How Much Is A V8 Motor

Alright, let's talk about the elephant in the room – or rather, the V8 under the hood. How much does a V8 engine really cost? That's a question with a lot of variables, so we're going to break it down like a well-oiled machine, covering everything from core components to installation considerations.

Why Bother Understanding V8 Costs?

Knowing the price range of a V8 isn't just about budgeting for a project. It's about understanding the scope of work involved in swapping, rebuilding, or even just maintaining your current V8. Think about it: knowing whether that ticking noise is a $50 fix or a $5,000 rebuild will help you make informed decisions. Plus, if you're planning a performance upgrade, understanding the cost of different V8 platforms – like a small-block Chevy versus a Coyote – is crucial.

Key Specs and Main Parts That Influence Price

The cost of a V8 is heavily influenced by several factors, starting with its basic specs and the condition of its components. Here’s a rundown:

- Displacement: Simply put, the displacement is the total volume swept by all the pistons in the engine. Measured in cubic inches (ci) or liters (L), larger displacements generally mean higher prices, due to the increased material and machining required. A 350 ci small block will typically cost less than a 454 ci big block.

- Engine Condition: Obviously, a brand new crate engine will cost significantly more than a used engine pulled from a junkyard. Rebuilt engines fall somewhere in between, offering a balance of cost and reliability.

- Cylinder Head Material: Aluminum cylinder heads are generally lighter and offer better heat dissipation than cast iron heads. This translates to improved performance, but also a higher price tag.

- Intake Manifold Material: The intake manifold distributes the air/fuel mixture to the cylinders. Options range from cast iron to aluminum to composite materials, each with varying costs and performance characteristics.

- Fuel Delivery System: Carbureted engines are generally less expensive than fuel-injected engines. Fuel injection offers better fuel economy and performance, but requires more complex electronics and sensors, which add to the cost.

- Engine Block Material: As with heads, aluminum blocks are lighter than cast iron, enhancing performance, but carrying a higher cost.

- Crankshaft, Connecting Rods, Pistons: The quality and materials of these internal components greatly impact price. Forged internals (crankshaft, rods, and pistons) are stronger and more durable than cast internals, making them ideal for high-performance applications, but also more expensive.

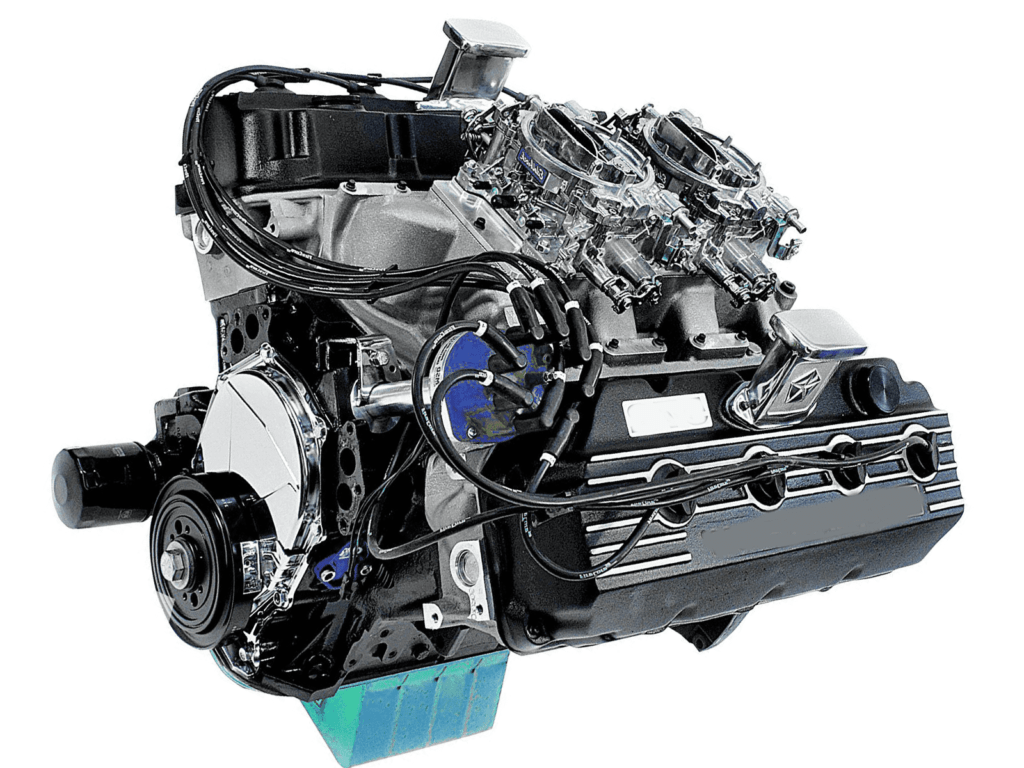

The main components of a V8, all contributing to the overall cost, include:

- Engine Block: The foundation of the engine, housing the cylinders, crankshaft, and other vital components.

