How Does An Electric Engine Work

Alright, let's dive into the fascinating world of electric motors – the heart of any electric vehicle (EV). This explanation isn't just academic; understanding how your EV's motor works is crucial for troubleshooting minor issues, appreciating its design, and even planning potential modifications down the line. While internal combustion engines are complex, electric motors have their own unique set of principles. Having a grasp of these principles empowers you to be a more informed EV owner or modifier.

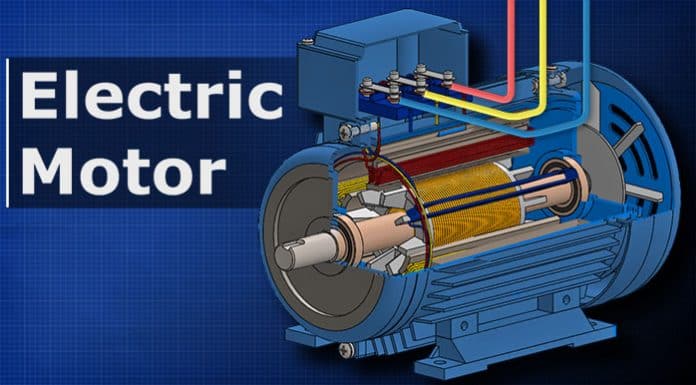

Key Specs and Main Parts

Electric motors, despite their varying designs, share some core components and specifications. Let's break them down:

- Stator: The stationary part of the motor. Think of it as the house. It contains the windings that create the magnetic field.

- Rotor: The rotating part of the motor, driven by the magnetic field generated by the stator. This is where the power is translated into rotational motion.

- Windings: Coils of wire within the stator (and sometimes the rotor) that carry electrical current. The arrangement and number of windings directly impact the motor's characteristics.

- Commutator (DC motors only): A segmented ring that reverses the current direction in the rotor windings, keeping the motor spinning in the correct direction. AC motors don't typically have commutators.

- Brushes (DC motors only): Conductive pads that make contact with the commutator, providing a path for current to flow to the rotor windings. These wear down over time and are a common maintenance item in brushed DC motors.

- Bearings: Support the rotor and allow it to spin freely with minimal friction.

- Controller/Inverter: The brain of the operation! It regulates the amount of power delivered to the motor, controls its speed and torque, and handles regenerative braking (where applicable). In EVs, this typically involves converting DC power from the battery to AC power for the motor.

- Housing: The physical enclosure that protects the motor's internal components.

Key Specifications to Know:

- Voltage (V): The electrical potential difference required to operate the motor. Higher voltage often allows for greater power output.

- Current (A): The amount of electrical charge flowing through the motor. Higher current often corresponds to higher torque.

- Power (kW or HP): The rate at which the motor performs work. A higher power rating means the motor can deliver more torque at higher speeds.

- Torque (Nm or lb-ft): A measure of the motor's rotational force. Higher torque means the motor can accelerate faster and climb steeper hills.

- Speed (RPM): The rotational speed of the motor, measured in revolutions per minute.

- Efficiency (%): The ratio of mechanical power output to electrical power input. A higher efficiency rating means the motor wastes less energy as heat.

Symbols and Diagram Conventions

Understanding the conventions used in electrical diagrams is essential. Here's a quick rundown:

- Solid Lines: Represent electrical conductors (wires).

- Dotted Lines: Often indicate mechanical linkages or control signals.

- Circles with an 'M': Typically represent a motor.

- Resistor Symbol (zigzag line): Represents a resistor, an electrical component that opposes the flow of current.

- Capacitor Symbol (two parallel lines): Represents a capacitor, an electrical component that stores electrical energy.

- Ground Symbol (series of horizontal lines getting smaller): Represents the electrical ground, a reference point with zero voltage.

- Color Coding: While not always standardized, common conventions include:

- Red: Positive (+) voltage.

- Black: Negative (-) voltage or ground.

- Blue/Green: Control signals or auxiliary circuits.

