How Much Does A V8 Engine Weight

Alright, let's talk about the weight of a V8 engine. This might seem like a simple question, but the answer is "it depends." It depends on a lot of things. We're going to dive deep into the factors that influence V8 engine weight and give you a good ballpark estimate, along with the important considerations you need to make when working with these powerful beasts. Knowing the weight is crucial for everything from engine swaps and choosing the right hoist to ensuring your vehicle's suspension can handle the added mass. So, grab your wrench (figuratively speaking!), and let's get started.

Why Weight Matters

Knowing the approximate weight of a V8 engine is important for several reasons. Consider these common scenarios:

- Engine Swaps: Planning an engine swap? You absolutely need to know the weight of the new engine to ensure it's compatible with your vehicle's chassis and suspension. Overloading the front end can significantly impact handling and safety.

- Hoisting and Lifting: Choosing the right engine hoist is critical. Using an under-rated hoist is extremely dangerous. You need to know the approximate weight to select the proper equipment.

- Vehicle Modifications: If you are doing any mods, consider the weight.

- Suspension Upgrades: Adding a heavier engine might necessitate upgrading your suspension components, such as springs and shocks, to maintain proper ride height and handling.

- General Knowledge: Sometimes, it's just good to know! Understanding the relative weight of different engine types is part of becoming a more knowledgeable car enthusiast.

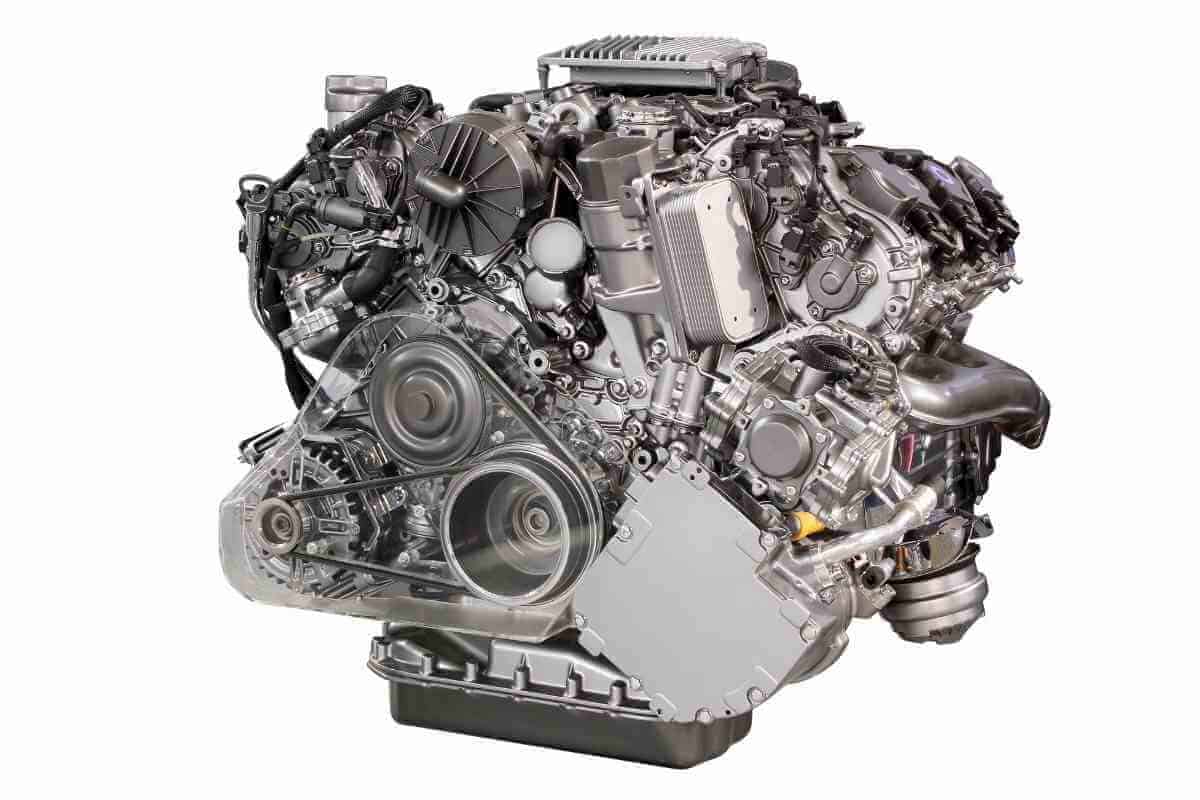

Key Specs and Main Parts Influencing Weight

The weight of a V8 engine varies depending on several factors, primarily its displacement (size), the materials used in its construction, and whether it's a "bare" engine or a "dressed" engine. Let's break it down:

Displacement

Larger displacement engines generally weigh more. A 302 cubic inch (5.0L) V8 will typically be lighter than a 454 cubic inch (7.4L) V8. More displacement generally means larger cylinders, pistons, connecting rods, and a beefier crankshaft, all contributing to increased weight. The displacement refers to the total volume swept by all the pistons inside the cylinders during one complete stroke.