- Cylinder Heads: Located on top of the engine block, they contain the intake and exhaust valves, as well as the combustion chambers.

- Pistons: Move up and down within the cylinders, compressing the air/fuel mixture.

- Connecting Rods: Connect the pistons to the crankshaft.

- Crankshaft: Converts the reciprocating motion of the pistons into rotary motion, which is then transmitted to the transmission.

- Camshaft: Controls the opening and closing of the intake and exhaust valves.

- Intake Manifold: Distributes the air/fuel mixture to the cylinders.

- Exhaust Manifold (or Headers): Collects exhaust gases from the cylinders.

- Oil Pan: Holds the engine oil.

- Water Pump: Circulates coolant through the engine to regulate temperature.

- Distributor (or Ignition System): Provides the spark to ignite the air/fuel mixture.

How a V8 Works (Briefly)

Understanding the basic operation of a V8 helps you appreciate the complexity, and therefore, the cost. The four-stroke cycle (intake, compression, combustion, exhaust) happens in each cylinder. Fuel and air enter the cylinder (intake), the piston compresses the mixture (compression), the spark plug ignites the mixture (combustion), and the exhaust gases are expelled (exhaust). This repeated process drives the pistons, which in turn rotate the crankshaft, producing power. The V configuration (two banks of cylinders angled away from each other) helps balance the engine and reduce overall length.

Real-World Use: Basic Troubleshooting & Cost Implications

Let's say you have a misfire. Here's how understanding V8 components can help you troubleshoot and estimate costs:

- Check Engine Light: Scan the OBD-II (On-Board Diagnostics II) system. A code like P0301 (cylinder 1 misfire) narrows down the problem. An OBD-II scanner is a very useful tool.

- Possible Causes: Could be a bad spark plug ($5-10), a faulty ignition coil ($30-100), a clogged fuel injector ($50-200), or even a more serious issue like a burned valve (potentially requiring a cylinder head rebuild - $500+).

- Diagnosis: Swap the spark plug with another cylinder. If the misfire moves, it's the plug. Do the same with the ignition coil. Use a multimeter to test the resistance of the fuel injector. A compression test can reveal valve issues.

- Cost Estimation: Identifying the faulty component early saves you money. Replacing a spark plug is a simple DIY job. Replacing a fuel injector is a bit more involved. A cylinder head rebuild requires specialized tools and knowledge.

Simple fixes like changing spark plugs or wires are relatively inexpensive. However, problems that require removing cylinder heads or the engine itself will significantly increase labor costs.

Safety Considerations

Working on a V8 engine involves some serious safety risks. Always disconnect the battery before working on the electrical system to avoid shocks. Fuel systems are highly flammable – take precautions to prevent fires. Be extremely careful when working with the cooling system. Hot coolant can cause severe burns. Wear safety glasses to protect your eyes from flying debris. And always use proper lifting equipment when removing or installing heavy components like the engine block or cylinder heads. Furthermore, be sure to properly dispose of used oil and other fluids at a designated recycling center.

Also, beware of pressurized components. The fuel injection system can retain high pressure even after the engine is off. Relieve the pressure before disconnecting fuel lines. Similarly, the air conditioning system contains refrigerant under high pressure. Only qualified technicians should handle refrigerant.

Finally, be sure to properly support the vehicle when working underneath it. Never rely solely on a jack. Use jack stands that are rated for the weight of the vehicle.

Cost Breakdown Examples:

- Junkyard Engine: $500-$2000 (depending on condition and rarity). Expect to spend extra on gaskets, seals, and potentially some replacement parts.

- Rebuilt Engine: $2000-$5000 (depending on the extent of the rebuild and the quality of the parts used). Offers a good balance of cost and reliability.

- Crate Engine (Basic): $4000-$8000 (ready to install, but may require additional accessories).

- Crate Engine (Performance): $8000+ (high horsepower, often with forged internals and aftermarket components).

These are just ballpark figures. Prices can vary significantly depending on your location, the specific engine model, and the supplier.

Ultimately, the cost of a V8 engine is a multifaceted equation. By understanding the various factors involved, you can make informed decisions and avoid costly surprises. Take your time, do your research, and don't be afraid to ask for help from experienced mechanics or fellow enthusiasts.