How Many Sides Has A Cylinder

Alright, let's tackle a question that might sound a bit odd at first: How many sides does a cylinder have? You might be thinking "What? A cylinder doesn't have *sides*!" But stick with me. From a mathematical perspective, and more importantly, from a practical point of view in understanding engine components and other cylindrical parts in your car, the answer might surprise you. We're not talking about flat planes like a cube. We're dealing with something more nuanced, involving surfaces and topology.

Why This Matters: Beyond Geometry Class

This isn't just about recalling high school geometry. Understanding the surfaces that make up a cylinder is crucial for several reasons in automotive repair and modification:

Sealing Surfaces: Think about piston rings sealing against the cylinder walls in your engine. Understanding the surface properties of the cylinder is paramount for proper compression and preventing oil blow-by.

Component Fitment: Many automotive parts, like bushings, sleeves, and even certain engine components, are cylindrical. Knowing how these parts interact with other surfaces, specifically the *curved* surface of a cylinder, is essential for proper installation and function.

Fluid Dynamics: In components like brake master cylinders or hydraulic pumps, the cylindrical shape is critical to how fluids move. Understanding the geometry helps diagnose problems related to flow restriction or leakage.

Manufacturing and Machining: When modifying or rebuilding engines, you might need to machine or hone cylinder bores. Understanding the 3D shape is critical for accurate material removal and achieving the desired surface finish.

Key Specs and Main Parts of a Cylinder (Simplified View)

For our purposes, let's consider a idealized, perfect cylinder. This is crucial for the mathematical discussion. In the real world, imperfections are inevitable, but the ideal case provides a solid foundation.

Key Components:

- Cylindrical Surface: This is the main, curved surface that wraps around the central axis. It's technically considered one continuous surface.

- Top Circular Face: One of the circular end caps.

- Bottom Circular Face: The other circular end cap, parallel to the top face.

Key Specs (Assuming a Right Circular Cylinder):

- Radius (r): The distance from the center of the circular face to any point on the edge of the circle.

- Height (h): The distance between the two circular faces. Also referred to as length of the cylinder.

- Diameter (d): The distance across the circular face through the center point. (d = 2r)

- Surface Area: The total area of all the surfaces of the cylinder. This includes the curved surface and the two circular faces.

- Volume: The amount of space enclosed within the cylinder.

Mathematically, the surface area of a cylinder is calculated as: 2πrh + 2πr². The volume is πr²h.

So, How Many Sides? The Twist...

