How Much Does A V8 Engine Weigh

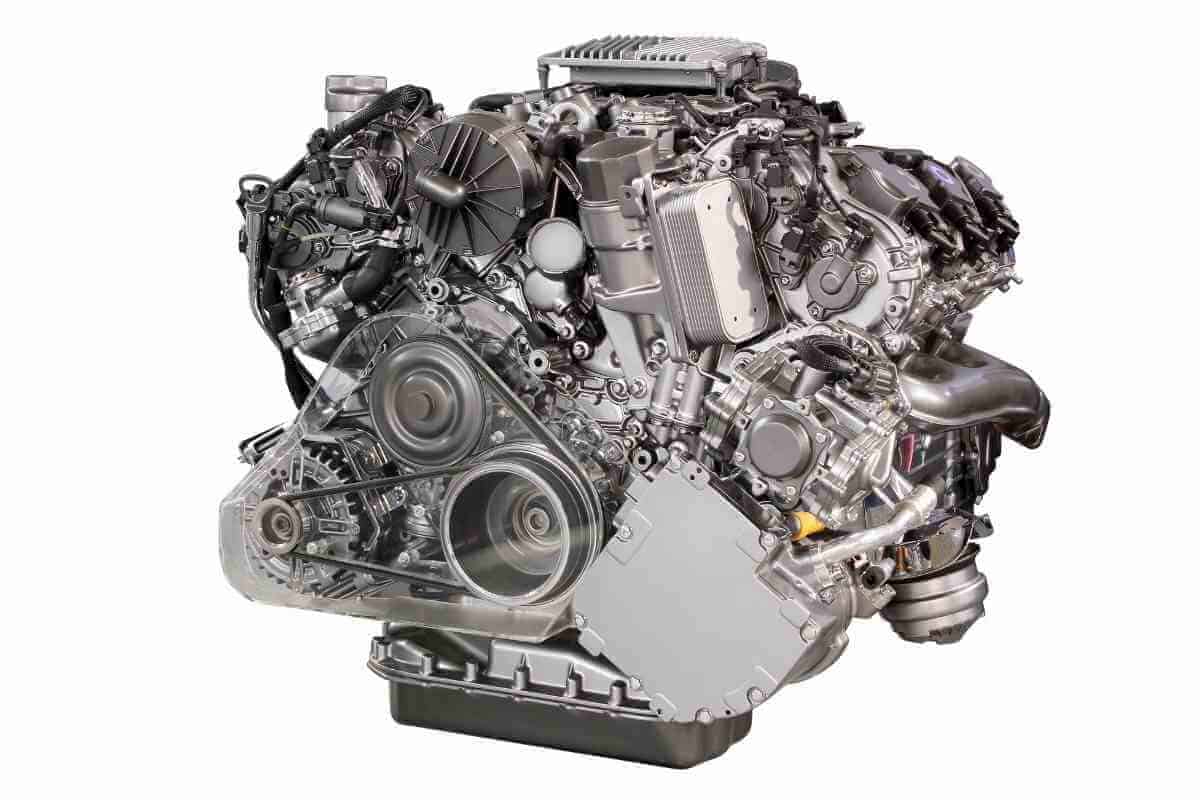

Alright, let's talk about something fundamental to any V8 project, be it an engine swap, performance upgrade, or simply understanding the beast under the hood: the weight of a V8 engine. It's a deceptively simple question with a surprisingly complex answer, dependent on displacement, materials, and included accessories. We're diving deep, so grab a wrench and let's get started. This guide is aimed at experienced DIYers who are comfortable with automotive terminology and procedures.

Why Does V8 Engine Weight Matter?

Knowing your V8's weight is crucial for several reasons:

- Vehicle Compatibility: Engine swaps are popular, but dropping a significantly heavier engine into a chassis not designed for it can negatively impact handling, suspension, and even structural integrity. Overloading the front axle can compromise steering and braking.

- Performance Calculations: Power-to-weight ratio is a cornerstone of performance. Knowing the engine's weight allows you to accurately assess how much of an improvement a new engine provides.

- Transportation and Handling: Moving an engine safely requires the right equipment. Using an engine hoist rated for 500 lbs on a 700 lb engine is a recipe for disaster.

- Suspension Tuning: Changing the engine weight necessitates adjusting the suspension accordingly to maintain proper ride height and handling characteristics.

- General Knowledge: Understanding the mass of key components enhances your overall automotive knowledge.

