How Important Is All Wheel Drive

Let's talk about All-Wheel Drive (AWD) – a system that's often misunderstood but crucial for traction and performance in many vehicles. This article will break down the technical aspects of AWD, helping you understand its components, operation, and importance, whether you're planning repairs, considering a modification, or simply want to expand your automotive knowledge.

Purpose: Understanding AWD for Maintenance and Modification

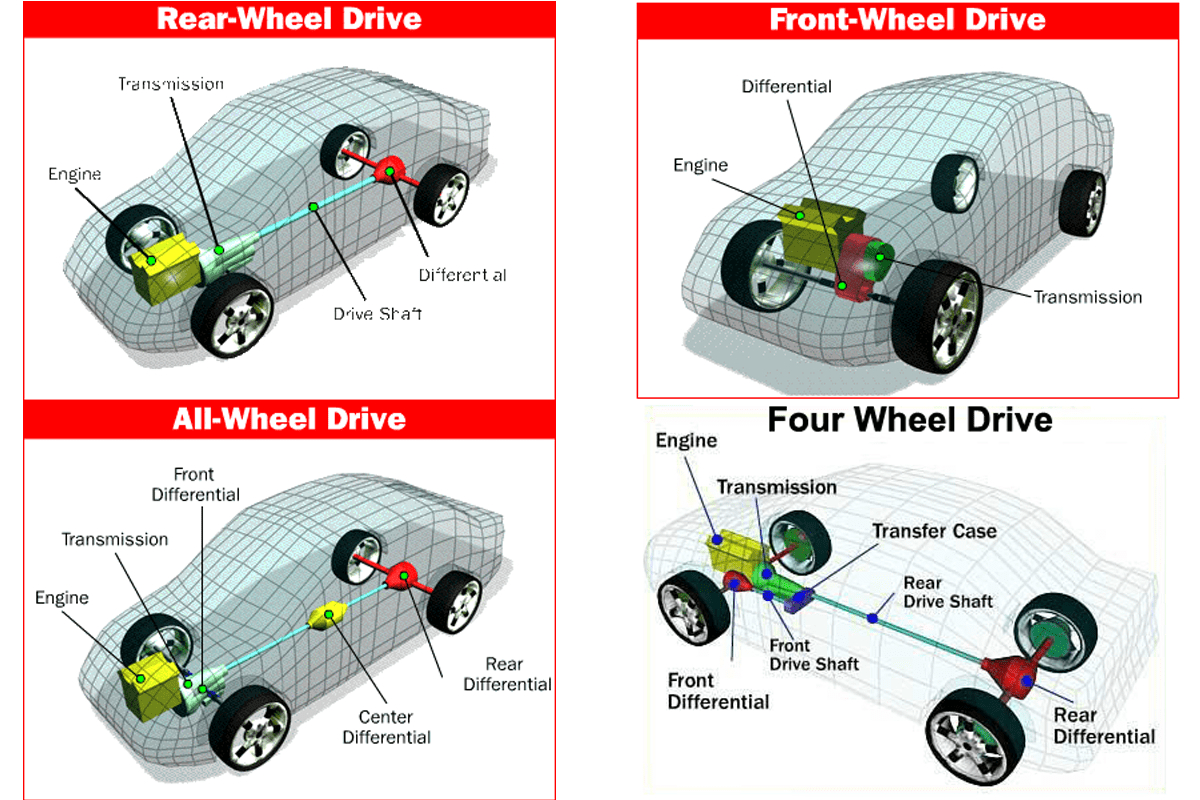

Understanding how AWD works is fundamental for diagnosing issues, performing maintenance, and even considering performance modifications. Many DIYers and modders jump into projects without fully grasping the intricacies of the system, leading to potential damage and wasted resources. This guide, alongside the detailed diagram we have available for download, will provide a solid foundation.

Key Specs and Main Parts of an AWD System

While specific implementations vary, most AWD systems share these core components:

- Engine: The source of power for the entire system.

- Transmission: Transfers power from the engine to the drivetrain. The type of transmission (manual, automatic, CVT) affects how power is distributed.

- Transfer Case: This is the heart of the AWD system. It takes power from the transmission and splits it between the front and rear axles. Some transfer cases offer selectable modes (e.g., 2WD, 4WD Auto, 4WD Lock).

- Front and Rear Differentials: Differentials allow the wheels on each axle to rotate at different speeds, which is essential for cornering. Open differentials are common, but limited-slip differentials (LSDs) or locking differentials provide enhanced traction.

- Axle Shafts (Half-Shafts): These transfer power from the differentials to the wheels.

- Driveshaft (Propeller Shaft): Connects the transfer case to the rear differential in most longitudinally-mounted engine AWD systems.

- Wheel Speed Sensors: These sensors monitor the speed of each wheel and are crucial for electronic AWD systems that use sensors to detect wheel slip.

