How Many Liters In A V8 Engine

Understanding the displacement of a V8 engine – that is, knowing how many liters it is – is fundamental to diagnosing problems, planning modifications, and truly grasping the heart of your vehicle. This information isn't just a random number; it directly correlates to power output, fuel efficiency, and overall engine characteristics. Whether you're planning an engine swap, troubleshooting a misfire, or simply want to impress your friends with your automotive knowledge, understanding engine displacement is crucial.

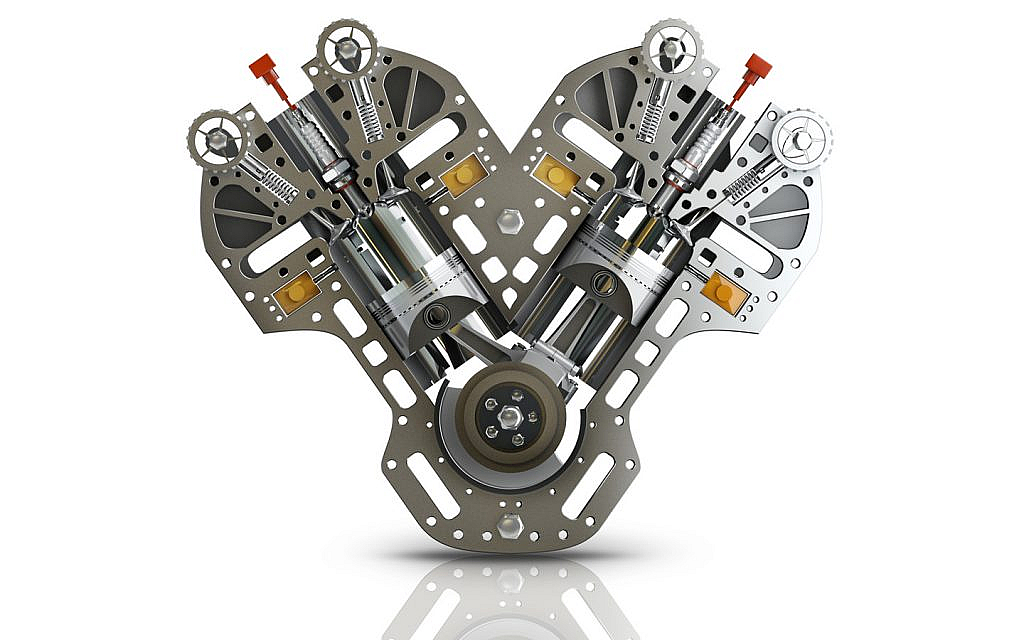

Key Specs and Main Parts Defining Displacement

The displacement of an engine is the total volume displaced by all the pistons during one complete stroke. In the context of a V8 engine, we're dealing with eight cylinders, each contributing to the overall displacement. The following specifications are critical in calculating (or understanding an already calculated) displacement:

- Bore: The diameter of each cylinder. Imagine a perfectly round hole; the bore is the width of that hole. It's typically measured in millimeters (mm) or inches (in).

- Stroke: The distance the piston travels from its highest point (Top Dead Center, or TDC) to its lowest point (Bottom Dead Center, or BDC). This is also typically measured in millimeters (mm) or inches (in).

- Number of Cylinders: In our case, a V8 engine has eight cylinders.

The main parts directly involved in the displacement calculation and operation are:

- Cylinder Block: The foundational structure of the engine, containing the cylinders.

- Pistons: The moving components within the cylinders that compress the air-fuel mixture.

- Connecting Rods: Connect the pistons to the crankshaft.

- Crankshaft: Converts the linear motion of the pistons into rotational motion, which ultimately drives the wheels.

The formula for calculating the displacement of one cylinder is: π * (Bore/2)² * Stroke. To get the total engine displacement, you multiply this value by the number of cylinders. Remember to use consistent units (e.g., millimeters for both bore and stroke) and then convert the result to liters (L) or cubic inches (ci) as needed.

Example Calculation

Let's say we have a V8 engine with a bore of 101.6 mm (4 inches) and a stroke of 88.39 mm (3.48 inches). First, calculate the displacement of one cylinder:

π * (101.6 mm / 2)² * 88.39 mm ≈ 717,734 mm³

Now, multiply by the number of cylinders (8):

717,734 mm³ * 8 ≈ 5,741,872 mm³

Finally, convert cubic millimeters to liters (1 L = 1,000,000 mm³):

5,741,872 mm³ / 1,000,000 mm³/L ≈ 5.74 L

Therefore, this engine would be approximately a 5.7L V8.

How It Works: The Displacement Cycle

The displacement value arises from the cyclical motion of the pistons within the cylinders. Each cylinder undergoes a four-stroke cycle:

- Intake Stroke: The piston moves down, creating a vacuum in the cylinder, and the intake valve opens, allowing air (or an air-fuel mixture) to be drawn in.

- Compression Stroke: The intake valve closes, and the piston moves up, compressing the air-fuel mixture. This compression increases the temperature and pressure, making it easier to ignite.

- Combustion Stroke (Power Stroke): The spark plug ignites the compressed air-fuel mixture, creating a rapid expansion of gases that pushes the piston down with considerable force. This is where the engine generates power.

- Exhaust Stroke: The exhaust valve opens, and the piston moves up, pushing the exhaust gases out of the cylinder.

The volume displaced by the piston during the intake, compression, combustion, and exhaust strokes determines the displacement of that individual cylinder. Summing the displacement of all eight cylinders gives us the total engine displacement.

Real-World Use and Basic Troubleshooting

Understanding engine displacement is crucial for several reasons. Firstly, it helps in diagnosing performance issues. For example, a loss of power in an engine might indicate a problem affecting the displacement, such as worn piston rings (leading to compression loss) or damaged cylinder walls.

Troubleshooting Tips:

- Compression Test: A compression test measures the pressure inside each cylinder. Low compression in one or more cylinders can suggest problems with piston rings, valves, or cylinder head gaskets, all impacting displacement effectiveness.

- Leak-Down Test: A leak-down test identifies the source of compression loss by pressurizing the cylinder and listening for air leaks in various areas (e.g., intake, exhaust, crankcase).

- Visual Inspection: While requiring disassembly, a visual inspection of the cylinders, pistons, and piston rings can reveal signs of wear or damage.

Secondly, displacement is a critical factor when selecting aftermarket parts, especially those related to performance upgrades. For example, choosing the correct size of fuel injectors, camshaft, or turbocharger requires knowledge of the engine's displacement.

Safety Considerations

Working on engines involves inherent risks. Always disconnect the negative battery terminal before starting any work to prevent electrical shock or accidental starting. Gasoline is highly flammable; work in a well-ventilated area and avoid sparks or open flames. The fuel system, including fuel injectors and fuel lines, is under pressure, so relieve the pressure before disconnecting any fuel components. Also, never work under a vehicle supported only by a jack; use jack stands. Finally, always wear safety glasses to protect your eyes from debris.

Risk Components:

- Fuel System: Flammable and pressurized.

- Electrical System: Potential for electric shock.

- Moving Parts: Risk of injury if the engine accidentally starts.

- Hot Surfaces: Exhaust manifold and other components can be extremely hot.

In summary, the liters in a V8 engine represents the sum total of displacement of eight cylinders and provides insights into engine performance. Remember to always refer to your vehicle's service manual for specific information about your engine. For more detailed information on the V8 engine and associated components, we have a detailed diagram available for download. This diagram provides a visual representation of the key parts and their relationships, aiding in understanding the workings of the engine.