How Many Liters Is A V8 Engine

Okay, let's talk about V8 engines and how we measure their size in liters. It's a fundamental concept in the automotive world, and understanding it is crucial whether you're planning engine modifications, diagnosing problems, or just want to have a deeper appreciation for what's under the hood. We'll break down the technical jargon and make it easy to grasp.

Why Understanding Engine Displacement Matters

Knowing the displacement of your V8 engine isn't just about bragging rights. It's vital for:

- Performance Upgrades: Choosing the right size turbocharger, supercharger, or camshaft depends directly on the engine's displacement.

- Troubleshooting: Many diagnostic procedures and performance benchmarks are displacement-specific. A misfire on a 5.7L V8 has different potential causes than one on a 4.6L.

- Parts Selection: Ordering the correct pistons, rings, or cylinder heads requires knowing the exact engine displacement.

- General Understanding: It gives you a fundamental insight into the engine's potential power output and fuel efficiency.

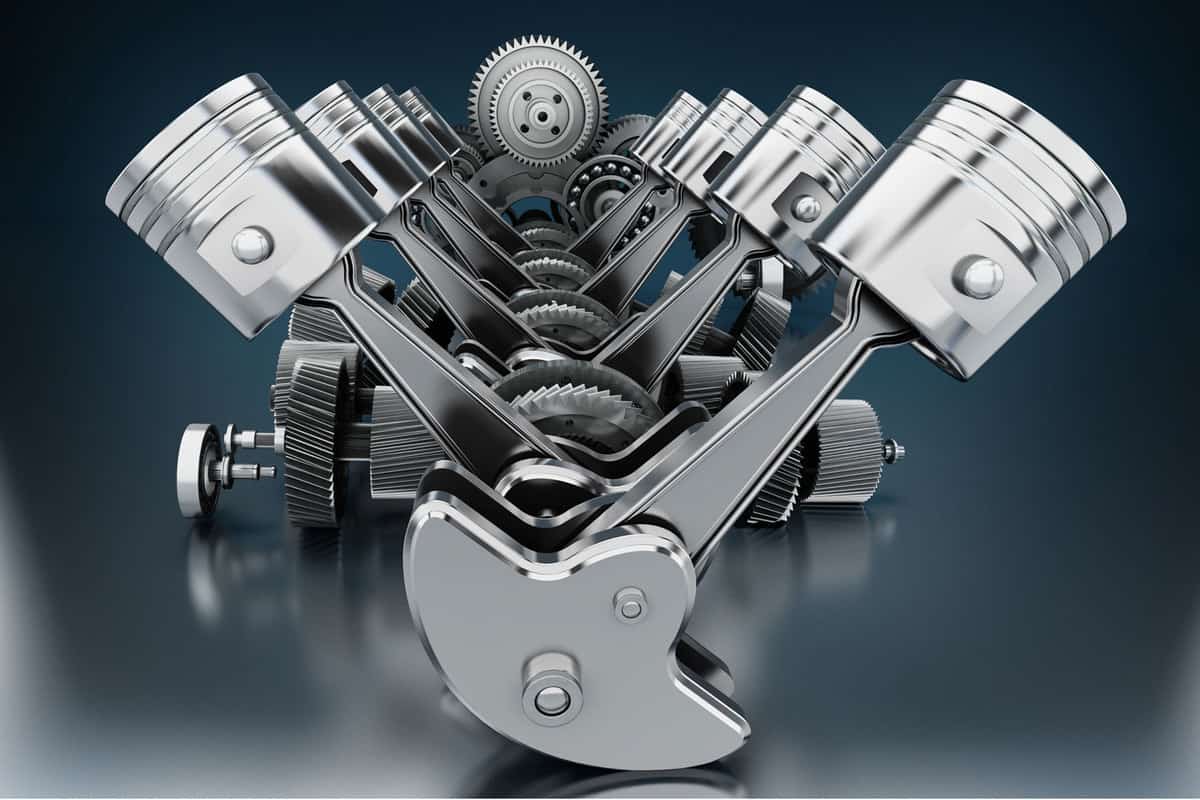

Key Specs and Main Parts of a V8 Engine

A V8 engine, as the name suggests, has 8 cylinders arranged in a "V" configuration. This layout helps with balance and can be more compact than an inline-8. Here are some key specs and parts we need to understand:

- Cylinder: The core of the engine where combustion happens. It's a precisely machined bore within the engine block.

- Piston: A cylindrical component that moves up and down within the cylinder, driven by the force of combustion.

- Connecting Rod (Con-Rod): Connects the piston to the crankshaft. It transmits the piston's linear motion into rotational motion.

- Crankshaft: The rotating shaft that converts the reciprocating motion of the pistons into rotational motion that drives the wheels.

- Bore: The diameter of the cylinder. It's a critical dimension for calculating displacement.

