How Many Cylinders In A V6

Alright, let's talk about V6 engines. Specifically, how many cylinders you'll find nestled inside. The answer might seem obvious ("V6" kinda gives it away, right?), but understanding the layout and function is crucial whether you're tackling repairs, planning modifications, or just deepening your automotive knowledge. This isn't just about knowing the number; it's about understanding the geometry that makes a V6 tick.

Purpose: Why Understanding V6 Cylinder Configuration Matters

Why should you care about the cylinder count and arrangement? Here's the deal. This knowledge directly impacts your ability to:

- Diagnose Engine Problems: Knowing the firing order and cylinder locations is essential for troubleshooting misfires, compression issues, and other engine-related woes. If cylinder #3 is constantly misfiring, you need to know where cylinder #3 is!

- Perform Maintenance and Repairs: Spark plug replacement, injector cleaning, and even simple tasks like changing a coolant hose can be easier and safer if you have a clear picture of the engine layout.

- Plan Modifications: Want to upgrade your exhaust system or install performance headers? Understanding the V6 configuration will help you choose the right parts and avoid clearance issues.

- Improve Fuel Efficiency: Although cylinder count and arrangement have a indirect effect on fuel efficiency, understanding the engine layout will help you with diagnosing potential problems when fuel efficiency suddenly drop.

- Increase your overall Automotive Knowledge: The internal combustion engine is fascinating. Understanding different configurations like the V6 deepens your appreciation for automotive engineering.

Key Specs and Main Parts of a V6 Engine

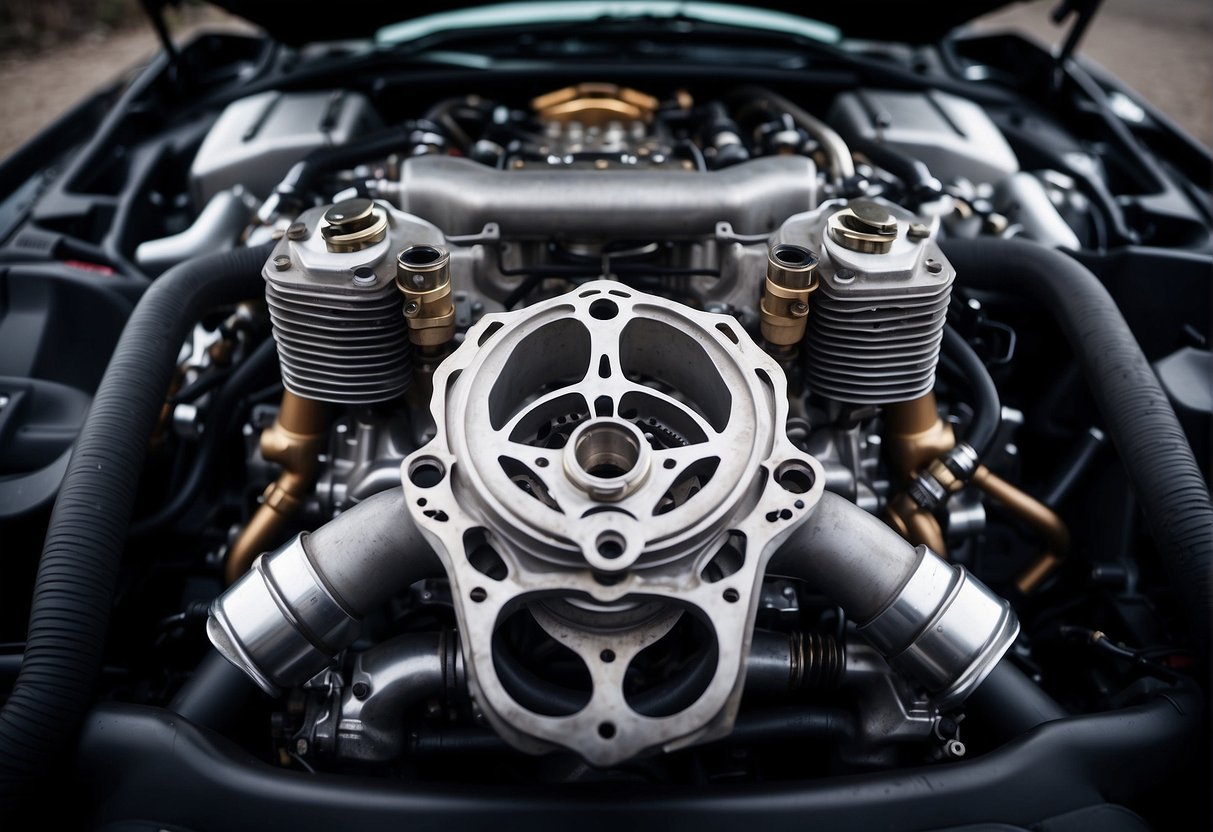

The defining characteristic of a V6 engine is, of course, the presence of six cylinders arranged in a "V" shape. Let's break down some key specs and parts:

- Cylinder Banks: A V6 engine has two cylinder banks, each typically containing three cylinders. These banks are angled relative to each other. The angle is crucial for balancing the engine.

