How Does All Wheel Drive Work

Alright, let's dive deep into the fascinating world of All-Wheel Drive (AWD) systems. Understanding how AWD works is crucial, whether you're diagnosing a driveline issue, planning modifications for off-roading, or just want to impress your buddies with your automotive knowledge. This isn't just theoretical; knowing the inner workings can save you money on repairs and empower you to make informed decisions about your vehicle.

Key Specs and Main Parts

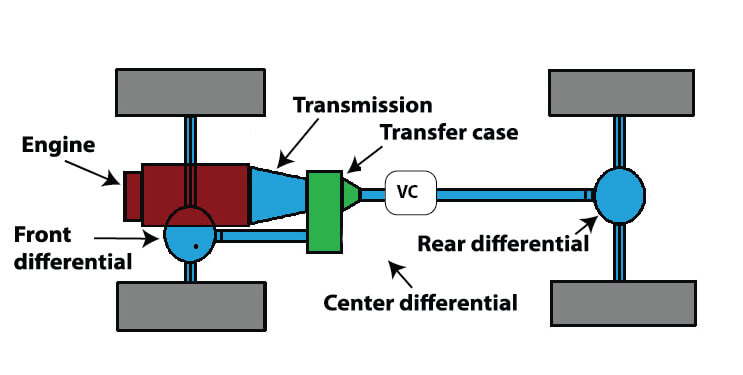

AWD systems aren't created equal. There's a whole spectrum, from simple part-time systems to sophisticated electronically controlled setups. Let's break down the key components you'll find across most AWD configurations:

- Engine: The source of power, obviously. The engine's output is measured in horsepower (power) and torque (twisting force).

- Transmission: This gearbox multiplies the engine's torque and allows the vehicle to operate at different speeds.

- Transfer Case: This is the heart of most AWD systems. Its primary function is to split the engine's torque between the front and rear axles. Some transfer cases offer low-range gearing for off-roading. We will touch on different types below.

- Front and Rear Differentials: These devices allow the wheels on each axle to rotate at different speeds, which is essential for turning. Without differentials, the inside wheel would have to skid during a turn, which could break the axle and cause poor control.

- Axle Shafts/Half Shafts: These connect the differentials to the wheels, transmitting the torque to spin them.

- Wheel Speed Sensors (WSS): Electronically controlled AWD systems often use WSS to detect wheel slip and adjust torque distribution accordingly.

- Electronic Control Unit (ECU): In advanced AWD systems, the ECU monitors various sensors (WSS, throttle position, steering angle, etc.) and controls the torque distribution based on pre-programmed algorithms.

Different Types of Transfer Cases

The transfer case is the unsung hero of AWD. Here are a few common types:

- Part-Time AWD: This is the simplest type, often found in older trucks and SUVs. It mechanically locks the front and rear axles together, providing maximum traction in low-grip situations. However, it should not be used on dry pavement because the lack of a center differential will cause driveline binding and potential damage.

- Full-Time AWD: These systems use a center differential (sometimes called an inter-axle differential) to allow the front and rear axles to rotate at different speeds. This allows for safe operation on both dry and slippery surfaces.

- Automatic AWD (also called On-Demand AWD): These systems typically operate in two-wheel drive (2WD) under normal conditions. When wheel slip is detected, the system automatically engages the front axle, providing AWD capability. These systems often use a viscous coupling or an electronically controlled clutch pack to transfer torque to the front axle.

Symbols Explained

When looking at diagrams of AWD systems, you'll encounter several common symbols:

- Solid Lines: Generally represent mechanical connections, such as shafts or gears.

- Dashed Lines: Often indicate hydraulic or pneumatic lines, especially in systems with clutch packs or actuators.

- Dotted Lines: Typically represent electrical wiring or control signals.

- Arrows: Show the direction of power flow or fluid flow.

- Gear Symbols: Represent gears within the transmission, transfer case, and differentials.

- Clutch Symbols: Show the location of clutches that engage or disengage power transfer.

How It Works

Let's break down the flow of power in a typical full-time AWD system with a center differential:

- The engine generates power, which is transmitted to the transmission.

- The transmission multiplies the torque and sends it to the transfer case.

- The transfer case splits the torque between the front and rear driveshafts. The center differential allows for different rotational speeds between the front and rear axles.

- The front and rear driveshafts deliver torque to the front and rear differentials, respectively.

- The differentials distribute torque to the wheels on each axle, allowing them to rotate at different speeds during turns.

- The wheels then propel the vehicle forward.

In an automatic AWD system, the process is similar, but the transfer case typically remains disengaged until wheel slip is detected. The ECU monitors the wheel speed sensors and, upon detecting a difference in speed between the front and rear wheels, engages a clutch pack or viscous coupling within the transfer case to send power to the front axle.

Electronic AWD systems are even more sophisticated. They can dynamically adjust the torque split between the front and rear axles (and even between individual wheels in some cases) based on various factors, such as throttle position, steering angle, yaw rate (the rate at which the vehicle is rotating), and road conditions. This allows for optimal traction and handling in a wide range of driving situations.

Real-World Use – Basic Troubleshooting Tips

Here are a few common AWD problems and troubleshooting steps:

- Binding or Vibrations (Part-Time AWD): This is usually a sign that you're driving in 4WD on dry pavement. Disengage the AWD system immediately. If the problem persists, it could indicate a damaged driveline component.

- AWD Warning Light: This indicates a problem with the AWD system. Have the system scanned for trouble codes using an OBD-II scanner. Common causes include faulty wheel speed sensors, actuator problems, or issues with the ECU.

- Reduced Fuel Economy: Constant engagement of the AWD system (especially in systems that are normally 2WD) can reduce fuel economy. Make sure the system is disengaging when it should.

- Unusual Noises: Grinding, clicking, or whining noises coming from the transfer case or differentials can indicate worn bearings, gears, or other internal damage.

Before attempting any repairs, consult your vehicle's service manual for specific procedures and torque specifications. Always disconnect the negative battery terminal before working on electrical components.

Safety – Highlight Risky Components

AWD systems contain several components that can be hazardous if not handled properly:

- Rotating Driveshafts: Never work on the driveline with the engine running or the vehicle in gear. Securely support the vehicle with jack stands before working underneath.

- Spring-Loaded Components: Some transfer cases and differentials contain spring-loaded components that can cause injury if disassembled improperly. Refer to the service manual for specific instructions.

- High-Voltage Electronics: Hybrid and electric vehicles with AWD systems may contain high-voltage components. Only qualified technicians should work on these systems.

- Heavy Components: Transfer cases and differentials are heavy and can cause injury if dropped. Use proper lifting techniques and equipment.

Always wear safety glasses and gloves when working on any automotive system. When in doubt, consult a qualified mechanic.

We have a detailed diagram of a typical AWD system available for download. It provides a visual representation of the components and their relationships. Click here to download the AWD system diagram. It's an invaluable resource for understanding the intricacies of these systems.