How To Adjust Engine Idle Speed

The gentle hum of a well-tuned engine at idle is a symphony of mechanical precision. But what happens when that hum turns into a rough cough or a racing roar? Often, the culprit is an improperly adjusted idle speed. This guide delves into the intricacies of adjusting engine idle speed, exploring the mechanics, techniques, and considerations involved in achieving that perfect, smooth idle.

The Problem: Idle Speed Gone Astray

Imagine this: you pull up to a stoplight, and your car vibrates like a paint mixer. Or perhaps the opposite – the engine revs unnecessarily high, wasting fuel and making you look like you're eager to drag race the minivan next to you. These are common symptoms of an incorrect idle speed. An engine's idle speed, measured in revolutions per minute (RPM), is the speed at which the engine runs when the throttle is closed and no driver input is applied. It's a crucial setting that affects fuel efficiency, emissions, and overall engine smoothness.

Several factors can cause idle speed to drift. Wear and tear on engine components, changes in ambient temperature, vacuum leaks, and even carbon buildup in the throttle body can all contribute to an unstable idle. Left unaddressed, an incorrect idle speed can lead to poor fuel economy, increased emissions, difficulty starting, and even stalling.

Understanding the Idle Control System: A Mechanical Symphony

To understand how to adjust idle speed, it's essential to grasp the underlying mechanics. The idle control system is a relatively simple, yet critical, part of the engine management system. Its primary goal is to maintain a consistent idle speed, regardless of external factors like engine temperature or electrical load.