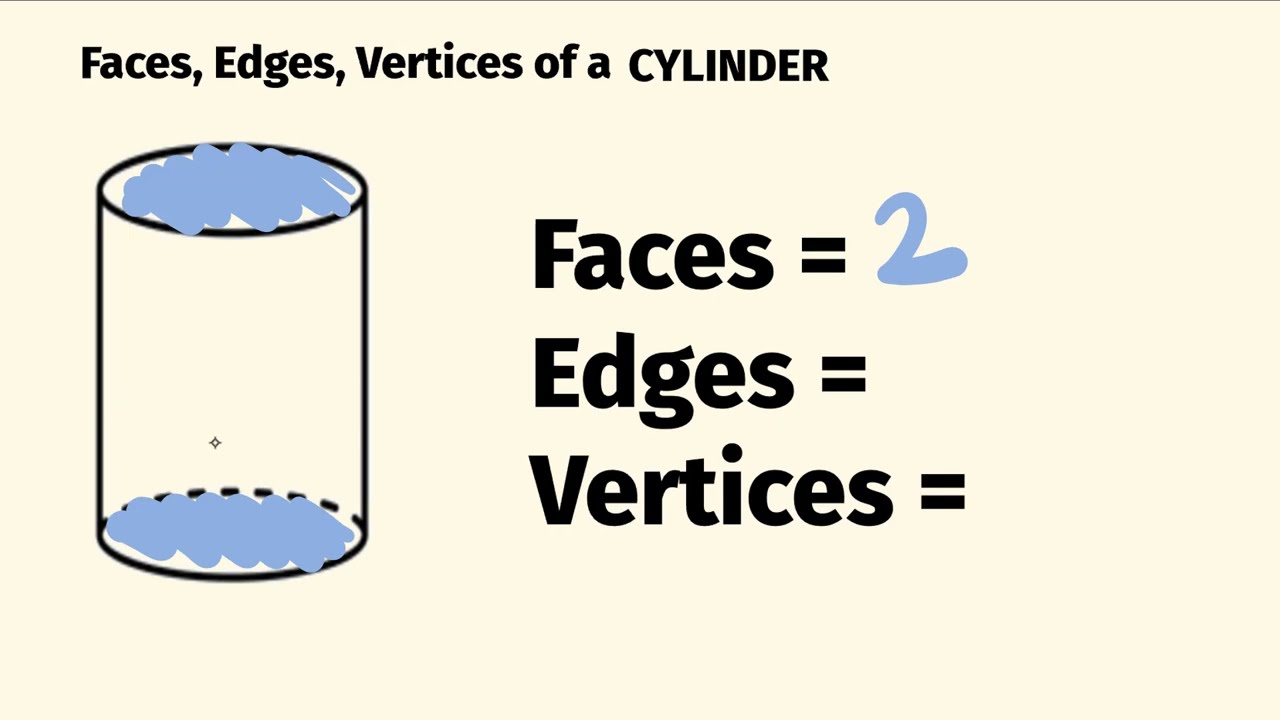

Now, the tricky part. If you consider a "side" to be a flat, planar surface, then a cylinder has zero sides. However, if we consider a 'side' as a *surface*, then we must consider:

- Two circular faces: These are planar, so we can consider them as two "sides".

- One curved surface: This is where it gets interesting. This surface isn't flat, but it *is* a distinct surface bounding the cylinder.

Therefore, from a topological standpoint, a cylinder effectively has three sides: two flat circular ends, and one continuous curved surface. The key is the definition of a "side." In everyday language, we usually think of flat sides. Mathematically, however, a *surface* counts.

How It Works (In Automotive Context)

Think about a piston moving up and down inside an engine cylinder. The piston rings are designed to maintain a seal against the cylindrical surface. This requires extremely precise machining and a smooth surface finish. If the cylinder walls are scored or worn, the piston rings won't seal properly, leading to:

- Loss of Compression: Reduced power, poor fuel economy, and difficulty starting.

- Oil Blow-By: Oil leaking past the piston rings and burning in the combustion chamber, resulting in blue smoke from the exhaust.

- Engine Knock: Improper combustion due to low compression can lead to knocking and potentially damage the engine.

This is why honing is performed. Honing is a machining process that creates a very fine, controlled surface finish on the cylinder walls to optimize the seal between the piston rings and the cylinder. The honing process creates a cross-hatch pattern that helps retain oil and aids in lubrication.

Real-World Use: Basic Troubleshooting Tips

Here are a few basic troubleshooting tips related to cylindrical components:

- Cylinder Leak-Down Test: This test measures the amount of air leaking past the piston rings. It helps diagnose worn cylinders, damaged rings, or leaky valves. You'll need a leak-down tester, which connects to the spark plug hole and pressurizes the cylinder.

- Visual Inspection: When rebuilding an engine, carefully inspect the cylinder walls for signs of scoring, wear, or damage. Look for a consistent crosshatch pattern if the cylinders have been honed previously. If the crosshatch is gone, it indicates significant wear.

- Cylinder Bore Measurement: Use a cylinder bore gauge to measure the diameter of the cylinder at various points. This will help determine if the cylinder is out-of-round or tapered, which can indicate excessive wear and necessitate re-boring or sleeving the cylinder.

- Brake Master Cylinder Inspection: Check for leaks around the master cylinder. A leaking master cylinder can cause brake failure. Inspect the inside of the cylinder for scoring and pitting, which can compromise the seals.

Safety Considerations

When working with cylindrical components, especially in engines and braking systems, remember these safety tips:

- Depressurize Systems: Always depressurize hydraulic systems (like brakes) before working on them.

- Use Proper Tools: Use the correct tools for the job. Improper tools can damage components and cause injury.

- Wear Safety Glasses: Protect your eyes from flying debris and chemicals.

- Handle Fluids Carefully: Brake fluid and engine oil are hazardous. Wear gloves and avoid skin contact. Dispose of fluids properly.

- High Pressure Risks Hydraulic components such as ABS modules and power steering racks often are filled with high pressure liquids which can cause injury if not properly relieved before disassembly.

Specifically when working on cylinders themselves within the engine, keep these additional safety notes in mind:

- Sharp Edges: When boring cylinders, pay attention to the edges that form upon cutting the metal. These edges can be sharp and cause lacerations.

- Proper Lifting Techniques: Engine blocks, and even individual cylinders can be extremely heavy. Make sure to use proper lifting techniques and lifting equipment to prevent injury.

Understanding the geometry of a cylinder and its role in various automotive systems is crucial for effective diagnosis, repair, and modification. While the question of "how many sides" might seem trivial at first, it highlights the importance of understanding the underlying principles of these components.

We have a detailed technical drawing of a typical engine cylinder that you can download. This diagram includes dimensions, surface finish specifications, and other relevant information. It's a great resource for understanding the intricacies of cylinder design and construction.