How Much To Replace Car Ac

So, your car AC is blowing warm air, and you're contemplating tackling the repair yourself? Excellent! Knowing the ins and outs of your car's air conditioning system is a valuable skill, and while it can be a complex system, understanding the fundamentals will save you money and frustration. This article will break down the components, functionality, and troubleshooting of your car's AC, helping you determine if a DIY replacement is feasible and, if so, how to proceed safely and effectively. We'll also address the crucial question of cost.

Purpose: Why Understand Your Car's AC System?

Whether you're aiming to perform repairs, upgrade your system, or simply understand how your car works, a solid grasp of your AC system is essential. Specifically, understanding the system helps with:

- Troubleshooting: Pinpoint the exact cause of your AC failure, avoiding unnecessary replacements.

- Repair: Replace faulty components yourself, saving on labor costs.

- Maintenance: Proactively maintain your system to prevent future breakdowns.

- Modifications: If you're into modding, you might want to upgrade components for better performance (e.g., a larger condenser).

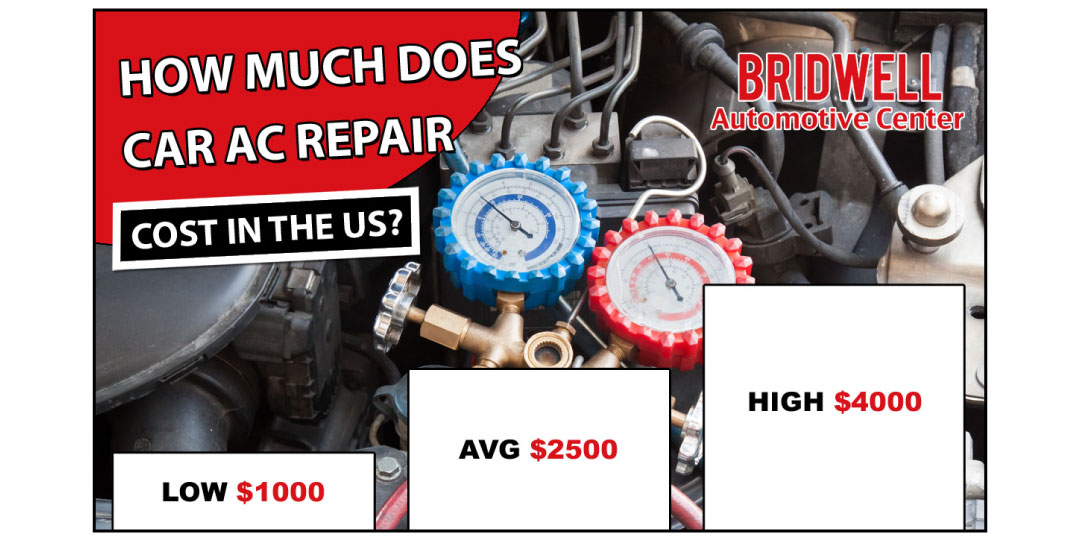

- Estimating Repair Costs: Knowing the components involved allows you to accurately estimate the cost of a professional repair if DIY isn't an option.

This article prepares you to make informed decisions about your AC system and whether you can handle the replacement yourself. And to support your journey, we can supply you with a detailed diagram of your specific vehicle's AC system. You'll find download link at the end.

Key Specs and Main Parts

A car's AC system is a closed-loop refrigeration cycle that removes heat from the cabin. The main components, and their approximate replacement costs (excluding labor), are:

- Compressor: The heart of the system, responsible for compressing the refrigerant. A new compressor can cost anywhere from $200 to $800, depending on the make and model of your car, and whether it's new or remanufactured. A failed compressor is a common cause of AC failure.

- Condenser: Located in front of the radiator, the condenser dissipates heat from the refrigerant. Replacement condensers typically range from $80 to $300.

- Evaporator: Situated inside the dashboard, the evaporator absorbs heat from the cabin air. Evaporator replacement is labor-intensive, often requiring dashboard removal, and the part itself can cost $150-$500.

- Expansion Valve (or Orifice Tube): Regulates the flow of refrigerant into the evaporator, causing a pressure drop and thus, cooling. These are relatively inexpensive, ranging from $20 to $80.

- Receiver Drier (or Accumulator): Filters debris and absorbs moisture from the refrigerant. Replacement costs are usually between $30 and $100. It's *crucial* to replace this whenever you open the system, as it becomes saturated with moisture.

- Refrigerant Lines: These hoses and pipes carry the refrigerant throughout the system. Damaged lines need to be replaced. Expect to pay $50-$200 per line.

- Pressure Switches: These sensors monitor refrigerant pressure and prevent the system from operating under abnormal conditions. They typically cost $20-$60.

Understanding AC System Symbols

AC system diagrams use standard symbols to represent different components and lines. Here's a breakdown:

- Solid Lines: Represent refrigerant lines carrying liquid or gaseous refrigerant.

