How Many Cylinders Is A V8

Alright, let's dive into the heart of a V8 engine and definitively answer the question: How many cylinders does a V8 have? Obviously, the answer is eight. But understanding the architecture of this engine is crucial for a variety of reasons, whether you're tackling repairs, planning modifications, or simply deepening your automotive knowledge. This article will break down the key specs, internal workings, and even offer some troubleshooting tips related to the V8's cylinder configuration.

Purpose of Understanding V8 Configuration

Why bother learning about the V8 layout? Several reasons. First, it aids in diagnostics. Knowing the cylinder arrangement helps you pinpoint which cylinder might be misfiring or experiencing issues. Second, for those doing engine work – replacing head gaskets, timing components, or even performing a rebuild – a clear understanding of the cylinder bank layout is essential for proper assembly and torqueing procedures. Finally, for aspiring engine tuners and performance enthusiasts, knowledge of the cylinder bank configuration is paramount for optimizing fuel delivery, ignition timing, and exhaust flow.

Key Specs and Main Parts of a V8 Engine

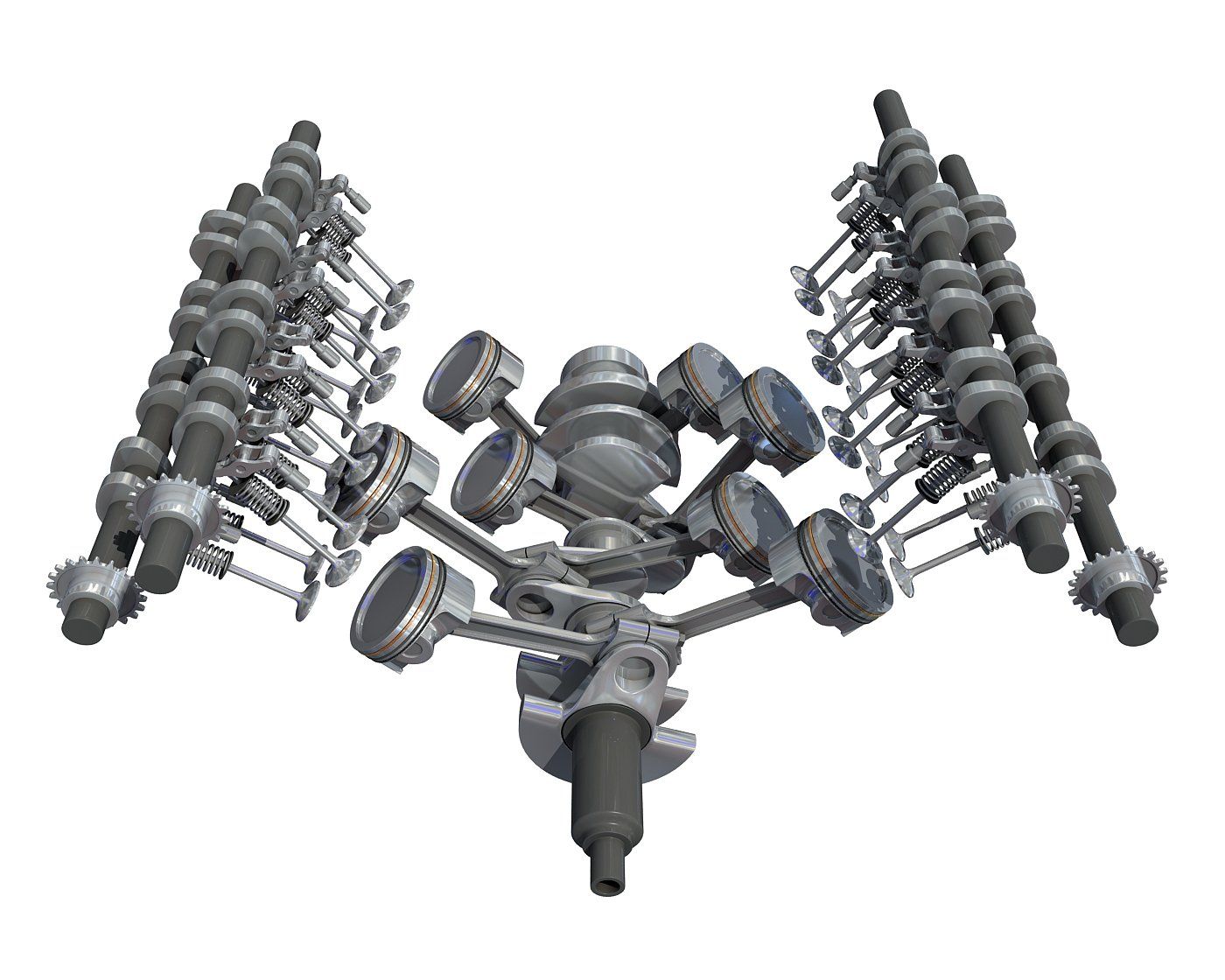

The defining characteristic of a V8 engine is its eight cylinders arranged in two banks of four, forming a "V" shape. This configuration offers a good balance of power and relatively compact size, making it a popular choice for performance cars, trucks, and SUVs. Here's a breakdown of the key specs and main components:

- Cylinder Banks: Two banks of four cylinders each, typically angled at 90 degrees, although other angles exist (e.g., some Ford engines use 60-degree V8s). The angle influences the engine's width, height, and balance characteristics.

