How Much Is A V8 Engine

Alright, let's talk V8 engines and, more specifically, the question everyone asks: How much are they really gonna set you back? As an experienced DIYer, you know it's not a simple answer. It's not like buying a spark plug. There's a huge range, influenced by age, condition, performance, and where you're getting it from. This article breaks down the cost factors associated with V8 engines, assuming you're not just interested in buying one, but in understanding the value proposition.

Purpose: Why Understanding V8 Engine Costs Matters

Knowing the ins and outs of V8 engine pricing isn't just about haggling. It's about making informed decisions for your projects. Whether you're planning a resto-mod, swapping an engine for more power, or simply needing to replace a tired V8, understanding these costs can help you:

- Budget accurately: Avoid nasty surprises down the road.

- Evaluate deals: Spot a bargain or recognize a rip-off.

- Prioritize repairs: Understand which repairs are cost-effective vs. when it's time for a replacement.

- Make informed modification choices: A supercharger on a tired engine might not be the wisest investment.

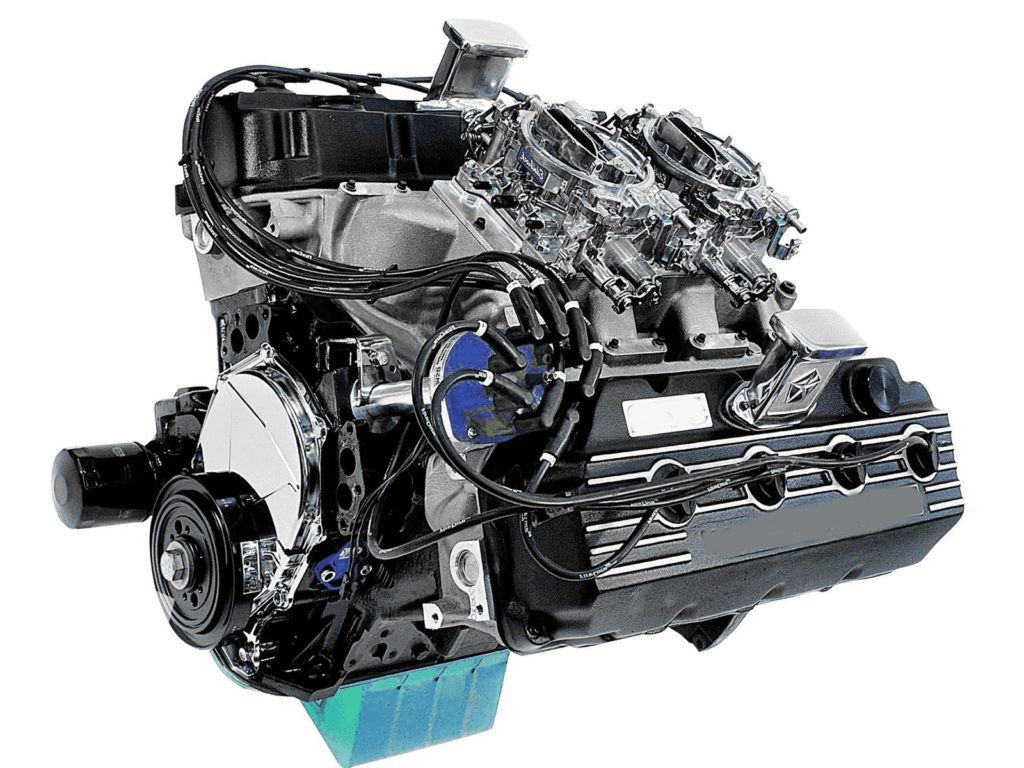

Key Specs and Main Parts Affecting Price

The price of a V8 engine is significantly impacted by its specifications and the condition of its main components. Here's a breakdown:

Engine Type & Displacement:

A brand new, crate engine from GM (like an LS3) or Ford (like a Coyote) will always be more expensive than a used engine pulled from a junkyard. Displacement (measured in cubic inches or liters) plays a significant role. Larger displacement often translates to higher power output and, therefore, higher cost.

Examples:

- Small Block Chevy (SBC): 350 cubic inches (5.7L) is a very common and relatively affordable option.

- Big Block Chevy (BBC): 454 cubic inches (7.4L) is less common and pricier due to its larger size and potential for high horsepower.

- Ford Coyote: 5.0L modern engine, known for its high-revving capability and is relatively expensive compared to older pushrod V8s.

- Chrysler Hemi: Typically larger displacement (5.7L, 6.1L, 6.4L), known for performance, and generally command a higher price.