- Control Unit (ECU/TCU): Manages the AWD system, often using inputs from wheel speed sensors, throttle position, and other vehicle sensors to determine the optimal torque split.

Important Specifications to Consider

- Torque Split: The percentage of engine torque sent to the front and rear axles (e.g., 50/50, 60/40, variable).

- Reaction Time: How quickly the system can react to wheel slip and transfer torque.

- Type of Coupling: The method used to transfer torque (e.g., viscous coupling, electronically controlled clutch pack, Torsen differential).

- Maximum Torque Transfer: The maximum amount of torque that can be transferred to one axle when the other is slipping.

AWD System Diagram Symbols Explained

Understanding the symbols used in an AWD system diagram is crucial for interpreting schematics and troubleshooting. Here's a breakdown of common symbols:

- Solid Lines: Typically represent mechanical connections, such as shafts and axles.

- Dashed Lines: Often indicate electrical connections or vacuum lines.

- Different Colors: Colors may be used to differentiate between different types of fluids (e.g., transmission fluid, differential fluid) or electrical signals. Refer to the diagram's legend for specific color meanings.

- Gear Symbols: Indicate gears within the transmission, transfer case, and differentials.

- Clutch Symbols: Represent clutches used to engage or disengage the AWD system or to vary the torque split.

- Sensor Symbols: Represent various sensors, such as wheel speed sensors, throttle position sensors, and yaw sensors.

- Actuator Symbols: Indicate devices that control the AWD system, such as solenoids and electric motors.

How All-Wheel Drive Works: A Detailed Explanation

The fundamental principle of AWD is to distribute power to all four wheels, thereby increasing traction. Different AWD systems achieve this in various ways. Here’s a closer look:

Full-Time AWD

In a full-time AWD system, all four wheels are constantly receiving power. A center differential or viscous coupling allows for speed differences between the front and rear axles, preventing driveline binding on paved surfaces. These systems generally offer superior traction in all conditions but may have slightly lower fuel economy compared to part-time systems.

Part-Time AWD (4WD)

Part-time AWD, often referred to as 4WD, is typically found in trucks and SUVs. It locks the front and rear axles together, providing maximum traction in off-road or slippery conditions. However, it should not be used on dry pavement because it can cause driveline binding and damage the transfer case. These systems require manual engagement, usually via a lever or buttons.

Automatic AWD (On-Demand AWD)

Automatic AWD, also known as on-demand AWD, is a reactive system that engages the rear wheels only when the front wheels lose traction. These systems typically use an electronically controlled clutch pack or viscous coupling to transfer torque to the rear axle. Wheel speed sensors detect wheel slip, and the control unit then activates the coupling to engage the rear wheels. This type of AWD offers a good balance between traction and fuel efficiency.

Torque Vectoring AWD

Torque vectoring AWD is a more advanced system that can actively distribute torque not only between the front and rear axles but also between the left and right wheels. This improves handling and stability, especially during cornering. These systems typically use electronically controlled clutches or differentials to precisely control torque distribution.

Real-World Use: Basic Troubleshooting Tips

Diagnosing AWD issues can be challenging, but here are a few common problems and troubleshooting tips:

- Driveline Binding: If you experience vibrations or jerking when turning on dry pavement, especially in a part-time 4WD system, you likely have driveline binding. Immediately disengage the 4WD system.

- AWD Light On: If the AWD warning light illuminates, it indicates a problem with the system. This could be a faulty sensor, a damaged actuator, or a problem with the control unit. Have the system scanned for trouble codes.

- Excessive Noise: Unusual noises, such as grinding or whining, from the transfer case or differentials could indicate wear or damage. Inspect the fluid levels and condition.

- Wheel Speed Sensor Issues: A faulty wheel speed sensor can disrupt the operation of the AWD system, leading to reduced traction or erratic behavior. Use a scan tool to check the sensor readings.

Safety: Highlighting Risky Components

Working on an AWD system can be hazardous if proper precautions are not taken. Here are some critical safety considerations:

- Driveline Components: Be extremely cautious when working near rotating driveline components, such as driveshafts and axles. Ensure the vehicle is properly supported and that the parking brake is engaged.

- High-Pressure Fluids: Some AWD systems use hydraulic actuators that operate at high pressure. Relieve the pressure before disconnecting any hydraulic lines.

- Electrical Components: Disconnect the battery before working on any electrical components of the AWD system. This will prevent accidental short circuits and potential damage.

- Torque Specifications: Always use a torque wrench and follow the manufacturer's torque specifications when tightening bolts and fasteners. Incorrect torque can lead to component failure.

- Fluid Handling: Properly dispose of used fluids, such as transmission fluid and differential fluid, according to local regulations.

Understanding All Wheel Drive is crucial for maintaining, repairing, and even upgrading your vehicle. By understanding its components and operation, you'll be better equipped to diagnose problems and keep your AWD system running smoothly. We have a detailed diagram of a common AWD system available for download – it's a valuable resource for further learning and practical application.