How Does Front Wheel Drive Work

Welcome, gearheads! You're probably here because you're diving deeper into the mechanical mysteries of your front-wheel-drive (FWD) vehicle. Maybe you're planning a repair, thinking about modifications, or just want to understand how your car *really* works. This article will give you a solid technical understanding of FWD systems, acting as a companion guide to the detailed diagram we've prepared for you to download (link at the end!). Knowing the inner workings of your FWD system empowers you to diagnose issues, perform basic maintenance, and even make informed decisions about upgrades. Let's get started.

Key Specs and Main Parts of a Front-Wheel-Drive System

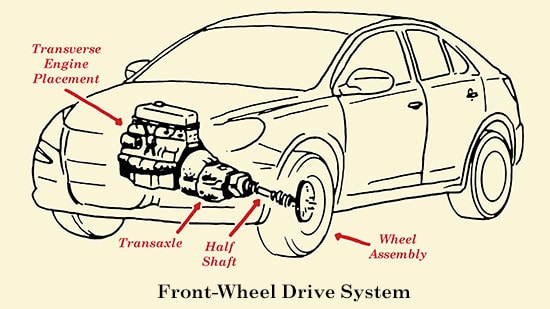

Before we dive into the mechanics, let's define the core components. FWD systems combine the engine, transmission, and drivetrain into a single unit, saving space and weight. Here are the key players:

- Engine: The power source, converting fuel into mechanical energy. We won't delve into engine internals here, but understanding its connection to the transmission is crucial.

- Transmission (Transaxle): This is a critical component in a FWD car.

A conventional transmission uses gears to convert the engine's output into usable power for the wheels. In a FWD vehicle, the transmission is often combined with the final drive and differential into a single unit called a transaxle. This saves space and weight, which are both important considerations in smaller vehicles. The transaxle performs the same function as a transmission in a RWD car, but it is located at the front of the vehicle and directly connected to the front wheels.

- Differential: This allows the front wheels to rotate at different speeds when turning. Without it, the inside wheel would have to drag during turns, causing tire wear and making the car difficult to handle.

- Driveshafts (Half-shafts): These transfer power from the differential to the front wheels. They must be flexible enough to accommodate suspension movement and steering angles. Constant Velocity (CV) joints are critical components of the driveshaft.

- CV Joints (Constant Velocity Joints): Located at both ends of the driveshafts, these joints allow the driveshaft to transmit power smoothly, regardless of the angle of the joint. There are two main types: the inner CV joint, which accommodates changes in length due to suspension movement, and the outer CV joint, which accommodates steering angles.

- Wheel Hubs: The mounting point for the wheels and brake rotors.

Understanding Symbols in Our FWD Diagram

Our downloadable diagram uses standard engineering symbols. Here's a quick guide:

- Solid Lines: Typically represent physical connections, such as shafts or fluid lines.

- Dashed Lines: Often indicate control signals or less direct relationships. For example, a dashed line might show the connection between a sensor and the engine control unit (ECU).

- Colors: Colors may vary, but generally, red indicates high-pressure fluid lines (like those in the braking system), blue represents coolant, and yellow signifies electrical connections. Consult the specific diagram legend for definitive color coding.

- Icons: Specific symbols represent components like gears, bearings, and sensors. A rectangle with a sine wave inside might indicate a sensor, while meshed gears represent gear sets. Again, refer to the diagram's legend for precise interpretation.

How Front-Wheel Drive Works: A Step-by-Step Explanation

Here's the breakdown of how power flows in a FWD system:

- Engine Output: The engine generates power in the form of rotational energy (torque).

- Transmission Engagement: The engine's torque is delivered to the transmission via the flywheel and clutch (in manual transmissions) or the torque converter (in automatic transmissions).

- Gear Selection: The driver (or the transmission's control system in an automatic) selects a gear ratio within the transmission. This changes the torque and speed of the output shaft. Lower gears provide more torque for acceleration, while higher gears offer better fuel economy at cruising speeds.

- Power Transfer to the Differential: The transmission's output shaft is connected to the differential. The differential's primary purpose is to allow the front wheels to rotate at different speeds during turns.

- Differential Splits Torque: The differential splits the torque from the transmission and directs it to the two driveshafts.

- Driveshaft Transmission: Each driveshaft transmits power from the differential to its respective front wheel. The CV joints allow the driveshafts to operate smoothly despite the changing angles caused by steering and suspension movement.

- Wheel Rotation: Finally, the power is transferred to the wheel hubs, causing the wheels to rotate and propel the vehicle forward.

The crucial point is that everything happens at the front of the vehicle. The engine, transmission, and differential are all packaged together, making for a compact and efficient system. This configuration also offers advantages in terms of weight distribution, often placing more weight over the driven wheels, improving traction, especially in slippery conditions. However, this can also lead to torque steer, which is the tendency of the steering wheel to pull to one side during hard acceleration.

Real-World Use: Basic Troubleshooting Tips for FWD Systems

Here are a few common problems and how to approach them:

- Clicking Noise During Turns: This is a classic sign of a failing CV joint. The protective boot around the joint may be torn, allowing grease to escape and contaminants to enter. You'll likely need to replace the entire driveshaft assembly.

- Vibrations at High Speeds: This could indicate a number of issues, including unbalanced tires, bent wheels, or worn CV joints. Start by having your tires balanced. If the vibration persists, inspect the driveshafts for damage and check the CV joints for excessive play.

- Fluid Leaks: Check for leaks around the transmission or differential. Leaks can lead to low fluid levels, which can cause serious damage to the transmission. Identify the type of fluid leaking (transmission fluid is typically red or brown, while engine oil is black) to pinpoint the source of the leak.

- Torque Steer: Excessive torque steer can be caused by uneven tire wear, misaligned suspension, or worn suspension components. Ensure your tires are properly inflated and rotated regularly, and have your suspension checked for alignment and wear.

Safety Considerations

Working on a FWD system involves potential hazards. Here are some important safety precautions:

- Supporting the Vehicle: Always use jack stands when working under a vehicle. Never rely solely on a jack.

- Disconnecting the Battery: Disconnect the negative battery terminal before working on any electrical components.

- Handling Fluids: Transmission fluid and other automotive fluids can be harmful. Wear gloves and eye protection when handling them. Dispose of fluids properly according to local regulations.

- CV Joint Grease: CV joint grease can be messy and can stain clothing. Use caution when handling driveshafts and CV joints.

- Torque Specifications: Always use a torque wrench and follow the manufacturer's torque specifications when tightening bolts. Over-tightening can damage components, while under-tightening can lead to loosening and failure.

The most critical safety precaution is never to work on a vehicle that is only supported by a jack. Always use jack stands appropriately rated for the vehicle's weight. The OSHA guidelines for motor vehicle repair are a good resource to become familiar with.

Remember, this article provides a general overview. Refer to your vehicle's service manual for specific procedures and torque specifications. If you're unsure about any aspect of the repair, consult a qualified mechanic.

Now, put this knowledge to good use! You can download the detailed FWD system diagram here. Good luck, and happy wrenching!