- Firing Order: The sequence in which the cylinders fire. This is critical for smooth engine operation and is often dictated by the camshaft profile and crankshaft design. Common firing orders include 1-8-4-3-6-5-7-2 and 1-5-4-8-6-3-7-2.

- Crankshaft: The rotating shaft that converts the linear motion of the pistons into rotational motion. V8 crankshafts are usually a cross-plane design to manage vibrations, though flat-plane crankshafts are found in some high-performance applications.

- Camshaft(s): Controls the opening and closing of the intake and exhaust valves. A V8 engine can have one or two camshafts per cylinder bank (single overhead cam - SOHC or dual overhead cam - DOHC).

- Cylinder Heads: The component that sits atop each cylinder bank, housing the valves, spark plugs, and combustion chamber.

- Intake Manifold: Distributes air to the cylinders. Designs vary significantly, impacting engine performance at different RPM ranges.

- Exhaust Manifold/Headers: Collects exhaust gases from the cylinders and directs them to the exhaust system.

- Block: The main structural component of the engine, containing the cylinders and supporting the crankshaft.

- Pistons: Move up and down within the cylinders, driven by the combustion process.

- Connecting Rods: Connect the pistons to the crankshaft.

Understanding V8 Engine Diagrams and Symbols

V8 engine diagrams, whether in repair manuals or online resources, use standardized symbols to represent various components. Here’s a general guide:

- Solid Lines: Typically represent rigid components like the engine block, cylinder heads, and intake manifold.

- Dashed Lines: Often indicate fluid or vacuum lines.

- Arrows: Show the direction of fluid flow (oil, coolant, fuel) or movement of mechanical parts (pistons, valves).

- Color Coding: Can be used to differentiate between different systems. For example, blue might represent coolant lines, red for oil lines, and yellow for fuel lines. Always check the diagram's legend to understand the specific color scheme.

- Specific Component Symbols: Each component has its own unique symbol. These symbols are usually standardized, but it's always best to refer to the diagram's legend for clarification. Common symbols include those for spark plugs, valves, sensors (oxygen sensors, temperature sensors), and actuators.

How a V8 Engine Works

The V8 engine operates on the four-stroke principle: intake, compression, combustion (power), and exhaust. Let's break it down:

- Intake Stroke: The piston moves down the cylinder, creating a vacuum that draws air and fuel (or just air in direct injection systems) into the cylinder through the open intake valve.

- Compression Stroke: The intake valve closes, and the piston moves up the cylinder, compressing the air-fuel mixture. This increases the mixture's temperature and pressure, preparing it for combustion.

- Combustion (Power) Stroke: The spark plug ignites the compressed air-fuel mixture, creating a rapid expansion of gases that forces the piston down the cylinder. This is the power stroke that drives the crankshaft.

- Exhaust Stroke: The exhaust valve opens, and the piston moves up the cylinder, pushing the burnt exhaust gases out of the cylinder and into the exhaust manifold.

This four-stroke cycle repeats continuously in each cylinder, but with precise timing dictated by the camshaft and firing order. The firing order ensures that the power strokes are evenly distributed, resulting in smooth and efficient engine operation. The V arrangement of the cylinders allows for a relatively short crankshaft, which contributes to engine rigidity and reduces vibrations compared to an inline engine with the same number of cylinders.

Real-World Use and Basic Troubleshooting

Understanding the V8 cylinder configuration is invaluable for troubleshooting engine problems. Here are a few examples:

- Misfires: A misfire occurs when one or more cylinders fail to fire correctly. Using a diagnostic scan tool (OBDII scanner), you can identify the specific cylinder that's misfiring. Knowing the cylinder bank layout allows you to quickly locate the corresponding spark plug, ignition coil, or fuel injector for inspection.

- Head Gasket Leaks: A blown head gasket can cause coolant to leak into the cylinder, resulting in white smoke from the exhaust. Understanding which cylinder bank is affected can help you narrow down the location of the leak and plan the repair accordingly.

- Valve Train Noise: Ticking or tapping noises from the valve train can indicate worn lifters, rocker arms, or valve springs. Identifying the affected cylinder bank will help you pinpoint the source of the noise.

Safety Precautions

Working on a V8 engine involves certain risks. Always disconnect the battery before working on the electrical system. Fuel systems are under pressure, so relieve the pressure before disconnecting any fuel lines. Exhaust systems can remain hot for a long time after the engine is shut off, so allow them to cool completely before handling them. Be especially careful when working around the rotating components, such as the crankshaft and camshaft, as these can cause serious injury if they are accidentally engaged. Wear appropriate safety gear, including eye protection and gloves, when handling chemicals or sharp objects.

Additionally, remember that improper installation of components, especially those related to timing, can lead to catastrophic engine damage. Always follow the manufacturer's instructions carefully and double-check your work.

We have a detailed V8 engine diagram available for download that shows all the components mentioned above. It includes detailed labeling and color coding to help you understand the engine layout. This diagram will be an invaluable resource for your future projects.