How Reliable Is A Nissan Rogue

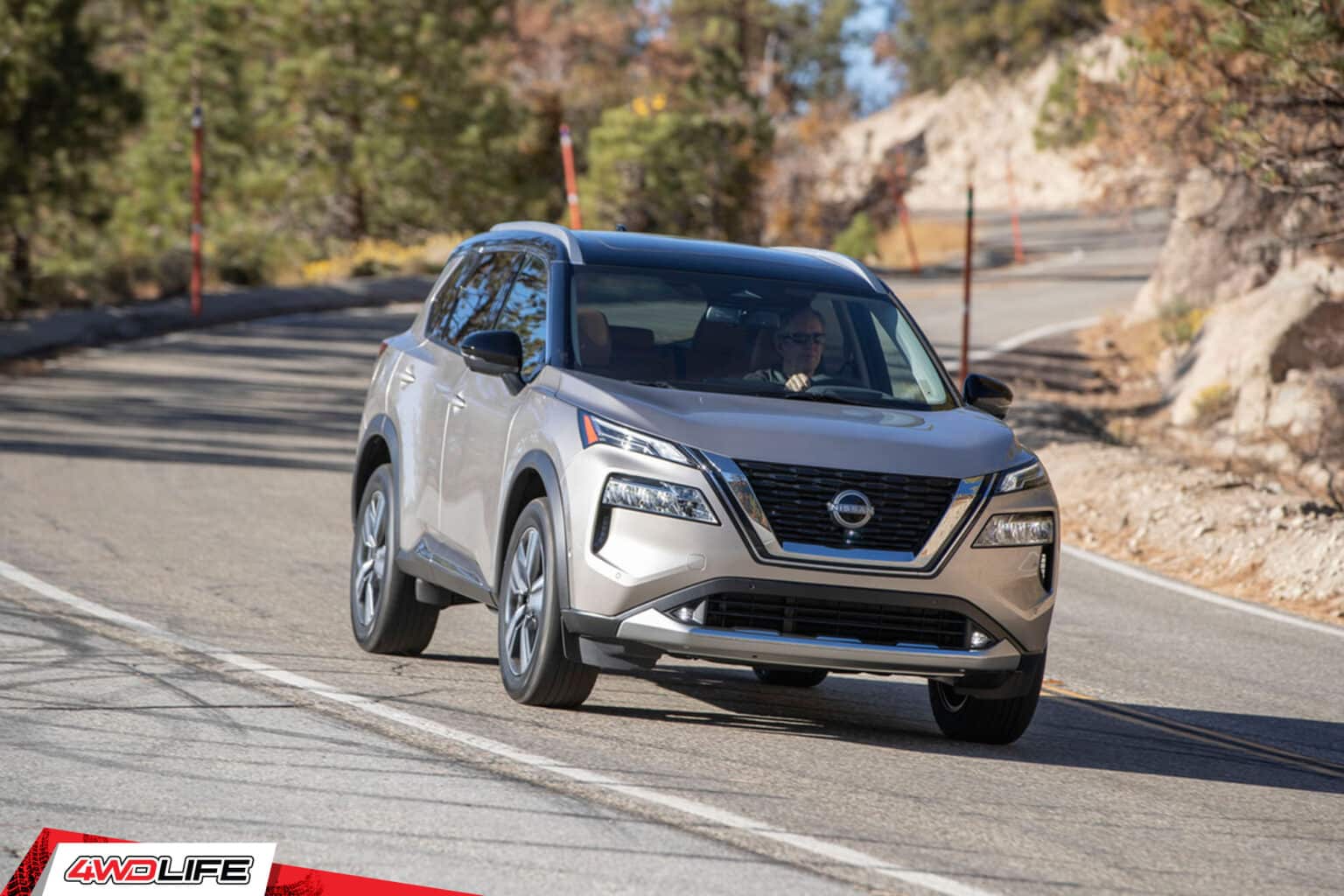

Alright, let's talk about the reliability of the Nissan Rogue. It's a popular SUV, but like any vehicle, its longevity and dependability depend on several factors. We're going to dive into some of the key areas that affect its reliability and what you can do to keep yours running smoothly. We'll be using a conceptual diagram of the Rogue's vital systems to illustrate these points, and you can think of this explanation as the companion to that visual aid.

Why We Need to Talk Reliability (and Diagrams)

Understanding the potential trouble spots in your Rogue is crucial for preventative maintenance and informed repairs.

Purpose: A detailed diagram, combined with this explanation, empowers you to diagnose issues, perform basic maintenance, and even tackle some DIY repairs with greater confidence. Whether you're trying to save money on mechanics' bills or simply want to understand your vehicle better, this knowledge is invaluable.It also helps you understand if a repair is worth doing based on the age, mileage, and overall condition of your vehicle.