- Stroke: The distance the piston travels from its highest point (Top Dead Center, or TDC) to its lowest point (Bottom Dead Center, or BDC).

- Displacement (Engine Displacement): The total volume swept by all the pistons inside the cylinders during one complete stroke. It's usually measured in liters or cubic inches.

How Engine Displacement (Liters) is Calculated

The displacement of a single cylinder is calculated using the following formula:

Cylinder Displacement = π * (Bore / 2)² * Stroke

Where:

- π (Pi) is approximately 3.14159

- Bore is the diameter of the cylinder (measured in millimeters, inches, etc.)

- Stroke is the distance the piston travels (measured in millimeters, inches, etc.)

To get the total engine displacement, you multiply the cylinder displacement by the number of cylinders. For a V8:

Engine Displacement = Cylinder Displacement * 8

To convert cubic inches to liters, you divide the cubic inch displacement by 61.024. To convert liters to cubic inches, you multiply the liters by 61.024.

Example: Let's say a V8 engine has a bore of 4 inches and a stroke of 3.4 inches. First, calculate the area of the bore: π * (4/2)² = 3.14159 * 4 = 12.566 square inches. Then multiply by the stroke: 12.566 * 3.4 = 42.724 cubic inches per cylinder. Finally, multiply by the number of cylinders: 42.724 * 8 = 341.79 cubic inches. To convert to liters: 341.79 / 61.024 = 5.6 Liters (approximately). That's a 5.7L V8 (rounded up).

How a V8 Engine Works (Brief Overview)

The V8 engine operates on a four-stroke cycle:

- Intake: The piston moves down, creating a vacuum that draws air and fuel mixture into the cylinder.

- Compression: The piston moves up, compressing the air-fuel mixture.

- Combustion (Power): The spark plug ignites the compressed mixture, creating a powerful explosion that forces the piston down.

- Exhaust: The piston moves up, pushing the burnt gases out of the cylinder through the exhaust valve.

This cycle repeats continuously in each cylinder, providing the power to turn the crankshaft and ultimately, the wheels.

Real-World Use: Basic Troubleshooting Tips Related to Displacement

Understanding engine displacement can help with troubleshooting:

- Lack of Power: If an engine feels significantly weaker than it should for its displacement, suspect issues like low compression, timing problems, or fuel delivery issues. A compression test can reveal problems like worn piston rings or leaky valves.

- Poor Fuel Economy: A sudden drop in fuel economy for a given engine displacement could indicate problems like a faulty oxygen sensor, leaky fuel injectors, or excessive engine wear.

- Misfires: Misfires, especially if isolated to one or two cylinders, can be related to individual cylinder issues, like a bad spark plug, faulty ignition coil, or a problem with the fuel injector. Knowing the displacement helps you understand the expected behavior of each cylinder.

Pro Tip: When diagnosing engine problems, always start with the basics. Check for fault codes using an OBD-II scanner. A code related to a cylinder misfire (e.g., P0301 for Cylinder 1) is a good starting point.

Safety Considerations

Working on engines involves inherent risks. Always prioritize safety:

- High Voltage: The ignition system contains high-voltage components. Disconnect the battery before working on the ignition system to avoid electric shock.

- Flammable Fluids: Fuel and oil are flammable. Work in a well-ventilated area and keep open flames away.

- Hot Surfaces: The engine can get extremely hot. Allow the engine to cool down completely before working on it.

- Moving Parts: Keep your hands and tools clear of moving parts when the engine is running.

- Use Proper Tools: Using the correct tools for the job is essential for safety and preventing damage to the engine.

- Lifting Heavy Components: When lifting heavy engine components, like cylinder heads or the engine block itself, use appropriate lifting equipment (engine hoist, cherry picker) and follow safety guidelines. Never attempt to lift these components without proper equipment and training.

- Fuel Injection Systems: Fuel injection systems can maintain high fuel pressure even after the engine is turned off. Before disconnecting fuel lines, relieve the fuel pressure using the appropriate procedure (usually involving disconnecting the fuel pump relay and running the engine until it stalls).

Warning: Never work under a vehicle supported only by a jack. Use jack stands to provide secure support.

Visualizing the V8: Where to Find Engine Diagrams

A detailed diagram of a V8 engine can be incredibly helpful for understanding its construction and function. These diagrams typically show the various components, their relationships, and how they work together. Look for detailed illustrations of your specific engine model. A good place to look are repair manuals online or even engine component manufacturer websites.

I have a detailed diagram of a generic V8 engine layout available that covers key components. You can download it from [Link to Diagram - Placeholder]. This diagram provides a visual overview of the engine's internal workings, including the cylinders, pistons, connecting rods, crankshaft, and valve train. We also have a variety of other helpful resources available.

By understanding the principles of engine displacement and the basic operation of a V8 engine, you'll be better equipped to tackle maintenance, modifications, and troubleshooting tasks. Remember to always prioritize safety and consult with experienced professionals when necessary. Good luck!