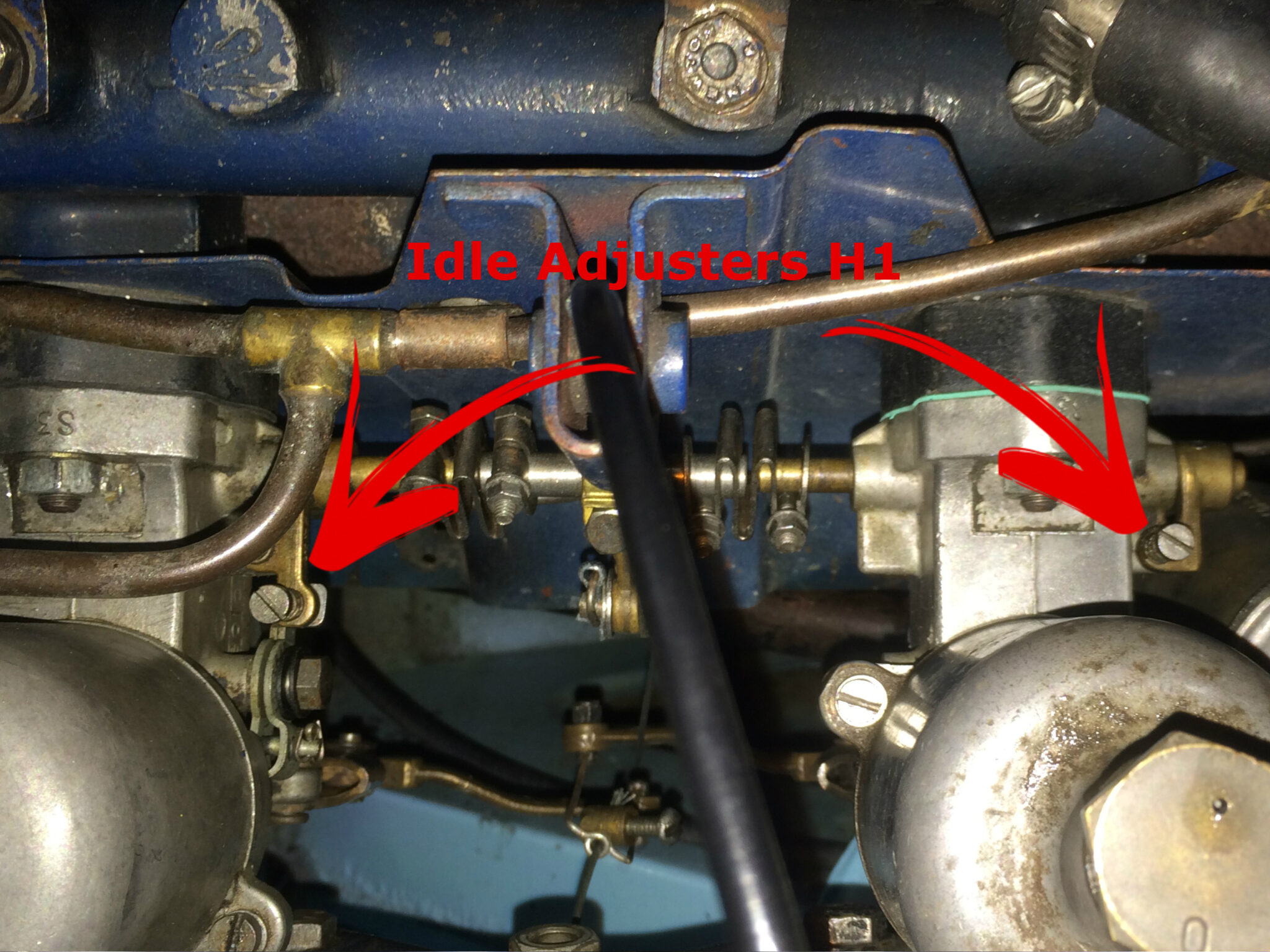

Before the Electronic Age: Carburetor Idle Adjustment: In older, carbureted engines, idle speed was typically controlled by a simple mechanical screw that adjusted the throttle plate's resting position. Turning the screw in increased the throttle opening, allowing more air and fuel into the engine and raising the idle speed. Conversely, turning it out decreased the opening, lowering the idle speed. These systems often had a second screw that controlled the fuel/air mixture. Getting both just right was an art form. Think of it like adjusting the volume on a record player – too low, and you can't hear it; too high, and it distorts.

The Rise of Fuel Injection and Electronic Control: Modern engines use fuel injection systems controlled by an Engine Control Unit (ECU). The ECU monitors various sensors, including engine temperature, manifold absolute pressure (MAP), and throttle position sensor (TPS), to determine the optimal fuel and air mixture and ignition timing. In these systems, idle speed is typically controlled by an Idle Air Control (IAC) valve or a similar mechanism.

The Idle Air Control (IAC) Valve:

The IAC valve is essentially a small electric motor that controls the amount of air bypassing the throttle plate when it's closed. The ECU commands the IAC valve to open or close, allowing more or less air into the intake manifold. This precise control allows the ECU to maintain a steady idle speed under various conditions.

How It Works:

- Sensors Report: Sensors transmit data to the ECU about engine conditions.

- ECU Analyzes: The ECU processes the sensor data and compares the current idle speed to the target idle speed stored in its memory.

- IAC Valve Adjusts: If the idle speed is too low, the ECU commands the IAC valve to open further, allowing more air to bypass the throttle plate and increasing the idle speed. If the idle speed is too high, the ECU commands the IAC valve to close, reducing the airflow and lowering the idle speed.

- Feedback Loop: The ECU continuously monitors the idle speed and adjusts the IAC valve as needed to maintain the target idle speed.

Adjusting Idle Speed: A Step-by-Step Guide

Adjusting idle speed varies depending on the vehicle's age and type of engine management system. Here's a general guide for both carbureted and fuel-injected engines.

Carbureted Engines:

- Warm-Up the Engine: Ensure the engine is at its normal operating temperature.

- Locate the Idle Speed Screw: This screw is usually located near the throttle linkage on the carburetor. Refer to your vehicle's service manual for the exact location.

- Locate the Mixture Screw: Find the screw that adjusts the fuel/air mixture; it's usually very close to the idle screw.

- Adjust the Idle Speed: Using a screwdriver, turn the idle speed screw to increase or decrease the idle speed. Use a tachometer to monitor the RPM and adjust it to the manufacturer's specifications (usually found in the vehicle's service manual or on a sticker under the hood).