Materials

The materials used in the engine's construction significantly affect its weight. There are two main categories:

- Cast Iron: Older V8 engines, and some newer ones, often use cast iron for the engine block and cylinder heads. Cast iron is durable and relatively inexpensive, but it's heavy.

- Aluminum: Modern V8 engines increasingly use aluminum for the engine block, cylinder heads, and intake manifold. Aluminum is significantly lighter than cast iron, leading to substantial weight savings.

"Bare" vs. "Dressed" Engine

It's crucial to distinguish between a "bare" engine and a "dressed" engine.

- Bare Engine: This refers to the engine block, cylinder heads, crankshaft, pistons, connecting rods, camshaft, and valvetrain – essentially the core engine components. A "bare" engine does not include accessories.

- Dressed Engine: This includes all the accessories attached to the engine, such as the intake manifold, exhaust manifolds (or headers), water pump, alternator, starter motor, power steering pump, air conditioning compressor, and wiring harness. These accessories can add a significant amount of weight.

Typical Weight Ranges

Here's a general guideline, keeping in mind that these are estimates and can vary:

- Small Block V8 (e.g., 302, 350):

- Bare (Cast Iron Block/Heads): 500-575 lbs

- Dressed (Cast Iron Block/Heads): 575-650 lbs

- Bare (Aluminum Block/Heads): 375-450 lbs

- Dressed (Aluminum Block/Heads): 450-525 lbs

- Big Block V8 (e.g., 454, 460):

- Bare (Cast Iron Block/Heads): 625-700 lbs

- Dressed (Cast Iron Block/Heads): 700-800 lbs

- Modern Aluminum V8 (e.g., LS series, Coyote):

- Bare (Aluminum Block/Heads): 400-475 lbs

- Dressed (Aluminum Block/Heads): 475-550 lbs

How It Works (Weight Distribution and Center of Gravity)

Understanding how the weight is distributed within the engine is also vital. The crankshaft, for example, is a relatively heavy component located low in the engine, contributing to a lower center of gravity. Conversely, the cylinder heads, especially those made of cast iron, add weight higher up. A lower center of gravity generally improves handling and stability.

When installing an engine, also consider the engine's center of gravity relative to the vehicle's existing center of gravity. A drastically different center of gravity can affect handling. You can adjust for this with suspension and chassis modifications.

Real-World Use: Basic Troubleshooting and Weight Reduction

Here are some real-world scenarios where knowing engine weight comes in handy:

- Identifying Excessive Sag: If you notice excessive sagging in your vehicle's front end after an engine swap, it's a clear sign that the engine is too heavy for the existing suspension. You'll need to upgrade the springs and shocks to compensate.

- Diagnosing Handling Issues: If your vehicle handles poorly after an engine modification, the engine's weight distribution might be to blame. Consider relocating some components or adjusting the suspension to correct the balance.

- Weight Reduction Strategies: Enthusiasts often seek ways to reduce engine weight to improve performance. Common strategies include using an aluminum intake manifold, lightweight headers, or even switching to an aluminum block and heads. Also, a lightweight flywheel or harmonic balancer helps improve acceleration.

Safety: Handling Heavy Engines

Working with heavy engines is inherently dangerous. Safety should always be your top priority. Here are some crucial safety precautions:

- Use the Right Equipment: Always use an engine hoist that is rated for the engine's weight, with a safety factor built in. Double-check the hoist's rating and inspect it for any signs of damage before each use. Using a hoist with inadequate capacity is extremely dangerous.

- Secure the Engine Properly: Use a proper engine lifting plate or chains to secure the engine to the hoist. Make sure the attachment points are strong and secure.

- Work in a Safe Environment: Ensure that the work area is clear of obstructions and that the floor is level and stable.

- Get Help: Don't try to lift or move a heavy engine alone. Have at least one other person assist you.

- Wear Safety Gear: Always wear safety glasses, gloves, and steel-toed boots when working with engines.

- Fuel and Oil: Be extra careful about fuel and oil. If these liquids spill on a hot engine component (like exhaust manifold) they could cause a fire.

By understanding the factors that influence V8 engine weight and taking appropriate safety precautions, you can confidently tackle engine swaps and modifications. Now that you know how to estimate the weight, you can approach your projects with greater confidence.