How Much Does A Engine Weigh

So, you’re thinking about yanking an engine out of a car, swapping it, or maybe just curious about the heft you’re dealing with. A perfectly reasonable question is: How much does an engine weigh? The answer, unsurprisingly, is "it depends," but let’s dive into the factors that determine engine weight and how you can get a good estimate for your specific situation.

Purpose: Why Engine Weight Matters

Understanding engine weight isn't just trivia; it's crucial for several reasons:

- Engine Swaps: When swapping engines, weight differences can significantly affect handling, braking, and overall vehicle balance. Going too heavy can overload the front suspension or throw off the car's center of gravity.

- Repair and Maintenance: Knowing the approximate weight allows you to select appropriate lifting equipment (engine hoist, cherry picker) and secure anchoring points. You don't want to risk a catastrophic failure due to using inadequate tools.

- Performance Modifications: Modifying engine components (e.g., replacing a cast iron block with an aluminum one) is often done to reduce weight and improve performance. Knowledge is power!

- Transportation: If you're shipping an engine, accurate weight information is vital for calculating shipping costs and ensuring safe handling.

Key Specs and Main Parts Affecting Engine Weight

Engine weight is affected by several design choices and materials. Here's a breakdown:

Block Material

This is arguably the biggest contributor to engine weight. The engine block is the main structural component that houses the cylinders, crankshaft, and other vital parts.

- Cast Iron: Cast iron blocks are incredibly durable and robust, making them suitable for high-stress applications like heavy-duty trucks and older performance cars. However, they are significantly heavier than aluminum blocks. Expect a cast iron block to add a substantial amount of weight.

- Aluminum: Aluminum blocks offer a significant weight reduction compared to cast iron. They are common in modern passenger cars and performance vehicles to improve fuel economy and handling. However, aluminum isn't as inherently strong as cast iron, so manufacturers often employ techniques like reinforced cylinder liners to improve durability.

Engine Configuration

The engine configuration also plays a role. More cylinders and complex designs generally translate to more weight.

- Inline Engines (I4, I6): These are typically lighter than V-shaped engines due to their simpler construction and fewer parts.

- V-Engines (V6, V8, V10, V12): These are more compact in length than inline engines with the same number of cylinders, but they tend to be wider and heavier due to the added complexity of the cylinder banks and related components.

- Flat Engines (Boxer engines): These engines, like those found in Subarus and some Porsches, offer a low center of gravity and unique characteristics. Their weight varies depending on the materials and cylinder count.

Engine Displacement

Larger displacement (measured in liters or cubic inches) generally means a larger engine block and heavier internal components, leading to greater weight. A 5.0L V8 will almost always be heavier than a 2.0L inline-4, all other factors being equal.

Attached Components

Don't forget about the peripherals! The weight of an engine *assembly* includes all the bolted-on parts:

- Cylinder Heads: Cast iron or aluminum, impacting weight significantly.

- Intake Manifold: Aluminum or plastic; aluminum is generally heavier.

- Exhaust Manifold/Headers: Cast iron or stainless steel; another substantial weight contributor.

- Alternator, Starter, Power Steering Pump, Air Conditioning Compressor: These accessories add a noticeable amount of weight.

- Flywheel/Flexplate: A heavy steel flywheel adds weight, especially crucial for manual transmissions.

- Oil Pan: Steel or aluminum; steel is usually heavier.

- Coolant: The weight of coolant is often overlooked, but a fully filled engine can easily add several pounds. Drain before lifting!