How It Works: The Electromagnetism Principle

The fundamental principle behind electric motor operation is electromagnetism. Here's the core idea:

A current-carrying conductor placed in a magnetic field experiences a force.

This force is what makes the motor spin. Let's break down how this happens in a typical AC induction motor (the most common type in EVs):

- AC Power Input: Three-phase alternating current (AC) is supplied to the stator windings. Three-phase power delivers a more constant power flow than single-phase.

- Rotating Magnetic Field: The AC current flowing through the stator windings creates a rotating magnetic field. The frequency of the AC current determines the speed of the rotating field.

- Induced Current in Rotor: This rotating magnetic field cuts across the rotor windings (which are often "squirrel cage" shaped – shorted conductors). According to Faraday's Law of Induction, this induces a current in the rotor windings.

- Force and Rotation: The induced current in the rotor windings creates its own magnetic field. This rotor magnetic field interacts with the stator's rotating magnetic field, creating a force that causes the rotor to rotate. The rotor "chases" the rotating magnetic field of the stator, but always lags slightly behind. This difference in speed is called "slip".

The controller/inverter plays a vital role in adjusting the frequency and amplitude of the AC power supplied to the stator. By changing the frequency, the controller can control the speed of the rotating magnetic field, and thus, the speed of the motor. By changing the amplitude (voltage), the controller can control the torque output of the motor.

Different types of electric motors (e.g., permanent magnet synchronous motors – PMSM) operate on slightly different principles, but the core concept of electromagnetism remains the same. PMSMs, for example, use permanent magnets in the rotor, which simplifies the induction process but requires precise control of the stator current to maintain efficiency.

Real-World Use and Basic Troubleshooting

Knowing how your motor works helps you diagnose problems. Here are a few common issues and potential causes:

- Motor Not Starting:

- Problem: Motor doesn't turn on at all.

- Possible Causes: Blown fuse, faulty controller/inverter, wiring problem, damaged motor windings, emergency stop engaged.

- Motor Overheating:

- Problem: Motor gets excessively hot during operation.

- Possible Causes: Overload, insufficient cooling (fans not working, blocked vents), damaged motor windings, high ambient temperature.

- Reduced Performance:

- Problem: Motor delivers less power or torque than usual.

- Possible Causes: Degraded battery, faulty controller/inverter, worn motor bearings, partial short in windings.

- Unusual Noises:

- Problem: Motor makes strange sounds (e.g., grinding, squealing).

- Possible Causes: Worn motor bearings, loose components, foreign object in the motor.

Important Note: Always start with the simplest checks first. Check fuses, wiring connections, and cooling fans before assuming a major component failure. Many EVs have built-in diagnostics that can help pinpoint the source of the problem.

Safety First!

Working with electric motors, especially in EVs, involves high voltages and currents. Safety is paramount!

- High Voltage Components: The battery pack, controller/inverter, and motor windings all operate at potentially lethal voltages. Never work on these components unless you are properly trained and have the correct safety equipment (e.g., high-voltage gloves, insulated tools).

- Capacitors: The controller/inverter contains large capacitors that can store a dangerous charge even after the vehicle has been turned off. Always discharge capacitors properly before working on the controller/inverter.

- Lockout/Tagout: Before working on any electrical components, disconnect the battery pack and use a lockout/tagout procedure to prevent accidental re-energization.

Do not underestimate the dangers of working with high-voltage electrical systems. If you are unsure about any procedure, consult a qualified EV technician.

Understanding the inner workings of your EV's motor can unlock a new level of appreciation and competence. By familiarizing yourself with the components, principles, and potential problems, you'll be better equipped to maintain and troubleshoot your vehicle. Remember safety comes first!

We have a detailed diagram of a typical EV motor and its control system available for download. It provides a visual representation of the concepts we've discussed here, making it even easier to understand. It's a valuable resource for anyone wanting to delve deeper into EV technology. You can find it by clicking the link below. Happy motoring!