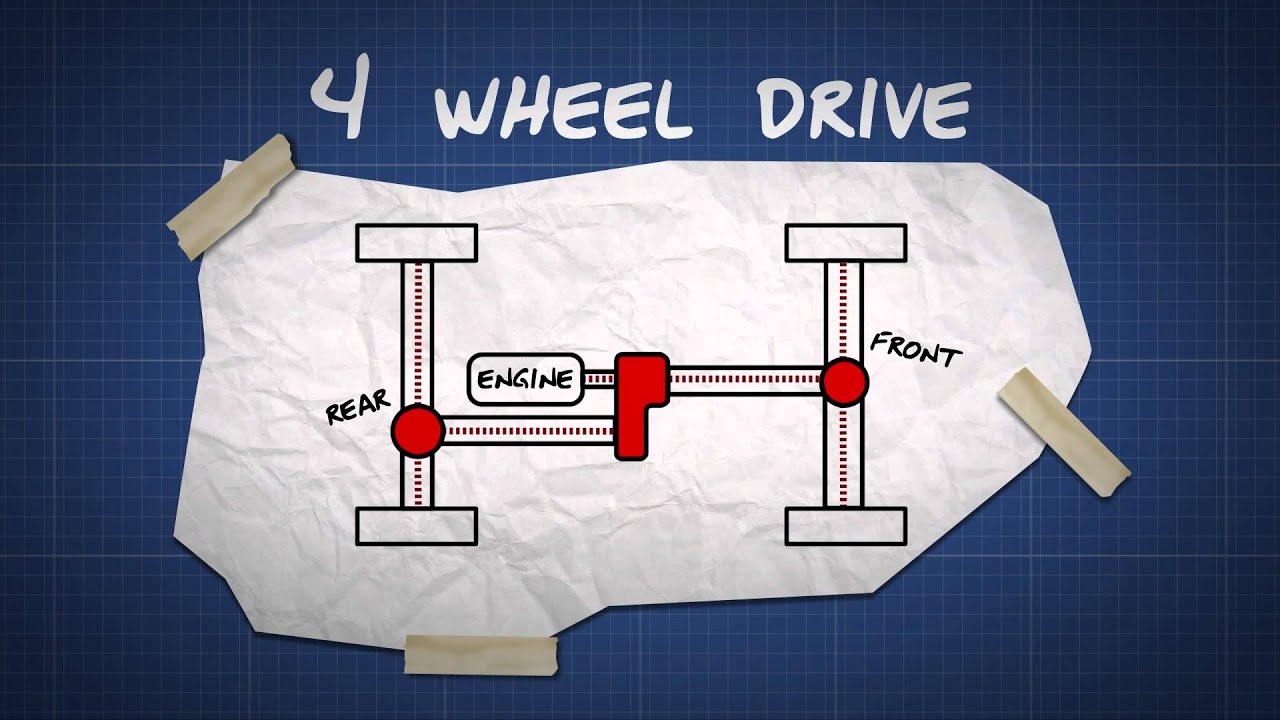

How Does The 4 Wheel Drive Work

Alright, let's dive into the fascinating world of 4-Wheel Drive (4WD) systems. This isn't just about slapping a sticker on your truck; it's a complex interaction of mechanical components that deliver power to all four wheels. Understanding how your 4WD system works is crucial whether you're tackling off-road trails, performing your own maintenance, troubleshooting issues, or even considering aftermarket upgrades. With a good grasp of the fundamentals, you can diagnose problems more effectively, make informed decisions about modifications, and potentially save yourself a lot of money on costly repairs. We're assuming you've got some wrenching experience and a decent understanding of automotive basics – this isn't a beginner's guide, but we'll break things down in a clear and approachable way.

Key Specs and Main Parts of a 4WD System

Before we get into the nitty-gritty, let’s lay out the major components you'll find in a typical 4WD system:

- Engine: The source of all the power, obviously!

- Transmission: The gearbox that multiplies the engine's torque and provides different gear ratios for varying speeds and loads.

- Transfer Case: The heart of the 4WD system. This unit splits power between the front and rear axles. It also often contains low-range gearing for serious off-roading. Think of it as a second, smaller transmission that lives between the main transmission and the axles.

- Front and Rear Driveshafts: Rotating shafts that transmit power from the transfer case to the front and rear differentials.

- Front and Rear Differentials: These units allow each wheel on an axle to rotate at different speeds, which is essential for turning corners. Without them, your wheels would bind up and make turning almost impossible. Differentials contain gears that distribute torque while allowing for speed differences.

- Axle Shafts (Half-shafts): Connect the differential to the wheels, transmitting the final drive torque.

- Hubs (or Locking Hubs): In some older or part-time 4WD systems, locking hubs are used to physically connect the front wheels to the axle shafts. This allows the driver to disengage the front axle for better fuel economy and reduced wear when 4WD is not needed. Newer systems often use automatic engagement mechanisms, but the principle remains the same.

Key Specs to consider when discussing 4WD systems include:

- Gear Ratios: The ratio of engine rotations to wheel rotations in different gears, especially in low range. A lower (numerically higher) ratio provides more torque for climbing or crawling.

- Torque Split: The percentage of torque sent to the front and rear axles. This can be fixed (e.g., 50/50) or variable, depending on the system.

- Locking Mechanism: Whether the system uses open differentials, limited-slip differentials, or locking differentials. Open differentials allow for maximum wheel speed difference, while locking differentials force both wheels on an axle to turn at the same speed. Limited-slip differentials offer a compromise between the two.