- Adjust the Mixture: Adjust the mixture screw to achieve the smoothest idle with the highest vacuum reading. Some engines will have a specific procedure to adjust the mixture; this will depend on the type of carburetor used.

- Fine-Tune: Fine-tune both screws until the engine idles smoothly at the correct RPM.

Fuel-Injected Engines:

Adjusting idle speed on fuel-injected engines is generally more complex and often requires specialized tools. In many cases, the ECU automatically controls the idle speed and does not allow for manual adjustment. However, some vehicles may have a manual adjustment procedure.

- Consult the Service Manual: This is crucial! The service manual will outline the specific procedure for your vehicle. Some manufacturers advise against manual adjustment.

- Check for Diagnostic Trouble Codes (DTCs): Use an OBD-II scanner to check for any DTCs related to the idle control system. Address any issues before attempting to adjust the idle speed.

- Throttle Body Cleaning: Carbon buildup in the throttle body can interfere with the IAC valve's operation. Cleaning the throttle body can often resolve idle speed issues.

- IAC Valve Inspection: Inspect the IAC valve for signs of damage or contamination. Replace the valve if necessary.

- Manual Adjustment (If Applicable): Some vehicles may have a manual adjustment screw on the throttle body. Follow the service manual's instructions carefully to adjust the idle speed. Improper adjustment can damage the engine or the ECU.

- ECU Reset: After making any adjustments, it may be necessary to reset the ECU to allow it to learn the new idle settings. This can often be done by disconnecting the battery for a period of time or by using a scan tool.

Pros and Cons of Adjusting Idle Speed

Pros:

- Improved Fuel Economy: Correctly adjusted idle speed can optimize fuel consumption at idle.

- Reduced Emissions: Proper idle speed contributes to lower emissions.

- Smoother Idle: Eliminates rough idling and vibrations.

- Prevents Stalling: Prevents the engine from stalling at idle.

Cons:

- Potential for Damage: Incorrect adjustment can damage the engine or the ECU, especially on modern vehicles.

- Complexity: Adjusting idle speed on fuel-injected engines can be complex and require specialized tools.

- Not a Universal Solution: Idle speed issues can be caused by various underlying problems, such as vacuum leaks or faulty sensors. Adjusting the idle speed may only mask the underlying problem.

Use Cases and Manufacturer Examples

Classic Car Restoration: In classic car restoration, accurately setting the idle speed and mixture on carbureted engines is crucial for achieving optimal performance and authenticity. Many vintage car enthusiasts spend countless hours perfecting their carburetor adjustments.

Off-Road Vehicles: In off-road vehicles, a slightly higher idle speed can be beneficial for maintaining engine power and preventing stalling in challenging terrain. However, excessive idle speed can lead to increased fuel consumption and reduced control.

Manufacturer Examples:

- Honda: Honda's fuel-injected engines typically rely on the ECU to control idle speed automatically. Manual adjustment is generally not recommended.

- Ford: Some older Ford vehicles with fuel injection may have a manual idle speed adjustment screw on the throttle body. However, later models rely entirely on the ECU.

- GM: Similar to Ford, older GM vehicles may have a manual adjustment screw, while newer models are fully controlled by the ECU.

Real-World Insights and Recommendations

Adjusting engine idle speed can be a rewarding experience, but it's crucial to approach it with caution and knowledge. Before making any adjustments, consult your vehicle's service manual and understand the specific requirements and procedures for your engine. If you're unsure about any step, it's best to seek the assistance of a qualified mechanic.

Remember: Idle speed adjustment is not a magic bullet. If you're experiencing persistent idle speed problems, it's essential to diagnose and address the underlying cause, such as vacuum leaks, faulty sensors, or carbon buildup. Cleaning the throttle body and inspecting the IAC valve are often good starting points.

In the age of sophisticated engine management systems, the art of manually adjusting idle speed is becoming increasingly rare. However, understanding the principles behind idle control and the mechanics of different systems can provide valuable insights into how your engine works and empower you to diagnose and resolve common engine problems. Approach this task with patience, attention to detail, and a healthy respect for the complexity of the modern internal combustion engine.