How Many Cylinders In A V8

Alright, let's dive into the heart of a V8 engine. You're here because you want to understand this iconic powerplant, whether it's for repairs, modifications, or just plain old knowledge. This article will give you a solid understanding of the V8's configuration, specifically focusing on the cylinder count and arrangement. We're going to skip the marketing fluff and get straight to the nuts and bolts, assuming you've got some experience turning wrenches already.

Purpose: Why Understanding V8 Cylinder Arrangement Matters

Why bother understanding how many cylinders are in a V8 and how they're arranged? Simple: It's fundamental to everything else. Knowing the cylinder layout is critical for:

- Diagnosis: Pinpointing misfires, identifying faulty cylinders, and tracing vacuum leaks all depend on knowing the cylinder numbering and firing order.

- Repairs: Replacing spark plugs, ignition coils, injectors, or even more extensive work like head gaskets or piston rings requires a solid understanding of the cylinder locations.

- Modifications: Upgrading camshafts, installing headers, or tuning the engine's performance requires precise knowledge of the engine's geometry and cylinder-specific parameters.

- General Maintenance: Even routine maintenance like oil changes and filter replacements benefit from a deeper understanding of the engine's overall architecture.

- Engine Swaps: If you're dreaming of swapping in a bigger or different engine, understanding the V8's configuration is crucial for ensuring proper fitment and compatibility.

In short, understanding the V8 cylinder arrangement is a cornerstone of working on these engines. It's the foundation upon which all other knowledge is built.

Key Specs and Main Parts

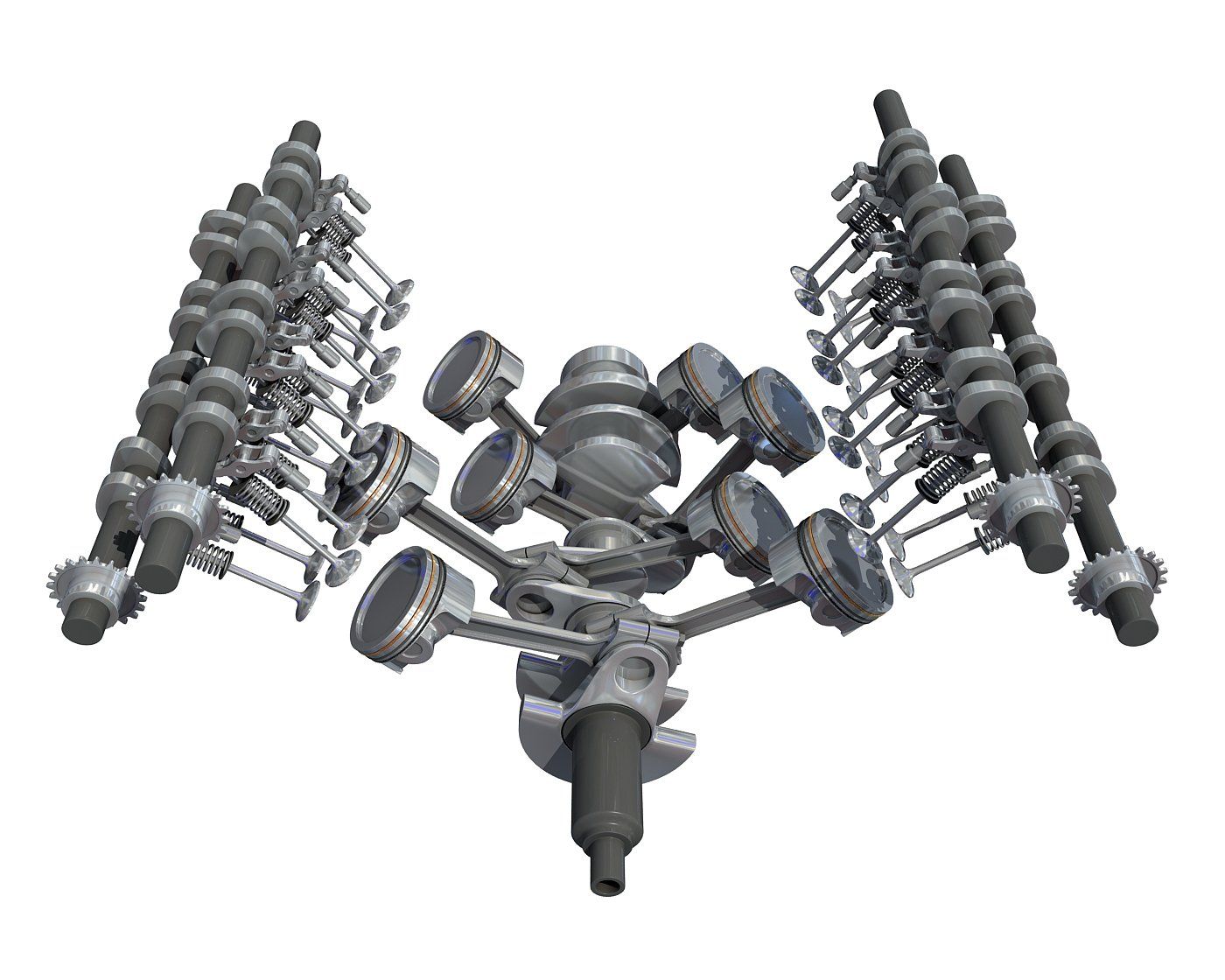

The "V8" designation tells you the two most important things about this engine: it has eight cylinders, and they are arranged in a "V" configuration. Here's a breakdown of the key specs and parts:

- Cylinders: Eight in total. These are the chambers where combustion happens.

