

- Bernoulli's Principle: This principle states that faster-moving air has lower pressure. Spoilers are designed to create faster airflow over their upper surface and slower airflow underneath. This pressure differential generates a net downward force.

- Angle of Attack and Downforce: Increasing the angle of attack forces more air to travel over the top surface of the spoiler, further increasing the speed differential and generating more downforce. However, beyond a certain point, the airflow can stall (separate from the surface), drastically reducing downforce and increasing drag.

- Wingtip Vortices: At the tips of the spoiler, high-pressure air from underneath can curl around to the low-pressure area on top, creating swirling vortices. These vortices increase drag and reduce the spoiler's overall efficiency. End plates are used to minimize these vortices.

- Drag: While downforce is beneficial for handling, it comes at the cost of increased drag – resistance to motion through the air. More downforce typically means more drag, which can reduce top speed and fuel efficiency. The goal is to find the right balance between downforce and drag for the intended application.

Spoilers don't just create downforce; they can also improve aerodynamic efficiency by reducing lift. Lift is an upward force that can reduce tire grip, especially at high speeds. By counteracting lift, spoilers help to keep the car stable and predictable.

Real-World Use: Basic Troubleshooting

Here are some common issues you might encounter with your spoiler and how to address them:

- Spoiler Loosening or Detaching: This is a common issue, especially with aftermarket spoilers. Regularly inspect the mounting brackets and hardware for corrosion, cracks, or loose connections. Use thread locker (e.g., Loctite) on bolts to prevent them from loosening due to vibration.

- Paint Chipping or Cracking: Spoilers are exposed to harsh weather conditions and road debris, which can damage the paint. Regularly clean and wax your spoiler to protect the finish. Consider using a clear bra or paint protection film to prevent chipping.

- Reduced Fuel Efficiency: If you notice a significant drop in fuel economy after installing a spoiler, it may be generating excessive drag. Consider adjusting the angle of attack or switching to a more aerodynamic spoiler design.

- Vibrations or Noise: Loose mounting hardware or a poorly designed spoiler can cause vibrations and noise at high speeds. Tighten all connections and inspect the spoiler for any signs of damage or warping.

Note: If you experience significant changes in handling or stability after installing or adjusting a spoiler, consult with a qualified mechanic or aerodynamic specialist. Improperly designed or installed spoilers can negatively affect vehicle performance and safety.

Safety Considerations

Working with car spoilers involves some inherent risks:

- Sharp Edges: Spoilers, especially those made from carbon fiber or fiberglass, can have sharp edges. Wear gloves and eye protection when handling them.

- Drilling and Cutting: Installing a spoiler often requires drilling holes in the vehicle's body. Use appropriate safety gear (eye protection, gloves, ear protection) and follow proper drilling techniques. Be extremely careful not to damage wiring or fuel lines.

- Lifting and Positioning: Spoilers can be bulky and awkward to handle. Get assistance when lifting and positioning them to avoid injury.

- Torque Specifications: Always use the correct torque specifications when tightening mounting hardware. Over-tightening can damage the spoiler or the vehicle's body.

The most risky components are the areas where you are potentially altering the vehicle's structure. Take great care when drilling or modifying the car's body, ensuring you are not compromising its structural integrity or damaging vital systems.

Furthermore, always ensure your spoiler is securely attached. A spoiler that detaches at high speed can be a serious hazard to yourself and other drivers.

We have a detailed diagram of a typical car spoiler, including labeled parts and airflow patterns, available for download. This diagram will further enhance your understanding of spoiler mechanics and aid in repairs or modifications. Understanding the complexities of airflow over a car spoiler is crucial for anyone seeking to improve their vehicle's aerodynamics. By paying attention to angle of attack, chord length, and other key specs, DIYers can confidently install or modify spoilers to boost their car's performance.