How Many Sides Does A Cylinder

Alright, let's tackle a question that might seem simple on the surface, but actually dives into the nuances of geometry and how we represent 3D objects in a 2D world: How many sides does a cylinder have? The answer, as with many things in automotive mechanics, isn't quite as straightforward as you might think. The answer depends heavily on how you define a "side," and in the context of engine cylinders, this distinction becomes particularly important for understanding machining, repairs, and design.

Why This Matters: Beyond Basic Geometry

You might be thinking, "Why do I need to know this for my car?" Well, understanding the fundamental geometry of engine components is critical for several reasons. Firstly, it directly impacts repair work. Knowing the surface characteristics of a cylinder – whether it’s idealized or real-world – is crucial for honing, boring, and sleeving operations. Secondly, when diagnosing engine problems like blow-by or compression loss, you’re essentially dealing with how well these "sides" are sealing. Furthermore, if you're getting into engine modification or performance tuning, knowledge of cylinder geometry becomes invaluable for calculating displacement, compression ratios, and optimizing combustion chamber design.

Key Specs and Main Parts

Let's define what we're dealing with. A cylinder in this context usually refers to the cylindrical void within an engine block where the piston travels. The critical features influencing the "sides" of this cylinder are:

- Cylinder Walls: This is the main working surface. Ideally, it should be perfectly cylindrical and smooth.

- Top Deck: The surface where the cylinder head bolts on. This contributes to a face of the cylinder.

- Bottom Deck: This is the part of the cylinder that connects to the crankcase. The geometry here is important to structural integrity.

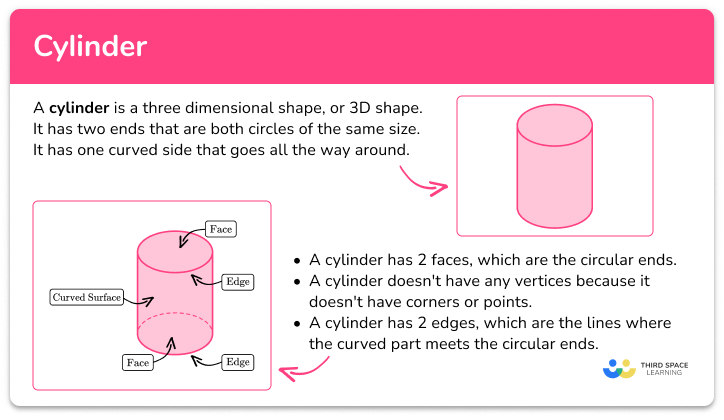

Now, the tricky part. Mathematically, a perfect cylinder consists of:

- One Curved Surface: This is the smooth, continuous surface forming the cylinder wall. Think of it as a rolled-up rectangle.

- Two Circular Faces: These are the flat, circular ends of the cylinder.

So, technically, a perfect cylinder has three surfaces – one curved and two circular. However, in the automotive world, we usually only care about the cylinder walls itself, which is one surface.

Interpreting Technical Drawings: Lines and Symbols

When dealing with engine diagrams or repair manuals, you'll encounter various symbols representing the cylinder. Understanding these is key to interpreting the drawing effectively.

- Solid Lines: These typically represent visible edges or surfaces. In a cylinder diagram, solid lines would outline the cylinder walls and the top and bottom decks.

- Dashed Lines: Dashed lines indicate hidden edges or features that are not directly visible in the drawing's viewpoint. These might show the cylinder bore behind other components.

- Center Lines: Represented by a long-short-long pattern, center lines mark the axis of symmetry of the cylinder. These are crucial for aligning tools and components during assembly.

- Hatching: Hatching (or section lining) indicates a cutaway view of the cylinder, revealing its internal structure and material.

- Tolerance Symbols: Geometric dimensioning and tolerancing (GD&T) symbols define acceptable variations in the cylinder's size, shape, and position. These are *critical* when machining or inspecting cylinders. For example, a symbol for cylindricity specifies how closely the cylinder conforms to a perfect cylinder.

Colors are often used in diagrams to highlight specific features or materials. For instance, different shades of grey might represent different materials used in the cylinder block. Always refer to the diagram's legend for a clear understanding of what each color signifies.