- Cylinder Banks: Two banks of four cylinders each. These banks are angled relative to each other. The angle varies, but 90 degrees is common.

- Crankshaft: The rotating shaft to which the pistons are connected via connecting rods. The crankshaft converts the linear motion of the pistons into rotational motion.

- Connecting Rods (Rods): These connect the pistons to the crankshaft.

- Pistons: Move up and down within the cylinders, compressing the air-fuel mixture and being driven down by the combustion force.

- Cylinder Heads: Cover the cylinders and house the valves (intake and exhaust) and spark plugs.

- Valves: Control the flow of air and fuel into the cylinders (intake valves) and the exhaust gases out of the cylinders (exhaust valves).

- Camshaft(s): Rotate and operate the valves through pushrods or directly (in overhead cam designs). V8 engines can have a single camshaft (OHV) or multiple camshafts (DOHC).

- Firing Order: The sequence in which the cylinders fire. This is crucial for balanced engine operation and smooth power delivery. Common firing orders for V8s include 1-8-4-3-6-5-7-2 and 1-5-4-8-6-3-7-2.

The "V" angle between the cylinder banks is critical. A 90-degree V8 is inherently balanced, reducing vibrations. However, other angles are used, often requiring more complex crankshaft designs and counterweights to mitigate vibrations.

How It Works

The V8 engine operates on the four-stroke principle: intake, compression, combustion (or power), and exhaust. Let's break it down:

- Intake: The piston moves down, creating a vacuum in the cylinder. The intake valve opens, allowing the air-fuel mixture to be drawn into the cylinder.

- Compression: The piston moves up, compressing the air-fuel mixture. Both intake and exhaust valves are closed.

- Combustion (Power): The spark plug ignites the compressed air-fuel mixture, creating a rapid expansion of gases. This force pushes the piston down.

- Exhaust: The piston moves up, pushing the exhaust gases out of the cylinder through the open exhaust valve.

This cycle repeats in each of the eight cylinders, but each cylinder is at a different stage of the cycle at any given time. This coordinated effort, dictated by the firing order, provides a continuous flow of power to the crankshaft.

Real-World Use: Basic Troubleshooting Tips

Here's how understanding the V8's cylinder arrangement can help you troubleshoot common problems:

- Misfires: A misfire occurs when a cylinder fails to fire properly. Using a scan tool or a basic timing light, you can often identify which cylinder is misfiring. Knowing the cylinder numbering allows you to focus your diagnosis on that specific cylinder's components (spark plug, coil, injector).

- Vacuum Leaks: Vacuum leaks can cause rough idling and poor performance. Knowing the location of the intake manifold runners and vacuum lines relative to the cylinders can help you pinpoint the source of the leak.

- Exhaust Manifold Leaks: Exhaust manifold leaks can be noisy and reduce engine efficiency. Identifying the leaking cylinder is essential for replacing the correct gasket.

Example: Let's say you have a code indicating a misfire on cylinder #4. Knowing the cylinder numbering scheme (which varies slightly between manufacturers, so always consult your vehicle's specific documentation) allows you to quickly locate cylinder #4, inspect its spark plug, coil, and injector, and test for compression.

Safety: Highlight Risky Components

Working on a V8 engine involves inherent risks. Here are some critical safety points:

- High Voltage: The ignition system carries extremely high voltage. Always disconnect the battery before working on any part of the ignition system (spark plugs, coils, wires). Even with the battery disconnected, residual voltage can remain in capacitors.

- Fuel System: The fuel system is under pressure. Relieve the fuel pressure before disconnecting any fuel lines or injectors. Fuel is flammable and can cause serious burns.

- Hot Surfaces: Exhaust manifolds and other engine components get extremely hot. Allow the engine to cool completely before working on it.

- Moving Parts: Never put your hands near moving parts, especially the crankshaft, belts, and pulleys, while the engine is running.

- Lifting Heavy Components: Use proper lifting equipment (engine hoist, jacks, stands) when lifting heavy engine components like the engine block or cylinder heads. Ensure the components are securely supported before working on them.

- Eye Protection: Always wear safety glasses when working on engines to protect your eyes from debris.

- Chemicals: Use appropriate gloves and ventilation when working with solvents, cleaners, and other chemicals.

Always consult your vehicle's repair manual for specific safety precautions and procedures.

This detailed explanation provides a solid foundation for understanding the intricacies of a V8 engine and its cylinder arrangement. Remember to consult your vehicle's specific service manual for detailed procedures and specifications relevant to your particular engine. The best way to learn is by doing, but always prioritize safety and double-check your work.