Key Specs and Main Parts Contributing to Weight

The weight of a V8 engine varies widely, but here's a breakdown of factors and typical weights for common configurations:

Displacement

Displacement, measured in cubic inches (CID) or liters (L), is the total volume swept by all the pistons within the cylinders. Larger displacement generally means more material and, therefore, greater weight. A small-block V8 (typically under 400 CID/6.6L) will generally weigh less than a big-block V8 (typically over 400 CID/6.6L). For example, a GM LS1 (5.7L) weighs significantly less than a Ford 460 (7.5L).

Engine Block Material

The engine block is the foundation of the engine, housing the cylinders, crankshaft, and other critical components. The material it's made from drastically impacts weight:

- Cast Iron: Traditional cast iron blocks are durable and relatively inexpensive, but they are also the heaviest. A typical cast iron small-block V8 can weigh between 550-650 lbs (fully dressed – more on that later). Big-block iron engines can reach 700-800 lbs or more.

- Aluminum: Aluminum blocks offer significant weight savings compared to cast iron, often shedding 100-200 lbs. However, aluminum is more expensive and can be less durable under extreme conditions (though modern aluminum alloys have improved greatly). A typical aluminum small-block V8 might weigh 400-500 lbs.

Cylinder Heads

Cylinder heads sit atop the engine block and house the valves, valve springs, and combustion chambers. Like the block, cylinder heads can be made from cast iron or aluminum, influencing overall weight.

Rotating Assembly

The rotating assembly includes the crankshaft, connecting rods, and pistons. While lighter components can improve performance, the material of these parts doesn't contribute as significantly to the overall engine weight compared to the block or heads.

"Dressed" vs. "Bare" Weight

This is critical! An engine's weight is often quoted in two ways:

- Bare Weight: This is the weight of the engine block, cylinder heads, and internal components (crankshaft, pistons, etc.) without any external accessories.

- Dressed Weight: This is the weight of the engine with all (or most) of its accessories attached, including the intake manifold, carburetor or fuel injection system, exhaust manifolds, alternator, starter, water pump, power steering pump, and sometimes even the air conditioning compressor.

Always look for the "dressed" weight when planning a swap or project, as this is the actual weight you'll be dealing with.

How It Works: A Weight Breakdown

Let's consider a typical small-block Chevy 350 (5.7L) to illustrate a weight breakdown:

- Cast Iron Block: ~180 lbs

- Cast Iron Cylinder Heads: ~50 lbs each (100 lbs total)

- Rotating Assembly: ~75 lbs

- Intake Manifold (Aluminum): ~25 lbs

- Carburetor: ~10 lbs

- Exhaust Manifolds: ~30 lbs each (60 lbs total)

- Water Pump: ~10 lbs

- Alternator: ~15 lbs

- Starter: ~10 lbs

- Other Accessories (brackets, hoses, etc.): ~25 lbs

Adding these up, we get a total dressed weight of approximately 530 lbs. This is a rough estimate, and specific component weights can vary. Swapping to aluminum heads would shave off around 50 lbs, bringing the total down to approximately 480 lbs.

Real-World Use: Basic Troubleshooting Tips Related to Weight

Engine weight can be a factor in troubleshooting various issues:

- Excessive Front-End Sag: If you notice a significant sag in the front suspension after an engine swap, it could indicate that the new engine is too heavy for the original springs. Upgrading to stiffer springs is often necessary.

- Poor Handling: A significantly heavier engine can negatively impact handling, leading to understeer or oversteer. Addressing this may require adjusting the suspension, tire pressure, or even relocating weight within the vehicle.

- Engine Mount Failure: Repeated stress from an overly heavy engine can cause engine mounts to fail prematurely. Ensure that the engine mounts are rated for the engine's weight.

Safety: Risky Components and Handling

Engines are heavy and potentially dangerous. Always follow these safety precautions:

- Use Proper Lifting Equipment: Always use an engine hoist with a weight rating significantly exceeding the engine's weight. Inspect the hoist and chains for damage before each use.

- Secure the Engine Properly: Use a load-leveling device to ensure the engine is balanced during lifting. Secure the engine with chains or straps rated for the weight.

- Work on a Level Surface: Lifting an engine on an uneven surface can create instability and increase the risk of tipping.

- Keep Clear of the Load: Never stand under a suspended engine.

- Disconnect the Battery: Before working on the engine, disconnect the negative battery cable to prevent accidental electrical shocks.