How Much Does A V8 Cost

So, you're thinking about getting your hands dirty with a V8, huh? Whether you're looking to replace a blown engine, upgrade your ride for more power, or just understand what goes into these iconic powerplants, the question inevitably arises: How much does a V8 cost? The answer, as you might expect, is complex and depends on a multitude of factors.

Purpose: Beyond Just the Price Tag

Understanding the cost factors associated with a V8 engine goes far beyond just writing a check. Knowledge of these costs empowers you to make informed decisions about your project, whether it's a straightforward replacement or a complex custom build. This knowledge also aids in proper maintenance, preventing future costly repairs. For the DIY mechanic, knowing the price of components helps with budgeting, sourcing parts, and even negotiating with suppliers. The information helps in determining whether you rebuild or replace the engine altogether.

Key Specs and Main Parts: A V8 Anatomy Lesson

Let's break down the essential components and specifications that influence the cost of a V8 engine.

Key Specs:

- Displacement: Measured in cubic inches (ci) or liters (L), displacement refers to the total volume swept by all the pistons in the engine cylinders. Larger displacement generally equates to more power, but also higher cost. Think a 302ci small block Chevy versus a 454ci big block.

- Horsepower and Torque: These power output metrics directly correlate with the engine's capabilities. Higher horsepower and torque ratings often come with premium price tags due to more sophisticated engineering and stronger components.

- Engine Family: Is it a Chevy LS series, a Ford Coyote, a Mopar Hemi, or something else entirely? Each family has its own strengths, weaknesses, and associated costs for parts and labor.

- Year and Model: Older engines may be cheaper to acquire but harder to find parts for, while newer, high-performance models will generally command a higher price.

- Condition: A brand new crate engine will cost significantly more than a used engine pulled from a salvage yard. Rebuilt or remanufactured engines fall somewhere in between.

Main Parts and Their Cost Drivers:

- Engine Block: The foundation of the engine. Cast iron blocks are generally less expensive than aluminum blocks, which offer weight savings. A brand new, aftermarket block can be a significant investment.

- Cylinder Heads: Critical for airflow and combustion efficiency. Aluminum heads are generally more expensive than cast iron heads but provide better performance due to improved heat dissipation. Porting and polishing cylinder heads can further increase performance but also adds to the cost.

- Crankshaft, Connecting Rods, and Pistons (Rotating Assembly): These components must be strong enough to withstand the forces generated by combustion. Forged components are significantly stronger and more expensive than cast components, making them desirable for high-performance applications. Balancing the rotating assembly is essential for smooth operation and longevity.

- Camshaft: Controls the timing of the valves. Different camshaft profiles can dramatically alter the engine's performance characteristics. Roller camshafts are generally more expensive and offer better performance and durability than flat-tappet camshafts.

- Intake Manifold: Distributes the air-fuel mixture to the cylinders. Aftermarket intake manifolds can improve airflow and increase power, but they come at a cost.

- Fuel System: Supplies the engine with fuel. Carburetors are generally less expensive than fuel injection systems, but fuel injection offers better fuel economy and emissions control. Upgrading to larger fuel injectors and a higher-capacity fuel pump may be necessary for high-performance applications.

- Ignition System: Ignites the air-fuel mixture in the cylinders. Upgrading to a high-performance ignition system can improve spark energy and combustion efficiency.

- Exhaust System: Removes exhaust gases from the cylinders. Headers and a performance exhaust system can improve exhaust flow and increase power.

Cost Factors in Detail

The price of a V8 engine can range wildly. A used, standard small-block Chevy 350 from a salvage yard might cost a few hundred dollars, while a brand new, high-performance crate engine from a reputable manufacturer can easily exceed $15,000 or even $20,000. Here's a deeper dive into the cost influencers:

- New vs. Used vs. Rebuilt: A new "crate" engine is the most expensive option, but offers the peace of mind of a warranty and zero wear. Used engines are the cheapest, but come with the risk of unknown condition and potential hidden issues. Rebuilt engines offer a middle ground, having been disassembled, cleaned, inspected, and reassembled with new or refurbished parts. Look for a reputable rebuilder with a warranty.

- Brand and Reputation: Established engine builders like GM Performance, Ford Performance, and Mopar Performance often command a premium due to their reputation for quality and performance. Aftermarket builders can offer competitive pricing, but do your research and check reviews.

- Complexity and Features: Modern V8s with advanced technologies like direct injection, variable valve timing, and supercharging will generally be more expensive than older, simpler designs.

- Labor Costs: If you're not doing the work yourself, factor in the cost of labor for installation. This can vary depending on the complexity of the swap and the hourly rate of the mechanic.