Understanding the 4WD Diagram: Symbols and Conventions

A typical 4WD system diagram will use standard symbols to represent the various components. Here's a breakdown of some common conventions:

- Solid Lines: Usually represent mechanical connections or shafts that transmit power. A thicker line might indicate a larger or stronger shaft.

- Dashed Lines: Often indicate control lines, such as vacuum lines, electrical wires, or hydraulic lines that activate actuators or switches.

- Colors: Colors can vary depending on the diagram's purpose, but generally:

- Red: Might indicate a high-pressure or high-voltage line.

- Blue: Might represent a low-pressure or sensor signal line.

- Green: Might indicate a ground or return path.

- Gear Symbols: Gears are typically represented by meshed circles or stylized tooth profiles. The number of teeth might be indicated to show gear ratios.

- Differential Symbols: Differentials are often represented by a circle with a cross or other internal symbol to indicate the gear arrangement.

- Actuator Symbols: Actuators (electric motors, vacuum diaphragms, etc.) are often depicted as boxes or cylinders with connecting lines to indicate their control mechanisms.

It's crucial to consult the specific legend provided with the diagram you're using, as conventions can vary slightly. A factory service manual will be your best resource for accurate and detailed diagrams.

How 4WD Works: A Step-by-Step Explanation

The fundamental principle of 4WD is simple: distribute engine power to all four wheels instead of just two. However, the implementation can vary significantly. Let's walk through the power flow in a common part-time 4WD system:

- Power Generation: The engine generates power, which is measured in horsepower (hp) and torque (lb-ft).

- Torque Multiplication: The transmission multiplies the engine's torque, allowing the vehicle to overcome inertia and climb steep inclines. The selected gear determines the amount of torque multiplication.

- Power Split: The transfer case receives power from the transmission and splits it between the front and rear driveshafts. In 2WD mode, the transfer case typically disengages the front driveshaft, sending all power to the rear axle. In 4WD mode, the transfer case locks the front and rear driveshafts together, forcing them to rotate at the same speed.

- Power Transmission: The driveshafts transmit power from the transfer case to the front and rear differentials.

- Differential Action: The differentials allow the wheels on each axle to rotate at different speeds when cornering. This is crucial for on-road driving, as the outside wheel travels a greater distance than the inside wheel during a turn.

- Wheel Rotation: Finally, the axle shafts (or half-shafts) transmit the torque from the differentials to the wheels, causing them to rotate and propel the vehicle.

Important Note: Part-time 4WD systems are designed for off-road use and should not be engaged on paved roads with good traction. When all four wheels are forced to rotate at the same speed on a high-traction surface, the driveline can bind up, potentially causing damage to the transfer case, differentials, or axles. Full-time 4WD systems, on the other hand, utilize a center differential in the transfer case to allow for speed differences between the front and rear axles, making them suitable for on-road use in all conditions.

Real-World Use and Basic Troubleshooting

Here are some basic troubleshooting tips for common 4WD problems:

- Difficulty Shifting into 4WD: This could be due to a stuck shift linkage, a faulty actuator (electric or vacuum), or a problem with the transfer case itself. Try rocking the vehicle back and forth while attempting to shift. Check vacuum lines for leaks if applicable.

- Grinding Noises: Grinding noises in 4WD can indicate worn gears in the transfer case or differentials. Check the fluid levels and condition in these components. If the fluid is contaminated with metal shavings, it's a sign of serious wear.

- Vibrations in 4WD: Vibrations can be caused by unbalanced driveshafts, worn U-joints, or loose components. Inspect the driveshafts for damage and ensure that all U-joints are properly lubricated.

- Hub Issues: If you have manual locking hubs, make sure they are properly engaged. Automatic locking hubs can sometimes fail to engage or disengage correctly.

Pro Tip: Regular maintenance is key to preventing 4WD problems. Change the fluid in your transfer case and differentials according to the manufacturer's recommendations. Inspect your driveshafts and U-joints regularly for wear and damage.

Safety Considerations

Working on a 4WD system can be dangerous if you're not careful. Here are some key safety precautions:

- Disconnect the Battery: Before working on any electrical components, disconnect the negative battery cable to prevent accidental shorts or shocks.

- Support the Vehicle Properly: Never work under a vehicle supported only by a jack. Use jack stands to provide secure support.

- Be Aware of Rotating Parts: Keep your hands and clothing away from rotating parts, especially when the engine is running.

- Handle Fluids Carefully: Gear oil and other automotive fluids can be harmful. Wear gloves and eye protection to avoid contact with skin and eyes. Dispose of used fluids properly.

- Driveline Wind-Up: Be extremely cautious when testing or operating a vehicle with a locked or limited-slip differential on pavement. Driveline wind-up can create significant stress on the drivetrain and potentially cause component failure.

Components of particular concern are:

Driveshafts: High speed spinning components that can cause serious injury if they fail. Ensure they are properly balanced and maintained.

Springs: Can be under enormous tension. Use proper spring compressors.

Differentials: Contain heavy gears that can cause pinch points and crushing injuries. Be careful when disassembling and assembling them.

Understanding your 4WD system is the first step towards keeping it running smoothly and safely. Always consult your vehicle's service manual for specific instructions and recommendations. Remember, if you're not comfortable performing a particular repair, it's best to leave it to a qualified mechanic. We have a detailed diagram of a typical 4WD system available for download; it provides a visual aid to further your understanding and can be invaluable for troubleshooting. Feel free to download it and use it as a reference as you delve deeper into the intricacies of 4WD technology. Good luck, and happy wrenching!