Engine Condition:

This is arguably the biggest factor. A rebuilt engine, professionally overhauled with new components, will be more expensive than a used engine "pulled" from a vehicle. A core engine, needing a full rebuild, will be the cheapest but requires significant investment and expertise.

Main Parts:

- Block: The engine's foundation. Cracks or damage here can render the engine unusable.

- Cylinder Heads: Significantly impact airflow and power. Aluminum heads are generally more expensive than cast iron.

- Crankshaft: The heart of the engine, converting linear motion to rotational motion. Forged crankshafts are stronger and pricier than cast crankshafts.

- Connecting Rods: Connect the pistons to the crankshaft. Upgraded rods are crucial for high-horsepower applications.

- Pistons: Move within the cylinders, compressing the air-fuel mixture. Forged pistons are stronger and pricier than cast pistons.

- Camshaft: Controls valve timing. Aftermarket camshafts can dramatically alter engine performance.

- Intake Manifold: Directs air into the cylinders. Aftermarket manifolds can improve airflow.

- Fuel System: Carbureted or Fuel Injected. EFI systems are generally more expensive but offer better performance and efficiency.

Where to Buy:

- Junkyards: Cheapest option, but high risk. Thorough inspection is crucial.

- Online Marketplaces (eBay, etc.): Wider selection, but buyer beware. Check seller ratings and ask detailed questions.

- Engine Rebuilders: Offer rebuilt engines with warranties, but more expensive than junkyard finds.

- Crate Engine Suppliers: Brand new engines, often with performance upgrades, but the most expensive option.

How It Works: V8 Engine Basics

The basic operating principle of a V8 engine is the same as any internal combustion engine: intake, compression, combustion (power), and exhaust. The "V8" configuration simply means there are two banks of four cylinders arranged in a "V" shape. This allows for a shorter engine block compared to an inline-eight, leading to better packaging in the engine bay. Each cylinder contains a piston that moves up and down, driven by the expansion of gases during combustion. The pistons are connected to the crankshaft via connecting rods, and the rotation of the crankshaft provides the power to turn the wheels.

Real-World Use: Basic Troubleshooting Tips When Buying Used

Buying a used V8 is always a gamble, but you can minimize the risk with some basic checks:

- Visual Inspection: Look for obvious signs of damage, such as cracks in the block or heads, excessive rust, or oil leaks.

- Crankshaft Rotation: Try to rotate the crankshaft by hand (with a wrench on the harmonic balancer). It should turn smoothly and without excessive resistance.

- Compression Test: If possible, perform a compression test on each cylinder. Low compression in one or more cylinders indicates potential problems.

- Oil Analysis: If the engine has oil, consider getting an oil analysis to check for contaminants like coolant or metal particles, which could indicate internal damage.

- Ask Questions: Ask the seller as many questions as possible about the engine's history, including how it was used, when it was last serviced, and why it's being sold.

Safety: Risky Components and Best Practices

Working on engines involves potential hazards. Here's a quick safety rundown:

- Lifting Heavy Components: Use proper lifting equipment (engine hoist, cherry picker) and secure the engine to the hoist properly. An engine falling can cause serious injury or death.

- Flammable Liquids: Gasoline, oil, and other fluids are highly flammable. Work in a well-ventilated area and keep sources of ignition away.

- Sharp Objects: Engine components often have sharp edges. Wear gloves to protect your hands.

- Chemicals: Use appropriate personal protective equipment (PPE) when handling cleaning solvents or other chemicals.

- Electrical System: Disconnect the battery before working on the electrical system to prevent shocks.

- Springs: Valve springs can be under considerable tension. Use a valve spring compressor to safely remove them.

Remember: If you're not comfortable with any aspect of engine work, it's best to consult a professional mechanic. Your safety is paramount.

Factors Influencing the Final Price

Besides the engine itself, consider these additional costs:

- Shipping: V8 engines are heavy and bulky. Shipping costs can be significant, especially for long distances.

- Installation: Unless you're doing the installation yourself, you'll need to factor in labor costs.

- Ancillary Components: You may need to purchase additional components, such as a new carburetor or fuel injection system, wiring harness, exhaust manifolds, etc.

- Tuning: Once the engine is installed, it may need to be tuned to optimize performance and ensure proper operation.

So, how much *is* a V8 engine? The answer is "it depends." A used SBC 350 from a junkyard could be as little as $500. A brand new, fully loaded LS7 crate engine could be upwards of $20,000. Doing your research, inspecting thoroughly, and understanding your needs are key to getting the best value for your money.