Key Specs and Main Parts Affecting Reliability

Several core components significantly impact the Rogue's overall reliability. Let's break them down:

Engine (QR25DE, MR20DD, KR15DDT)

The engine is the heart of any vehicle. The Rogue has seen a few different engine options over the years. The QR25DE (2.5L inline-4) was common in earlier models. Later models have used the MR20DD (2.0L inline-4) and more recently the KR15DDT (1.5L Turbo inline-3). Engine reliability is heavily influenced by oil changes. Sludging, caused by infrequent oil changes or using the wrong oil, is a common culprit for premature engine wear and eventual failure. Oil pressure, monitored by a sensor, is crucial. Low oil pressure can indicate serious problems. The diagram would illustrate the oil flow path and the location of the oil pressure sensor.

Continuously Variable Transmission (CVT)

The CVT is often cited as the Rogue's Achilles' heel. CVTs, in general, are more sensitive to maintenance than traditional automatic transmissions. They use a belt and pulley system to provide a virtually infinite number of gear ratios, which improves fuel economy but can lead to issues if not properly maintained. Regular fluid changes (using the correct Nissan CVT fluid NS-2, NS-3 or the newer NS-CVT depending on model year) are absolutely critical. Overheating is a major cause of CVT failure. The diagram highlights the CVT fluid cooler and its connection to the radiator. Pay close attention to any shuddering or unusual noises coming from the transmission, as these can be early warning signs.

Electronics

Modern cars are heavily reliant on electronics. The Rogue is no exception. Common electronic issues can range from faulty sensors to problems with the infotainment system. The Engine Control Unit (ECU) is responsible for controlling many of the engine's functions, and a failing ECU can lead to a variety of performance problems. Diagnostic Trouble Codes (DTCs), read by an OBD-II scanner, can pinpoint specific electronic issues. Wiring harnesses can also degrade over time, leading to shorts and other electrical problems. The diagram might show the location of key sensors and the ECU, along with simplified wiring schematics.

Suspension

The Rogue's suspension system is relatively straightforward, typically consisting of MacPherson struts in the front and a multi-link setup in the rear. Common wear items include struts, shocks, ball joints, and tie rod ends. Listen for clunking noises when going over bumps, which can indicate worn suspension components. Rust, especially in areas with harsh winters, can accelerate suspension wear. The diagram would showcase the various suspension components and their mounting points.

Symbols and Colors: Deciphering the Diagram

Understanding the diagram requires knowing the symbols used. Here are some common conventions:

- Solid lines: Typically represent fluid lines (oil, coolant, transmission fluid).

- Dashed lines: Often indicate electrical wiring or vacuum lines.

- Colors: Colors are used to differentiate systems. For example, red might indicate the fuel system, blue the cooling system, and yellow the electrical system.

- Icons: Specific icons represent components like sensors, pumps, valves, and actuators. A resistor will have a squiggly line, a capacitor will have two parallel lines, etc.

The diagram will come with a legend which will provide specifics on all symbols and colors used.

How It Works: A System-Level View

The diagram helps illustrate how the different systems interact. For example, the engine's cooling system is crucial for preventing overheating, which can damage the engine and CVT. The diagram would show the flow of coolant through the engine block, radiator, and heater core. It also highlights the thermostat, which regulates coolant temperature. The CVT cooler, often integrated with the radiator, relies on the cooling system to dissipate heat generated by the transmission. Understanding these interconnections is key to diagnosing problems effectively.

Real-World Use: Basic Troubleshooting

Let's say your Rogue is experiencing rough idling. Here's how you could use the diagram and your understanding to troubleshoot:

- Check the basics: Is the check engine light on? If so, use an OBD-II scanner to read the DTCs.

- Consult the diagram: Locate the Idle Air Control (IAC) valve or throttle body (depending on the engine). The diagram shows its location and connections.

- Inspect the IAC/Throttle Body: Check for any visible signs of dirt or damage. Clean the throttle body if necessary.

- Check for vacuum leaks: The diagram shows the vacuum lines connected to the engine. Inspect these lines for cracks or leaks.

This is a simplified example, but it demonstrates how the diagram can guide your troubleshooting process.

Safety First: Identifying Risky Components

Working on cars can be dangerous. Here are some components in the Rogue that require extra caution:

- Fuel System: Fuel is highly flammable. Always disconnect the negative battery cable before working on the fuel system. Avoid sparks or open flames.

- Electrical System: High-voltage components can deliver a dangerous shock. Disconnect the battery and be careful when working around the electrical system. Always double-check wiring diagrams before making any connections.

- Exhaust System: Exhaust components get extremely hot. Allow the exhaust system to cool completely before working on it.

- Suspension System: Springs can be under considerable tension. Use spring compressors when removing or installing struts.

Always wear appropriate safety gear, including safety glasses and gloves. If you are unsure about any procedure, consult a qualified mechanic.

In conclusion, the Nissan Rogue's reliability, like any vehicle, relies on regular maintenance and addressing issues promptly. By understanding the key components, their interconnections, and potential failure points, you can significantly improve the longevity of your Rogue. The detailed diagram, which is available for download, serves as a valuable tool for diagnosis, repair, and preventative maintenance.

We have the file that contains this diagram. This comprehensive resource, detailing the Rogue's engine, transmission, electrical system, and more, is designed to give you the visual information necessary to approach repairs and maintenance with confidence.