How To Adjust Timing On A Car

Alright, let's dive into the world of ignition timing. Understanding and adjusting your car's timing can unlock performance, improve fuel economy, and help diagnose engine issues. This isn't a beginner's task, so I'm assuming you're already comfortable with basic car maintenance. We'll cover the 'why,' the 'what,' and the 'how' of ignition timing adjustment.

Purpose of Timing Adjustment

Why bother messing with timing? The main purpose is to ensure the spark plug fires at the optimal moment to ignite the air-fuel mixture in the cylinder. This "optimal moment" changes depending on engine speed (RPM) and load. Properly adjusted timing maximizes combustion efficiency, leading to:

- Improved Performance: More power and torque, especially at higher RPMs.

- Better Fuel Economy: More complete combustion extracts more energy from each drop of fuel.

- Reduced Emissions: Cleaner burning reduces harmful exhaust gases.

- Prevention of Engine Damage: Improper timing can lead to knocking or pre-ignition, severely damaging the engine.

- Diagnostic Aid: Changes in timing behavior can indicate underlying engine problems.

Whether you're diagnosing a rough idle, trying to squeeze more power out of your engine, or simply trying to learn more about how your car works, understanding ignition timing is essential.

Key Specs and Main Parts

Before we get our hands dirty, let's familiarize ourselves with the critical components and specifications:

Main Parts Involved:

- Crankshaft Position Sensor (CKP): This sensor monitors the position of the crankshaft and sends this information to the engine control unit (ECU). This data is crucial for determining when to fire the spark plugs.

- Camshaft Position Sensor (CMP): Provides information on the position of the camshaft, allowing the ECU to determine which cylinder is on its compression stroke. This is especially important for sequential fuel injection and accurately controlling ignition.

- Distributor (Older Engines): In older vehicles, the distributor mechanically distributes the high-voltage spark to the correct spark plug. Timing is adjusted by rotating the distributor body.

- Ignition Coil(s): The coil transforms low voltage from the battery into the high voltage needed to create a spark. Modern engines often have coil-on-plug (COP) systems, where each cylinder has its own coil.

- Spark Plugs: The spark plugs ignite the air-fuel mixture.

- Engine Control Unit (ECU): The "brain" of the engine, the ECU processes data from various sensors, including the CKP and CMP, and controls the ignition timing, fuel injection, and other engine parameters.

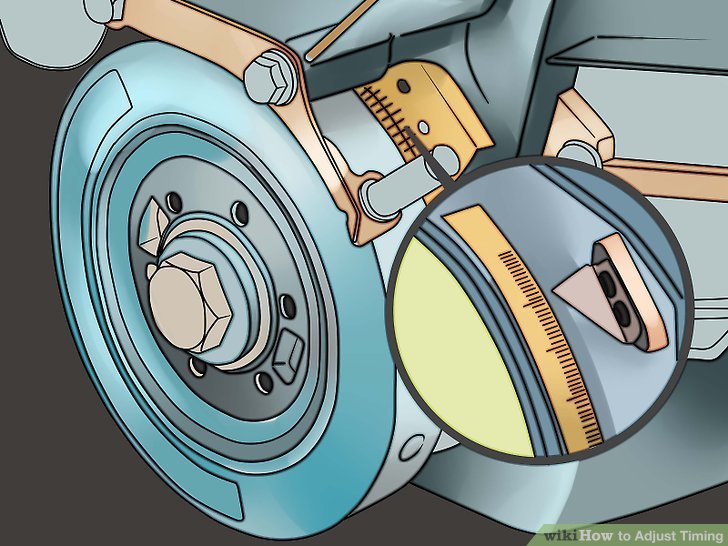

- Timing Light: A strobe light used to visually verify the ignition timing. It flashes when a spark plug fires, allowing you to compare the crankshaft pulley markings to the timing marks.

