How Does A Cvt Transmission Work

So, you're curious about CVTs, eh? Good on you! Continuously Variable Transmissions (CVTs) are becoming increasingly common, and understanding how they tick can be a real asset whether you're planning some DIY maintenance, troubleshooting issues, or just want to be a more informed car owner. This article dives deep into the workings of a CVT, aiming to equip you with the knowledge you need to tackle common issues and understand the underlying technology.

Purpose of Understanding CVT Operation

Why bother understanding this? Well, knowledge is power. Understanding the CVT operation can help you:

- Diagnose problems more effectively. Instead of just replacing parts blindly, you'll know what to look for.

- Perform basic maintenance, such as fluid changes (though CVTs often require specific fluids!).

- Make informed decisions about aftermarket upgrades or repairs.

- Understand the limitations of your CVT, especially if you're considering performance modifications.

We're providing detailed insights here, and remember, we've got a schematic diagram available for download at the end to really bring this all together visually.

Key Specs and Main Parts

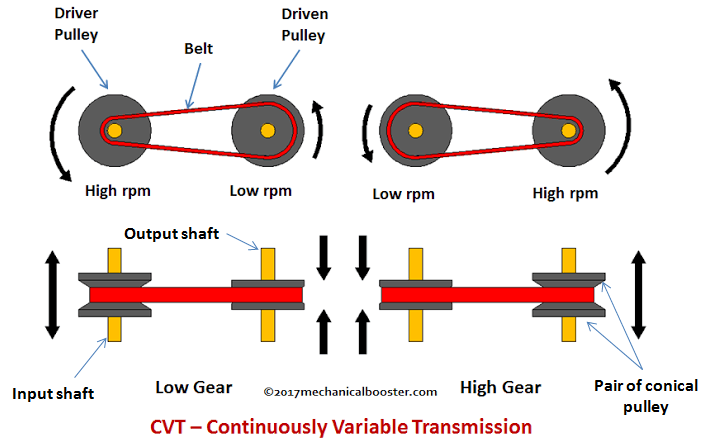

A CVT, unlike traditional automatic transmissions with fixed gear ratios, uses a system of pulleys and a belt or chain to provide a virtually infinite number of gear ratios within a specified range. Here are the key components:

Primary (Input) Pulley

Connected to the engine's crankshaft, the primary pulley receives the engine's power. Its diameter can be adjusted.

Secondary (Output) Pulley

Connected to the differential and ultimately the drive wheels, the secondary pulley transfers power to the drivetrain. Like the primary pulley, its diameter is adjustable.

Belt or Chain

A high-strength belt or chain (usually made of steel) connects the two pulleys. This belt/chain is the heart of the CVT, transmitting power between the pulleys.

Hydraulic Control System

A complex network of valves, solenoids, and sensors controls the hydraulic pressure that adjusts the pulley diameters. The Transmission Control Module (TCM) manages this system.

Transmission Control Module (TCM)

The TCM is the brain of the CVT, receiving data from various sensors (engine speed, vehicle speed, throttle position, etc.) and controlling the hydraulic system to adjust the gear ratio.

Forward/Reverse Gear Set

CVTs often include a separate forward/reverse gear set (planetary gear set) to allow the vehicle to move in both directions. This is similar to what you find in a standard automatic.

Key Specs: While not as clearly defined as in a geared transmission, CVTs have a ratio range (e.g., 2.5:1 to 0.5:1). This represents the highest and lowest gear ratios achievable. The torque capacity is also a crucial specification, indicating the maximum torque the CVT can handle without failure. Exceeding this limit can lead to belt slippage or other damage.

How It Works

The magic of a CVT lies in its ability to continuously vary the gear ratio. This is achieved by adjusting the effective diameter of the pulleys. Here’s the breakdown:

- Power Input: The engine spins the primary pulley.

- Ratio Adjustment: The TCM, based on driver input and sensor data, signals the hydraulic control system to adjust the pulley diameters.

- To achieve a lower gear ratio (for acceleration), the primary pulley's diameter is reduced, and the secondary pulley's diameter is increased. This allows the engine to operate at a higher RPM, delivering more power to the wheels.

- To achieve a higher gear ratio (for fuel efficiency at cruising speeds), the primary pulley's diameter is increased, and the secondary pulley's diameter is reduced. This allows the engine to operate at a lower RPM.

- Power Transfer: The belt or chain transmits the power from the primary pulley to the secondary pulley. The ratio between the pulley diameters determines the gear ratio.

- Output: The secondary pulley spins the differential, which distributes power to the drive wheels.

The continuous adjustment of the pulley diameters allows the CVT to maintain the engine at its optimal operating point (often the point of peak efficiency or peak power), resulting in improved fuel economy and smoother acceleration compared to traditional automatic transmissions. Because the pulleys are always changing in relation to the load, the CVT is constantly finding that sweet spot to make the engine run as smooth as possible.

Real-World Use and Basic Troubleshooting

While CVTs offer advantages, they can also experience problems. Here are a few basic troubleshooting tips:

- Slipping: A common symptom is slipping, where the engine revs up but the vehicle doesn't accelerate proportionally. This can be caused by a worn belt/chain, low or contaminated transmission fluid, or a faulty hydraulic control system.

- Shuddering: Shuddering or vibrations during acceleration can indicate a problem with the torque converter (if equipped), the belt/chain, or the pulleys.

- Noise: Unusual noises, such as whining or grinding, can be a sign of internal damage or wear.

- Fluid Leaks: Check for leaks around the transmission housing, seals, and cooler lines. Low fluid levels can cause serious damage.

- Error Codes: Use an OBD-II scanner to check for transmission-related error codes. These codes can provide valuable clues about the nature of the problem.

Important note: CVT fluid is often very specific. Using the wrong type of fluid can cause serious damage. Always consult your vehicle's owner's manual or a trusted mechanic before changing the fluid.

Safety Considerations

Working on a CVT can be risky. Here are a few safety precautions:

- High Pressure: The hydraulic system operates at high pressure. Never disconnect hydraulic lines while the engine is running or the system is pressurized.

- Hot Components: The transmission can get very hot during operation. Allow it to cool down completely before working on it.

- Heavy Components: The transmission is heavy. Use proper lifting equipment and techniques to avoid injury.

- Specific Fluids: As noted above, using the wrong fluid can be catastrophic. Double-check compatibility.

It is also important to disconnect the battery to prevent accidental activation of any electrical components.

Schematic Diagram

This article provides a solid foundation for understanding CVT operation. The detailed schematic diagram we have available offers a valuable visual aid. It highlights the flow of power, the operation of hydraulic system, and the connection between the key components, like the input and output pulley.

With our schematic, it’s as though you have an insider’s view of the CVT. You’ll be able to dive into the transmission and understand its function at its core. With the diagram in hand, you will have an easy reference point when you are troubleshooting.

So, go ahead and download the CVT schematic diagram for an even deeper dive into the topic. Good luck with your DIY endeavors!