How It Works: Estimating Engine Weight

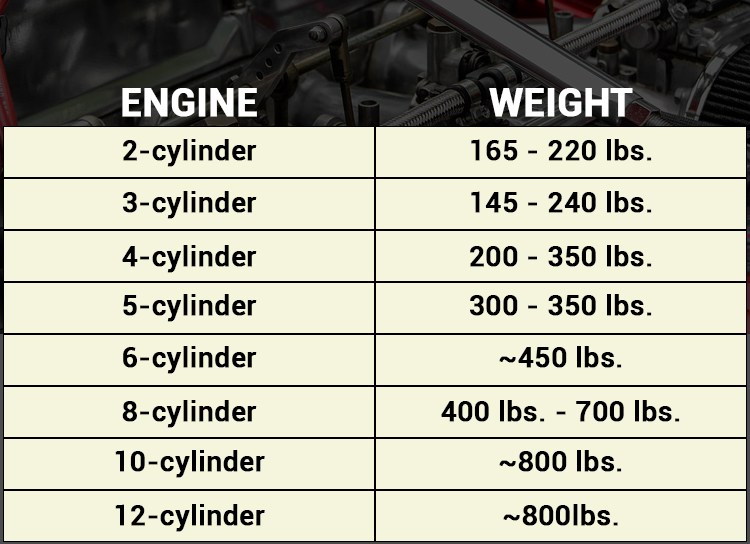

Finding the exact weight of an engine often requires searching online forums, manufacturer specifications (if available), or contacting engine builders. However, here are some general estimates:

- Small Inline-4 (1.6L - 2.5L): 250 - 350 lbs (113 - 159 kg)

- Large Inline-4 (2.5L+): 300 - 400+ lbs (136 - 181+ kg)

- Small V6 (2.5L - 3.5L): 300 - 400 lbs (136 - 181 kg)

- Large V6 (3.5L+): 350 - 450+ lbs (159 - 204+ kg)

- Small V8 (4.0L - 5.0L): 450 - 600 lbs (204 - 272 kg)

- Large V8 (5.0L+): 550 - 700+ lbs (249 - 318+ kg)

Remember: These are just estimates. Always verify with more specific information if possible. A "dressed" engine (with all accessories) will weigh considerably more than a "bare" engine (just the block, heads, and basic internals).

Real-World Use: Basic Troubleshooting Tips

Engine weight plays a role in troubleshooting, particularly when diagnosing suspension issues:

- Sagging Front Suspension: If you notice excessive sagging in the front suspension after an engine swap, it could indicate that the new engine is too heavy for the original springs. Consider upgrading the springs to handle the added weight.

- Handling Problems: A significant weight imbalance can lead to poor handling. The car might feel nose-heavy or unstable in corners. Weight distribution can be improved with careful component selection and placement.

- Engine Mount Issues: Over time, engine mounts can deteriorate. A heavier engine will accelerate this process. Inspect engine mounts regularly and replace them if they show signs of cracking or wear.

Safety: Risky Components and Procedures

Working with engines is inherently dangerous. Here are crucial safety precautions:

- Lifting Equipment: Never use damaged or undersized lifting equipment. Always inspect your engine hoist, chains, and slings for wear and tear before each use.

- Secure Anchoring: Ensure that the engine is securely attached to the hoist using appropriate lifting points. Consult the engine's service manual for recommended lifting points.

- Personal Protective Equipment (PPE): Wear safety glasses, gloves, and steel-toed boots to protect yourself from potential hazards.

- Stable Work Area: Work in a well-lit and level area. Ensure that the vehicle is properly supported on jack stands before working underneath it.

- Flammable Liquids: Be extremely careful when handling flammable liquids like gasoline or oil. Keep them away from heat sources and open flames.

- Battery Disconnection: Always disconnect the negative battery terminal before working on the engine's electrical system.

In Conclusion

Understanding engine weight is a critical aspect of engine swaps, repairs, and performance modifications. By considering the factors discussed above and using reliable sources for weight information, you can ensure a safe and successful project. Remember to prioritize safety at all times and use the appropriate tools and equipment.

We have a detailed engine diagram file that can assist you. The diagram provides a visual representation of various engine components and their relative sizes, which can help estimate weight distribution. The reader can download the diagram to get a more comprehensive understanding. Please contact us via email.