- Bank Angle: The angle between the cylinder banks can vary. Common angles include 60 degrees, 90 degrees, and even narrower angles. A 60-degree V6 is generally considered to have the best inherent balance. A 90-degree V6 is often used when adapting a V8 engine design (where 90 degrees is common) to six cylinders, saving on manufacturing costs.

- Crankshaft: The crankshaft is the rotating shaft that converts the reciprocating motion of the pistons into rotational motion to drive the wheels. V6 crankshafts are complex, often employing counterweights to balance the engine and minimize vibrations.

- Connecting Rods: These connect the pistons to the crankshaft. In a V6, there's typically one connecting rod per piston.

- Pistons: The heart of the engine, these move up and down within the cylinders, compressing the air-fuel mixture and being pushed down by the expanding gases during combustion.

- Cylinder Head: The cylinder head sits atop each cylinder bank and contains the valves, camshaft(s), and combustion chambers.

- Valves: Intake valves allow the air-fuel mixture to enter the cylinders, while exhaust valves allow the burnt gases to exit.

- Camshaft(s): The camshaft controls the opening and closing of the valves. V6 engines can have one or two camshafts per cylinder bank (SOHC or DOHC).

- Firing Order: The sequence in which the cylinders fire is critical for smooth engine operation. The firing order is carefully designed to balance the engine and minimize vibrations. A typical V6 firing order might be 1-2-3-4-5-6.

Understanding V6 Diagram Symbols

When you look at a diagram of a V6 engine, you'll likely encounter various symbols. Here's a quick guide:

- Solid Lines: Usually represent physical connections, like hoses or wiring.

- Dashed Lines: Often indicate vacuum lines or signal pathways.

- Colors: Colors are used to differentiate systems. For example, fuel lines might be red, coolant lines blue, and vacuum lines green.

- Icons: Specific components have standardized icons. A rectangle with a jagged line might represent a resistor, a circle with a "T" inside could be a temperature sensor, and so on. Consult the diagram's legend for specifics.

How a V6 Engine Works

The V6 engine operates on the four-stroke combustion cycle: intake, compression, combustion (power), and exhaust. Let's quickly walk through them:

- Intake: The piston moves down, creating a vacuum that draws the air-fuel mixture into the cylinder through the open intake valve.

- Compression: The intake valve closes, and the piston moves up, compressing the air-fuel mixture.

- Combustion (Power): The spark plug ignites the compressed mixture, creating a rapid expansion of gases that pushes the piston down. This is where the engine generates power.

- Exhaust: The exhaust valve opens, and the piston moves up, pushing the burnt gases out of the cylinder.

This cycle repeats continuously in each cylinder, generating power that's transmitted to the crankshaft and ultimately to the wheels.

Real-World Use: Basic Troubleshooting Tips for V6 Engines

Here are a few basic troubleshooting tips related to V6 cylinder issues:

- Misfires: A misfire occurs when a cylinder doesn't fire properly. Common causes include faulty spark plugs, ignition coils, fuel injectors, or vacuum leaks. Use an OBD-II scanner to identify the misfiring cylinder.

- Compression Issues: Low compression in a cylinder can indicate worn piston rings, damaged valves, or a blown head gasket. A compression test will reveal any compression problems.

- Rough Idle: A rough idle can be caused by a variety of issues, including vacuum leaks, dirty throttle body, or problems with the idle air control (IAC) valve.

Important: Always consult a repair manual or a qualified mechanic for more complex diagnostic procedures.

Safety: Highlighting Risky Components

Working on a V6 engine involves potential hazards. Here are some key safety considerations:

- High Voltage: The ignition system operates at high voltage. Always disconnect the battery before working on any electrical components related to the ignition system.

- Fuel System: Gasoline is flammable. Work in a well-ventilated area and avoid sparks or open flames when working on the fuel system. Relieve fuel pressure before disconnecting any fuel lines.

- Hot Surfaces: The engine can get extremely hot. Allow the engine to cool completely before working on it, especially the exhaust system.

- Moving Parts: Be aware of moving parts like the crankshaft, camshafts, and belts. Keep your hands and tools clear of these components when the engine is running or being cranked.

- Proper Tools: Always use the correct tools for the job. Using the wrong tool can damage components or cause injury.

- Eye Protection: Always wear safety glasses to protect your eyes from debris.

Disassembly and work on the internal engine components should only be done with the proper training and experience. Working on engines is inherently risky and potentially dangerous if not done correctly.

So, to definitively answer the initial question, a V6 engine has six cylinders. But hopefully, you now have a much more comprehensive understanding of what that means in terms of layout, function, and troubleshooting. Happy wrenching!