Key Specifications:

- Base Timing: The ignition timing at idle speed, usually specified in degrees Before Top Dead Center (BTDC). This is your starting point for adjustments.

- Timing Advance: The amount the ignition timing is advanced (fired earlier) as engine speed increases. This is often controlled by the ECU based on engine load and other factors.

- Top Dead Center (TDC): The point where the piston is at the very top of its stroke.

- Degrees BTDC (Before Top Dead Center): The number of degrees the crankshaft is rotated *before* the piston reaches TDC when the spark plug fires. Higher BTDC values equate to more advance.

- Degrees ATDC (After Top Dead Center): The number of degrees the crankshaft is rotated *after* the piston reaches TDC when the spark plug fires.

- Knock Sensor: A sensor that detects engine knocking or detonation. The ECU uses this information to retard (delay) the timing to prevent engine damage.

How It Works (Simplified)

The engine's operation relies on precise timing. The Crankshaft Position Sensor (CKP) tells the ECU exactly where the crankshaft is in its rotation. The Camshaft Position Sensor (CMP) tells the ECU which cylinder is on its compression stroke. Using this information, the ECU calculates the optimal time to fire the spark plug. The ECU then sends a signal to the ignition coil, which generates a high-voltage spark that jumps the gap at the spark plug, igniting the air-fuel mixture. As engine speed increases, the ECU advances the timing, meaning it fires the spark plug earlier in the compression stroke. This allows more time for the combustion process to complete, maximizing power output. Too much advance, however, can lead to knocking (detonation), which is harmful to the engine.

In older vehicles with distributors, the timing is adjusted manually by rotating the distributor body. This changes the relationship between the distributor rotor and the distributor cap terminals, effectively advancing or retarding the spark timing. The timing light is used to visually verify that the timing is set correctly.

Real-World Use: Basic Troubleshooting

Here are a few troubleshooting scenarios where adjusting timing might be necessary:

- Rough Idle: Incorrect timing can cause a rough or unstable idle. Check the base timing and adjust it to the manufacturer's specifications.

- Poor Fuel Economy: Retarded timing can lead to poor fuel economy. Experiment with slightly advancing the timing, but be cautious of knocking.

- Knocking or Pinging: This indicates that the timing is too advanced. Retard the timing until the knocking disappears.

- Lack of Power: Incorrect timing can rob the engine of power. Verify the timing is within spec and consider slightly advancing it for improved performance (if appropriate for your engine and fuel grade).

Important: Always consult your vehicle's service manual for the correct timing specifications and adjustment procedures. Don't just guess! Incorrect timing can damage your engine.

Using a Timing Light: A timing light is crucial for setting base timing on older vehicles with distributors. Connect the timing light to the battery and the number one spark plug wire. Start the engine and point the timing light at the crankshaft pulley. The strobe light will flash each time the spark plug fires. Compare the markings on the pulley to the timing marks on the engine. Adjust the distributor until the timing mark aligns with the specified degree mark.

Safety Considerations

Working on the ignition system involves high voltage and moving parts. Here's what you need to keep in mind:

- High Voltage: The ignition system generates extremely high voltage. Never touch any ignition components while the engine is running or the ignition is turned on. You could receive a dangerous electric shock.

- Moving Parts: Keep your hands and clothing away from moving engine parts, such as the belts and pulleys.

- Hot Surfaces: The exhaust manifold and other engine components can get extremely hot. Avoid touching them to prevent burns.

- Disconnect the Battery: Whenever possible, disconnect the negative battery terminal before working on the ignition system. This reduces the risk of electrical shock and accidental starting.

- Work in a Well-Ventilated Area: Engine exhaust contains carbon monoxide, a deadly gas. Always work in a well-ventilated area when the engine is running.

Adjusting timing on modern cars with electronic ignition systems often requires specialized diagnostic tools to communicate with the ECU. The process involves changing parameters within the ECU's software, which carries inherent risks if not performed correctly. Exercise extreme caution when modifying ECU settings.