- Dashed Lines: Typically represent control lines, such as vacuum lines or electrical wiring connecting sensors and switches.

- Compressor Symbol: Usually depicted as a circular pump-like symbol.

- Condenser Symbol: Often shown as a series of zig-zag lines.

- Evaporator Symbol: Similar to the condenser symbol, but often with a different shape or orientation.

- Expansion Valve/Orifice Tube Symbol: A small valve or restriction symbol.

- Receiver Drier/Accumulator Symbol: Usually represented as a cylindrical tank with desiccant material inside.

- Pressure Switch Symbol: A small electrical switch symbol.

- Directional Arrows: Indicate the flow of refrigerant.

- Color Coding (if present): Some diagrams use color to distinguish between high-pressure and low-pressure lines. Typically, red indicates high pressure, and blue indicates low pressure.

How It Works: The Refrigeration Cycle

The AC system operates on the principles of thermodynamics. Here's a simplified explanation:

- Compression: The compressor compresses the low-pressure, gaseous refrigerant, increasing its temperature and pressure.

- Condensation: The high-pressure, hot refrigerant flows to the condenser, where it dissipates heat to the outside air and turns into a high-pressure, warm liquid.

- Metering: The high-pressure, warm liquid refrigerant passes through the expansion valve (or orifice tube), which creates a pressure drop. This rapid pressure drop causes the refrigerant to evaporate and become very cold.

- Evaporation: The cold, low-pressure refrigerant flows into the evaporator. Here, it absorbs heat from the air blowing across the evaporator core, cooling the air that enters the cabin.

- Suction: The low-pressure, now gaseous, refrigerant returns to the compressor, completing the cycle. The receiver drier filters and removes moisture from the refrigerant before it enters the compressor.

Real-World Use: Basic Troubleshooting Tips

Before diving into a full replacement, try these troubleshooting steps:

- Check the Fuses and Relays: A blown fuse or faulty relay is a common cause of AC failure. Consult your owner's manual for the AC fuse and relay locations.

- Inspect the Compressor Clutch: With the engine running and the AC turned on, observe the compressor clutch. It should engage and disengage. If it's not engaging, the compressor may not be receiving power, or the clutch itself may be faulty.

- Look for Leaks: Inspect refrigerant lines, the compressor, condenser, and evaporator connections for signs of leaks (oily residue). A UV dye kit can help locate small leaks.

- Check Refrigerant Pressure: Using a manifold gauge set, measure the high-side and low-side pressures. Incorrect pressures indicate a refrigerant leak, a clogged orifice tube, or a faulty compressor. *Proper training and tools are necessary for this step*.

- Smell Test: A musty odor often indicates a mold or mildew problem in the evaporator core. This can be addressed with a cleaner specifically designed for AC systems.

If these basic checks don't resolve the issue, it's likely that a component needs replacement. Based on your findings, you can then determine whether you can handle the repair yourself or if you should seek professional help. For instance, replacing the condenser or receiver drier is generally a straightforward DIY task. However, compressor or evaporator replacement can be much more involved, potentially requiring specialized tools and knowledge.

Safety First: Risky Components and Procedures

Working on AC systems involves risks, primarily due to high pressures and potentially hazardous refrigerants.

- Refrigerant Handling: Refrigerants can cause frostbite on contact and are harmful if inhaled. Always wear safety glasses and gloves when working with refrigerant. Never vent refrigerant into the atmosphere, as it's illegal and environmentally damaging. Use a refrigerant recovery machine to properly recover the refrigerant before opening the system.

- High Pressure: The high-pressure side of the system can reach several hundred PSI. Exercise extreme caution when disconnecting lines or fittings. Make sure the system is properly discharged before opening any lines.

- Electrical Components: Be mindful of electrical components, such as the compressor clutch and pressure switches. Disconnect the battery before working on any electrical connections.

- Sharp Edges: The condenser and evaporator fins can be sharp. Wear gloves to protect your hands.

Important Disclaimer: This information is for educational purposes only and should not be considered a substitute for professional advice. If you are not comfortable working on your car's AC system, seek the help of a qualified technician.

Before you proceed with any repairs, be sure to consult your vehicle's service manual for specific instructions and torque specifications. This will help ensure that you perform the repairs correctly and safely.

Now that you have a better understanding of your car's AC system, you're in a much better position to diagnose problems, estimate repair costs, and determine whether you can handle the replacement yourself. Remember to prioritize safety and consult your vehicle's service manual for specific instructions.

To further assist you in your repair endeavors, we have a detailed AC system diagram available for download. This diagram provides a visual representation of the system, including the location of components and the routing of refrigerant lines. This invaluable tool can aid you in locating and replacing faulty components with confidence. Contact us to obtain your diagram.