How It Works: The Cylinder's Role

The cylinder's primary function is to provide a sealed chamber where combustion can occur and drive the piston. The *integrity* of the cylinder walls is paramount for efficient engine operation. If the cylinder walls are damaged or worn, combustion gases can leak past the piston rings (a phenomenon known as blow-by), leading to reduced power, increased oil consumption, and potentially engine damage. The cylinder itself provides support for the piston as it moves up and down.

The geometry impacts everything. A slightly out-of-round cylinder (meaning the diameter isn't perfectly constant) will lead to uneven wear on the piston rings and increased friction. Similarly, surface imperfections on the cylinder wall will prevent the rings from sealing properly. Therefore, maintaining the correct cylinder geometry is crucial during engine rebuilding or repair.

Real-World Use: Troubleshooting Common Cylinder Issues

Here are a few scenarios where understanding cylinder geometry is invaluable:

- Compression Test: A low compression reading in one or more cylinders often indicates a problem with the cylinder sealing. This could be due to worn piston rings, damaged cylinder walls (scoring), or valve issues.

- Leak-Down Test: This test helps pinpoint the source of a compression leak. Air escaping from the crankcase usually indicates a problem with the piston rings or cylinder walls.

- Cylinder Bore Gauging: Using a bore gauge allows you to measure the cylinder's diameter at various points. This helps detect wear, taper (diameter decreasing towards the top of the cylinder), and out-of-roundness.

- Honing: This process involves using a honing tool to create a specific crosshatch pattern on the cylinder walls. This pattern provides a surface for the piston rings to seat properly and retain oil.

- Cylinder Sleeving: When a cylinder is severely damaged beyond repair, a cylinder sleeve can be installed. This involves boring out the original cylinder and pressing in a new sleeve.

Troubleshooting Tips:

Always use the correct measuring tools and techniques. Accuracy is critical when assessing cylinder geometry. Improper measurements can lead to misdiagnosis and incorrect repairs.

Pay attention to the cylinder walls' surface finish. Scratches, scoring, or glazing can all indicate problems that need to be addressed.

Compare your measurements to the manufacturer's specifications. This will help you determine whether the cylinder is within acceptable tolerances.

Safety First: Risky Components and Procedures

Working with engine cylinders involves several safety considerations:

- Sharp Edges: Cylinder blocks and machined surfaces often have sharp edges that can cause cuts. Always wear gloves when handling these components.

- Heavy Lifting: Engine blocks can be extremely heavy. Use appropriate lifting equipment and techniques to avoid injury.

- Solvents and Chemicals: Cleaning solvents and machining fluids can be harmful if inhaled or come into contact with skin. Wear appropriate personal protective equipment (PPE), such as gloves, eye protection, and a respirator, when working with these materials.

- Machining Hazards: Machining operations like boring and honing generate metal chips and dust. Wear safety glasses and a dust mask to protect your eyes and respiratory system.

Specifically concerning the cylinders, the biggest risk comes from improper use of tools for working on them. Attempting to hone a cylinder without proper experience, for example, can lead to catastrophic damage, rendering the block useless. The cylinder *must* be handled and worked on carefully.

So, Back to the Original Question: Sides vs. Surfaces

While a mathematician might say a cylinder has three surfaces (one curved, two circular), in the context of an engine cylinder, we often simplify things. We usually focus on the single, continuous curved surface that makes up the cylinder wall itself. This is the surface that interacts directly with the piston rings and where combustion occurs. So, for practical purposes, you can think of an engine cylinder as having one main working "side." That said, for many applications, understanding the flat faces are critical!

We've covered a lot here, from basic geometry to practical troubleshooting. Remember, understanding the fundamental principles of cylinder geometry is crucial for effective engine repair and modification. Armed with this knowledge, you can approach engine work with greater confidence and precision.

To further assist in your projects, we've compiled a detailed technical diagram of a typical engine cylinder, complete with dimensions, tolerances, and material specifications. Feel free to download it here. This diagram provides a valuable reference point for your repair and modification endeavors.