- Additional Components: Don't forget about the other components you'll need for the swap, such as engine mounts, wiring harnesses, cooling systems, and exhaust systems. These can add significantly to the overall cost.

Real-World Use: Basic Troubleshooting Tips

Even with a new or rebuilt engine, problems can arise. Here are a few basic troubleshooting tips:

- Rough Idle: Could be caused by vacuum leaks, faulty spark plugs, or a malfunctioning idle air control (IAC) valve.

- Lack of Power: Could be caused by a clogged fuel filter, a weak fuel pump, or a malfunctioning mass airflow (MAF) sensor.

- Overheating: Could be caused by a low coolant level, a faulty thermostat, or a clogged radiator.

- Oil Leaks: Common areas for oil leaks include the valve covers, oil pan, and rear main seal.

- Knocking or Pinging: Could be caused by low octane fuel, excessive carbon buildup, or a lean air-fuel mixture.

Safety: Respect the Power

Working on engines, especially high-performance V8s, requires caution. Some components pose specific risks:

- High-Pressure Fuel Systems: Fuel injection systems operate at high pressures. Always relieve pressure before disconnecting fuel lines.

- Electrical Systems: Disconnect the battery before working on the electrical system. Capacitors in the ignition system can hold a dangerous charge.

- Hot Surfaces: Exhaust manifolds and other engine components can get extremely hot. Wear gloves and allow the engine to cool before working on it.

- Rotating Parts: Keep your hands and clothing away from rotating parts, such as the crankshaft and camshaft.

- Heavy Components: Engine blocks and cylinder heads are heavy and can cause serious injury if dropped. Use proper lifting equipment and techniques.

Remember to consult a qualified mechanic if you are uncomfortable performing any of these tasks. Your safety, and the longevity of your V8, depends on it!

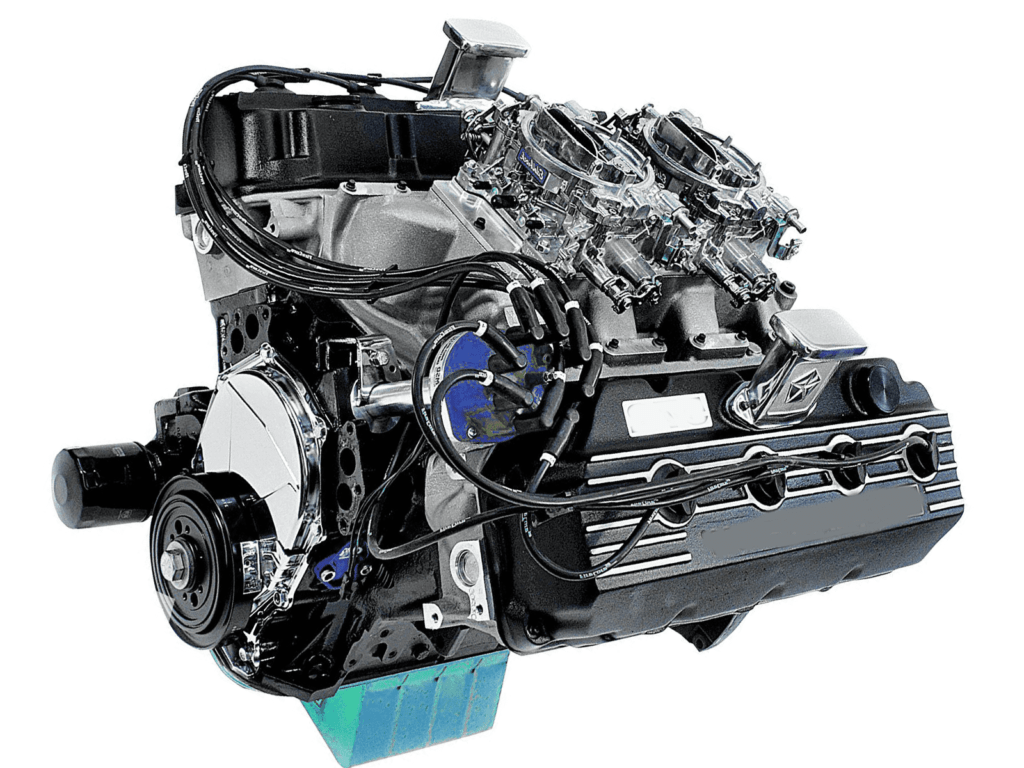

We've Got the Diagram

We have a detailed V8 engine diagram file available for download, encompassing major systems and components. This resource is invaluable for visual learners and can assist in identification, repair, and modification projects. To download the diagram, simply [link to download] after verifying your account.